Insulating Fire Brick - High Quality Clay Refractory Insulating Fire Brick for Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

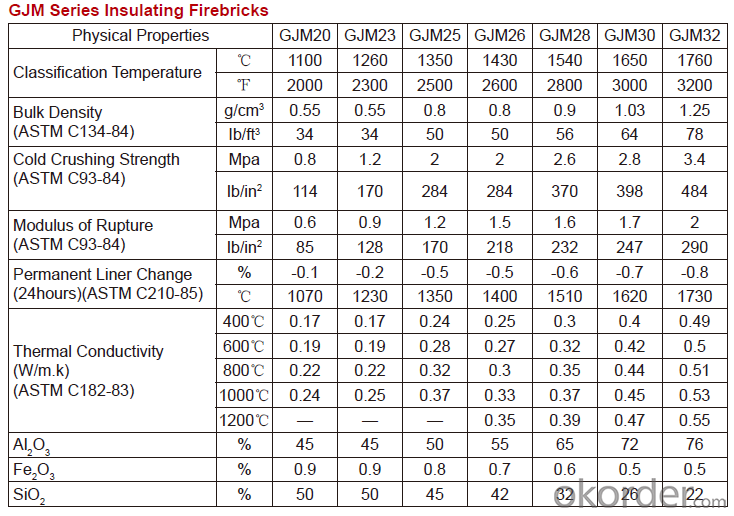

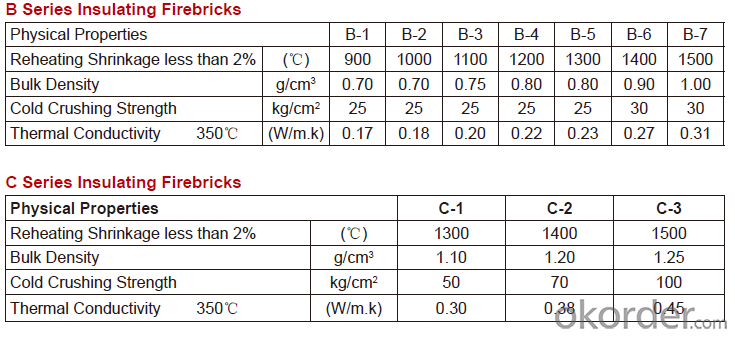

Insulating Fire Brick main feature

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How do insulating fire bricks affect the overall fire safety of a structure?

- Insulating fire bricks greatly enhance the fire safety of a structure. Due to their high thermal resistance, these bricks effectively prevent the spread of heat, reducing the risk of structural damage and minimizing the chance of fire spreading to adjacent areas. Additionally, their low thermal conductivity helps to retain heat within the furnace or fireplace, improving energy efficiency and reducing the likelihood of accidental fires.

- Q: How do insulating fire bricks help improve the efficiency of heat treatment processes?

- Insulating fire bricks play a crucial role in improving the efficiency of heat treatment processes. These bricks are specially designed to have low thermal conductivity, which means they are excellent at insulating against heat transfer. This insulation property helps to minimize heat loss and maintain high temperatures within the heat treatment furnaces or kilns. By using insulating fire bricks, the heat treatment process can achieve higher temperatures more efficiently. The bricks act as a barrier, preventing the heat from escaping the furnace and ensuring that it remains concentrated inside. This not only enhances the overall energy efficiency of the heat treatment process but also reduces the need for excessive fuel consumption. Furthermore, insulating fire bricks also contribute to a reduction in the heating time required for the heat treatment process. Due to their low thermal conductivity, they minimize the heat loss to the surrounding environment, allowing the furnace to reach the desired temperature quickly. This not only saves time but also reduces the energy consumption associated with prolonged heating. In addition to thermal insulation, insulating fire bricks also provide mechanical strength and durability. They can withstand high temperatures without undergoing significant structural changes or damage. This ensures that the bricks maintain their insulating properties over an extended period, allowing for consistent and efficient heat treatment processes. Moreover, the use of insulating fire bricks helps to create a more controlled and stable thermal environment within the furnace or kiln. Their insulation properties prevent temperature fluctuations and hotspots, ensuring uniform heat distribution throughout the treatment process. This stability is crucial for achieving consistent and high-quality results in heat treatment applications. In conclusion, insulating fire bricks are essential in improving the efficiency of heat treatment processes. Their low thermal conductivity, ability to minimize heat loss, and capacity to withstand high temperatures contribute to reduced energy consumption, faster heating times, and improved temperature control. By incorporating these bricks, heat treatment operations can achieve higher efficiency, lower costs, and more consistent results.

- Q: Is it necessary to use mortar when installing insulating fire bricks?

- Yes, it is necessary to use mortar when installing insulating fire bricks. Mortar is a crucial component in the installation process as it helps to bond the bricks together, ensuring a tight and secure fit. It also helps to create a strong and durable structure that can withstand high temperatures. Without mortar, the bricks may not be properly secured and could shift or become loose, compromising the integrity of the installation. Additionally, mortar helps to fill in any gaps or spaces between the bricks, providing insulation and preventing heat loss. Therefore, using mortar is essential for a successful and effective installation of insulating fire bricks.

- Q: Are insulating fire bricks resistant to chemical attack?

- Yes, insulating fire bricks are generally resistant to chemical attack. These bricks are made from high-purity refractory materials, such as alumina or silica, which have excellent chemical stability. They are designed to withstand high temperatures and are thus highly resistant to the corrosive effects of chemicals. However, it is important to note that the degree of chemical resistance can vary depending on the specific composition of the insulating fire brick and the type of chemical being used. In some cases, certain aggressive chemicals may still cause some degree of degradation or erosion over time. Therefore, it is always recommended to consult the manufacturer or supplier for specific information regarding the chemical resistance of insulating fire bricks in relation to the intended application.

- Q: Can insulating fire bricks be used in chimneys?

- Insulating fire bricks are indeed suitable for chimneys. Their purpose lies in enduring high temperatures, rendering them an excellent option for lining chimneys. Not only do they possess superb thermal insulation properties, thus minimizing heat loss and enhancing chimney efficiency, but they are also lightweight and simple to install. Nonetheless, it is crucial to acknowledge that insulating fire bricks may not be suitable for every chimney type. To ascertain the appropriate materials for your individual chimney requirements, consulting a professional or chimney specialist is highly recommended.

- Q: Do insulating fire bricks require special installation techniques?

- Special installation techniques are not necessarily required for insulating fire bricks, although there are certain factors to consider during the installation process. These bricks are designed to withstand high temperatures and provide thermal insulation, making them perfect for lining fireplaces, kilns, furnaces, and other applications that involve high temperatures. Although the installation process may differ depending on the specific application, there are general guidelines to follow. First and foremost, it is crucial to ensure that the surface where the bricks will be installed is clean and free from debris. This will assist in proper adhesion of the bricks and guarantee a secure installation. It is advisable to use a high-temperature refractory mortar or adhesive to bond the bricks together and to the surface. This mortar should be specifically formulated for high-temperature applications to ensure durability and heat resistance. It is essential to adhere to the manufacturer's instructions for mixing and applying the mortar. To maximize the insulating properties of the bricks, it is vital to achieve proper alignment and tight joints during the installation process. This can be accomplished by using a level and a rubber mallet to carefully position the bricks, ensuring they are evenly and tightly placed. Furthermore, it is important to account for the expansion and contraction of the bricks caused by the high temperatures they will be exposed to. This can be accomplished by leaving small gaps between the bricks and using expansion joints or flexible materials in areas where movement is anticipated. Finally, it is recommended to consult the manufacturer's guidelines and recommendations for specific installation techniques and considerations. Different types of insulating fire bricks may have slightly different requirements, so it is important to follow the instructions provided by the manufacturer. In conclusion, while insulating fire bricks do not demand complex installation techniques, it is crucial to pay attention to details and adhere to the recommended guidelines to ensure a successful and long-lasting installation.

- Q: What is the typical porosity of an insulating fire brick?

- The typical porosity of an insulating fire brick is around 40% to 60%.

- Q: Are insulating fire bricks resistant to alkali attack?

- Yes, insulating fire bricks are generally resistant to alkali attack. These bricks are made from high-temperature refractory materials and are designed to withstand extreme temperatures and chemical environments. Alkalis are known to corrode and degrade certain materials, but insulating fire bricks are specifically formulated to resist this type of chemical attack. They have a low porosity and dense structure, which helps prevent the penetration of alkalis into the brick's surface. Additionally, the refractory materials used in these bricks have a high melting point and are chemically inert, making them well-suited for applications where alkali exposure is a concern. However, it is important to note that the specific resistance of insulating fire bricks to alkali attack may vary depending on the composition and manufacturing process of the brick, as well as the concentration and duration of alkali exposure. Therefore, it is always recommended to consult with the manufacturer or supplier for detailed information about the resistance of their specific insulating fire bricks to alkali attack.

- Q: Are insulating fire bricks suitable for use in ceramic fiber modules?

- Insulating fire bricks should not be used in ceramic fiber modules. These two materials are composed of different substances and possess distinct characteristics. Insulating fire bricks are typically crafted from dense refractory materials like clay or alumina, which grant them exceptional thermal insulation properties. Conversely, ceramic fiber modules are constructed with lightweight ceramic fibers and are intended for insulation and heat containment in high-temperature settings. They exhibit remarkable resistance to thermal shock and can withstand sudden temperature fluctuations. Employing insulating fire bricks in ceramic fiber modules would not yield the same insulation and heat containment capabilities as using proper ceramic fiber modules. This may result in inadequate performance and reduced efficiency when subjected to high temperatures. Consequently, it is crucial to utilize appropriate materials for specific applications in order to ensure optimal performance and safety.

- Q: Are insulating fire bricks suitable for use in heat exchangers?

- Depending on the specific requirements and conditions of the heat exchanger application, insulating fire bricks can be considered as a suitable option. These bricks possess exceptional thermal insulation properties, low thermal conductivity, and a remarkable ability to withstand high temperatures. As a result, they effectively minimize heat loss and conserve energy within heat exchanger systems. Moreover, insulating fire bricks are lightweight and possess good mechanical strength, allowing for convenient installation and maintenance. They are also resistant to thermal shock and chemical corrosion, guaranteeing durability and longevity even in harsh operating environments. Nevertheless, it is important to acknowledge that insulating fire bricks may not be appropriate for all heat exchanger applications. In instances where efficient heat transfer necessitates high thermal conductivity, alternative materials with greater thermal conductivity should be taken into consideration, particularly in certain industrial heat exchangers. Ultimately, the suitability of insulating fire bricks in heat exchangers relies on specific factors such as the operating conditions, design requirements, and performance expectations of the system. Therefore, it is advisable to consult experts or engineers well-versed in heat exchanger design and materials to determine the most suitable choice for a particular application.

Send your message to us

Insulating Fire Brick - High Quality Clay Refractory Insulating Fire Brick for Industrial Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords