Insulating Fire Brick - GJM32

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 pcs pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick GJM32

Insulating fire brick GJM32 temperature is 1760℃(3200℉). We could supply a wide range of shapes. To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM32,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

Characteristics of Insulating Fire Brick GJM32

Our insulating bricks GJM32 exhibit the following characteristics:

High refractoriness temperature

Strong resistance to slag

Good high temperature properties

Typical Application of Insulating Fire Brick GJM32

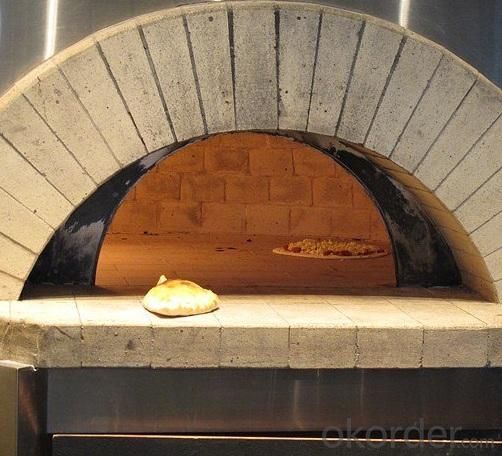

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, high temperature kiln, calcined lime furnace, regenerator in glass furnace.

Technical Data of Insulating Fire Brick GJM32

|

| GJM32 |

Physical Properties: |

|

|

Classifiction Temperature | ℃ | 1650 |

Density | Kg/m3 | 1100 |

Cold Crushing Strength | Mpa | 3.5 |

Reheating Linear Change(24hrs) |

|

|

1650℃ | % | 0.8 |

Hot Load Strength Deform(90 minutes) |

|

|

1370℃ at 0.069 Mpa(10psi) | % | 0.1 |

Thermal Conductivity |

|

|

400℃ | W/m.k | 0.32 |

600℃ | W/m.k | 0.35 |

800℃ | W/m.k | 0.38 |

1000℃ | W/m.k | 0.42 |

1200℃ | W/m.k | 0.44 |

Specific Heat | KJ/Kg.K | 1.10 |

Chemical Analysis: |

|

|

Al2O3 | % | 75.0 |

SiO2 | % | 23.2 |

Fe2O3 | % | 0.5 |

TiO2 | % | 0.1 |

CaO | % | 0.1 |

MgO | % | 0.1 |

Na2O+K2O | % | 0.6 |

CNBM has success in insulating fire bricks due to their cost-effectiveness, excellent insulation performance and high temperature properties. CNBM also has experience in magnesia brick application and would like to assist you in product selection, system design, and installation techniques.

- Q: Can insulating fire bricks be used as a lining for boilers?

- Indeed, boilers can make use of insulating fire bricks as linings. These bricks are specifically engineered to endure extreme temperatures and possess outstanding thermal insulation capabilities. Their prevalent application lies in contexts where conserving heat and promoting energy efficiency are paramount, notably in industrial boiler settings. The insulating properties inherent in these bricks facilitate the reduction of heat dissipation and enhance the overall efficiency of the boiler. Furthermore, their robustness and ability to withstand thermal shock render them fitting for deployment within boiler linings, where they can endure the harshest conditions and temperature fluctuations.

- Q: Are insulating fire bricks resistant to thermal stress?

- Yes, insulating fire bricks are resistant to thermal stress. These bricks are specially manufactured to withstand high temperatures and thermal fluctuations without cracking or breaking. They are made from refractory materials that have excellent thermal insulation properties and can handle extreme heat conditions. Insulating fire bricks have low thermal conductivity, meaning they can effectively resist heat transfer and maintain their structural integrity even when exposed to rapid temperature changes. They are commonly used in applications such as kilns, furnaces, and fireplaces, where thermal stress is a significant concern. Overall, insulating fire bricks are designed to provide reliable and durable insulation while withstanding the thermal stress associated with high-temperature environments.

- Q: What is the price of thermal insulation brick for exterior wall?

- But also depends on how your drawings are made, so as to quote a specific price. There is also the price of each place is not the same, so the quotation will be different.

- Q: Can insulating fire bricks be used in the construction of pottery kiln shelves?

- Indeed, pottery kiln shelves can be constructed using insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures while offering exceptional insulation, rendering them an optimal choice for kiln shelves. Their utilization aids in maintaining a uniform dispersion of heat and averting thermal shock, a critical aspect in the pottery firing process. Moreover, the lightweight and manageable nature of insulating fire bricks make them a pragmatic option for the construction of kiln shelves.

- Q: Can insulating fire bricks be used for insulation in hot water tanks?

- Yes, insulating fire bricks can be used for insulation in hot water tanks. These bricks have high heat resistance properties and can effectively trap and retain heat, making them suitable for insulating hot water tanks and improving their energy efficiency.

- Q: Are insulating fire bricks resistant to vibration or seismic activity?

- Insulating fire bricks are generally not resistant to vibration or seismic activity. These bricks are designed to provide insulation and are therefore lightweight and porous. While they may be able to withstand minor vibrations or low levels of seismic activity, they are not specifically engineered to handle significant levels of shaking or tremors. In applications where vibration or seismic activity is a concern, it is advisable to use specially designed bricks or materials that are specifically manufactured to withstand these types of forces.

- Q: Can insulating fire bricks be used in ceramic fiber blankets?

- It is not possible to use insulating fire bricks in ceramic fiber blankets. Insulating fire bricks are dense and solid, specifically designed to offer insulation and endure high temperatures in settings like furnaces and kilns. Conversely, ceramic fiber blankets are flexible and lightweight, consisting of ceramic fibers that provide exceptional thermal insulation. They are frequently utilized as insulation in diverse industrial applications, such as lining for furnaces, boilers, and high-temperature equipment. Combining insulating fire bricks with ceramic fiber blankets would not yield effective results because these materials possess distinct properties and serve different purposes.

- Q: Can insulating fire bricks be used in DIY projects?

- Yes, insulating fire bricks can be used in DIY projects. They are commonly used in various DIY applications such as constructing fire pits, ovens, kilns, and for lining chimneys. These bricks have excellent insulation properties, can withstand high temperatures, and are easy to work with, making them ideal for DIY projects requiring heat resistance.

- Q: Can insulating fire bricks be used in the construction of glassware molds?

- Insulating fire bricks are indeed applicable for the construction of glassware molds due to their exceptional insulation properties. These bricks, crafted from lightweight materials, possess excellent insulation capabilities, rendering them suitable for deployment in high-temperature scenarios like glassware molds. They can withstand the extreme heat generated during the glass molding process and contribute to maintaining a steady temperature within the mold. Moreover, these bricks exhibit low thermal conductivity, which prevents excessive heat dissipation and ensures efficient energy utilization. All in all, by incorporating insulating fire bricks into the construction of glassware molds, one can achieve superior heat retention, enhanced thermal efficiency, and improved mold stability, ultimately leading to the production of higher quality glass products.

- Q: Are insulating fire bricks suitable for insulation in power boilers?

- Insulating fire bricks can be suitable for insulation in power boilers depending on the specific requirements and conditions of the boiler. Insulating fire bricks are known for their high temperature resistance and low thermal conductivity, which makes them effective in reducing heat loss and improving energy efficiency in various applications. However, when considering their use in power boilers, several factors need to be taken into account. Firstly, the operating temperature and pressure of the boiler should be considered to ensure that the insulating fire bricks can withstand these conditions without any degradation or failure. Power boilers typically operate at high temperatures and pressures, so it is important to choose insulating fire bricks that have a high temperature rating and can withstand the required pressure. Additionally, the composition and structure of the insulating fire bricks should be considered. Some power boilers may contain corrosive or abrasive substances, which can potentially damage the insulating fire bricks over time. Therefore, it is important to select insulating fire bricks that are resistant to corrosion and abrasion, or to consider additional protective measures such as coatings or linings. Furthermore, the thermal conductivity of the insulating fire bricks should be evaluated. While insulating fire bricks have low thermal conductivity compared to other refractory materials, it is important to ensure that they provide sufficient insulation for the specific requirements of the power boiler. This may involve calculating heat transfer rates and determining the appropriate thickness and density of the insulating fire bricks to achieve the desired insulation performance. Ultimately, the suitability of insulating fire bricks for insulation in power boilers depends on careful consideration of factors such as temperature, pressure, composition, structure, and thermal conductivity. Engaging with experts and conducting proper evaluations and calculations will help determine if insulating fire bricks are a suitable choice for insulation in a particular power boiler application.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 10.00% Northern Europe 30.00% North America 30.00% Eastern Asia 5.00% Africa 10.00% Southeast Asia 15.00% Western Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 10 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 16,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Insulating Fire Brick - GJM32

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 pcs pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords