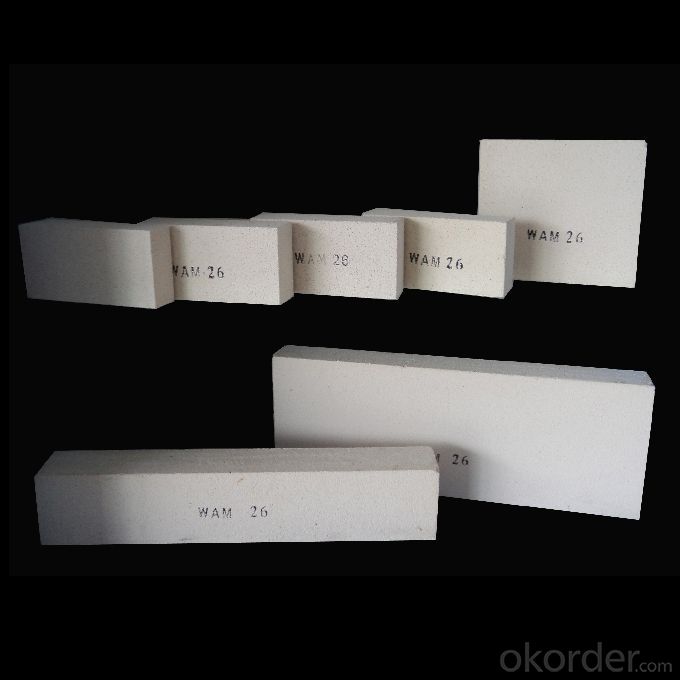

Insulating Fire Brick - Refractory Mullite GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: How do insulating fire bricks affect energy efficiency?

- Insulating fire bricks play a crucial role in improving energy efficiency in various applications. These bricks are designed to have low thermal conductivity, which means they are efficient in minimizing heat transfer. By reducing the amount of heat that escapes or enters a system, insulating fire bricks help to conserve energy and maintain optimal temperature levels. In industrial furnaces and kilns, insulating fire bricks act as a barrier, preventing heat from dissipating into the surrounding environment. This leads to reduced energy consumption as the heat is retained within the system, allowing for more efficient and cost-effective operation. Additionally, insulating fire bricks can help to reduce the time required for the system to reach and maintain the desired temperature, further enhancing energy efficiency. In residential and commercial buildings, insulating fire bricks are used in the construction of fireplaces, stoves, and chimneys. These bricks effectively trap heat within the combustion chamber, preventing it from escaping through the walls. As a result, the heat generated by the fire is utilized more efficiently, reducing the need for additional heating sources and ultimately saving energy. Furthermore, insulating fire bricks are also employed in the insulation of pipelines, boilers, and other equipment that require thermal protection. By reducing heat transfer through these components, energy losses are minimized, leading to improved energy efficiency. Overall, insulating fire bricks play a significant role in enhancing energy efficiency by minimizing heat loss, maximizing heat retention, and optimizing temperature control in various applications. Their low thermal conductivity properties make them an essential component in systems where energy conservation and cost-effectiveness are crucial considerations.

- Q: Are insulating fire bricks suitable for outdoor applications?

- Insulating fire bricks are generally not suitable for outdoor applications. These bricks are designed to be used in high-temperature environments such as kilns, furnaces, and other industrial applications. They have excellent thermal insulation properties and can withstand very high temperatures. However, insulating fire bricks are not designed to withstand exposure to the elements and can be easily damaged by moisture, rain, and extreme weather conditions. They are not resistant to freezing and thawing cycles, which can cause them to crack and break. For outdoor applications, it is recommended to use fire bricks that are specifically made for outdoor use. These bricks are usually made of dense clay or other materials that can withstand moisture and weather conditions. They are more durable and can provide better protection against the elements. It is important to consider the specific requirements and conditions of your outdoor application before choosing the appropriate type of fire bricks. Consulting with a professional or supplier knowledgeable in fire bricks can help ensure that you select the right product for your needs.

- Q: Can insulating fire bricks be used as a refractory material?

- Insulating fire bricks can indeed serve as a refractory material, given their specific design for enduring high temperatures and thermal shock. These bricks prove suitable for situations necessitating heat insulation and refractory properties. By virtue of their low thermal conductivity, they effectively diminish heat loss and conserve energy. Industries such as steel, glass, ceramics, and petrochemicals frequently employ insulating fire bricks as lining materials within furnaces, kilns, ovens, and other equipment operating at elevated temperatures. The combination of their capacity to withstand extreme temperatures and insulating characteristics renders them an outstanding option for refractory applications.

- Q: Can insulating fire bricks be used for insulation in gas furnaces?

- Yes, insulating fire bricks can be used for insulation in gas furnaces. They are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in gas furnaces to improve energy efficiency and enhance overall performance.

- Q: Is it possible to paint or coat insulating fire bricks?

- Indeed, it is feasible to apply paint or coat insulating fire bricks. Nevertheless, it is imperative to utilize a type of paint or coating that can endure elevated temperatures, given that insulating fire bricks are intended for usage in exceedingly hot surroundings. Ordinary paint or coatings may not be appropriate since they can combust or deteriorate under high temperatures. It is advisable to employ specialized high temperature paint or coatings that have been specifically formulated to withstand the intense heat of insulating fire bricks. Typically, these types of paint or coatings possess a resistance to high temperatures of several hundred degrees Celsius or greater. Moreover, it is crucial to adequately clean and prepare the surface of the bricks prior to applying any paint or coating to ensure optimal adhesion and durability.

- Q: Can insulating fire bricks be used in paper mills?

- Insulating fire bricks are indeed applicable for use in paper mills. They are widely employed in various industries that necessitate effective insulation against elevated temperatures, including steel, glass, and ceramics. Within paper mills, where activities like drying, heating, and burning take place, insulating fire bricks offer an ideal solution for lining kilns, furnaces, and other equipment. Their exceptional thermal insulation properties and ability to withstand extreme temperatures render them highly suitable for deployment in paper mills, where heat plays an indispensable role in the manufacturing process. Furthermore, these bricks possess the advantages of being lightweight and exhibiting low thermal conductivity, enabling efficient heat retention and yielding energy savings.

- Q: Are insulating fire bricks resistant to abrasion or erosion?

- Insulating fire bricks are generally not resistant to abrasion or erosion. While they are excellent at insulating heat, they are typically made from materials that are not designed to withstand high levels of wear and tear. Insulating fire bricks are often used in applications where they are not exposed to significant mechanical forces or abrasive materials. If abrasion or erosion is a concern, a different type of refractory material or lining may be more suitable for the specific application.

- Q: Are insulating fire bricks resistant to sound transmission?

- Insulating fire bricks, also known as refractory bricks, are primarily designed to withstand high temperatures and provide thermal insulation. While they are effective in reducing heat transfer, they are not specifically designed to resist sound transmission. Insulating fire bricks are made from materials such as clay, alumina, and silica, which are chosen for their ability to withstand high temperatures. These materials are dense and have a low porosity, which helps to prevent heat from passing through the bricks. However, sound waves can easily pass through solid materials, including insulating fire bricks, unless additional measures are taken to reduce sound transmission. To effectively reduce sound transmission, other soundproofing methods should be used in conjunction with insulating fire bricks. These can include adding additional layers of acoustic insulation or using sound barriers such as mass-loaded vinyl or acoustic panels. In summary, while insulating fire bricks are excellent for thermal insulation, they are not inherently resistant to sound transmission. Additional soundproofing measures should be taken to effectively reduce noise transmission in a given space.

- Q: Can insulating fire bricks be used for insulation in hot water tanks?

- Yes, insulating fire bricks can be used for insulation in hot water tanks. Insulating fire bricks are designed to have excellent thermal insulation properties, making them an ideal choice for insulating hot water tanks. These bricks can effectively prevent heat loss from the hot water tank, helping to maintain the temperature of the water for longer periods of time. Additionally, insulating fire bricks are highly durable and can withstand high temperatures without cracking or breaking, making them a reliable choice for hot water tank insulation.

- Q: Can insulating fire bricks be used in both residential and industrial applications?

- Yes, insulating fire bricks can be used in both residential and industrial applications. They are commonly used in residential fireplaces and wood-burning stoves for their insulating properties, as well as in industrial furnaces, kilns, and ovens to retain heat and improve energy efficiency.

Send your message to us

Insulating Fire Brick - Refractory Mullite GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords