Insulating Fire Brick - Refractory Mullite GJM30

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

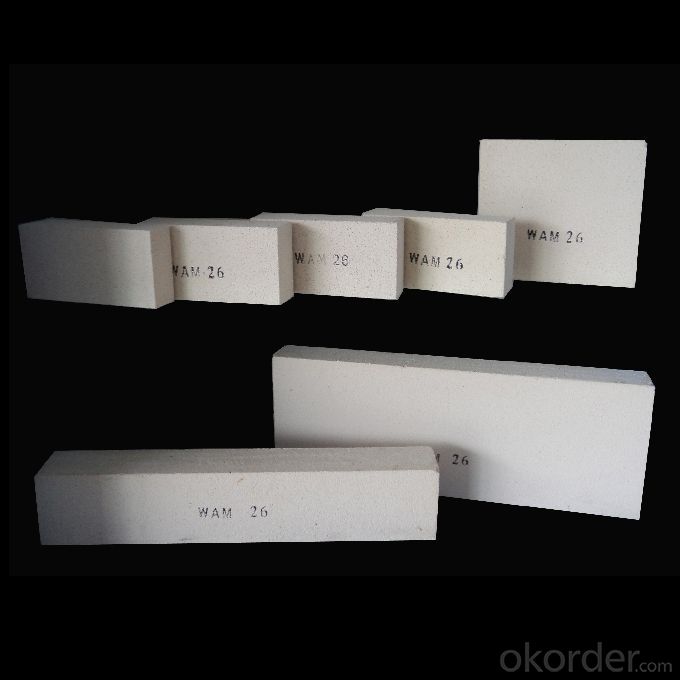

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Are insulating fire bricks easy to cut or shape?

- Compared to other bricks, insulating fire bricks offer a relatively simple cutting and shaping process. This is mainly because of their lower density and composition, enabling easier manipulation using standard masonry tools. However, it is crucial to acknowledge that the level of simplicity can differ depending on the specific type and brand of insulating fire brick. Some may demand special tools or techniques for cutting or shaping, while others may be more user-friendly. To ensure accurate cutting or shaping techniques, it is always advisable to refer to the manufacturer's instructions or seek professional guidance when working with insulating fire bricks.

- Q: Can insulating fire bricks be used for insulation in power boiler walls?

- Yes, insulating fire bricks can be used for insulation in power boiler walls. Insulating fire bricks are designed to provide excellent thermal insulation, high temperature resistance, and low thermal conductivity. These properties make them suitable for use in power boiler walls, where insulation is crucial to reduce heat loss and improve energy efficiency.

- Q: Are insulating fire bricks resistant to impact or mechanical stress?

- Yes, insulating fire bricks are resistant to impact and mechanical stress. Insulating fire bricks are made from lightweight refractory materials that are designed to withstand high temperatures and thermal shock. These bricks are specifically engineered to have a high resistance to mechanical stress and impact, making them suitable for various applications where they may be subjected to external forces or pressure. Their structural integrity and durability allow them to maintain their shape and thermal insulation properties even when exposed to mechanical stress or impact, making them an ideal choice for use in furnaces, kilns, and other high-temperature environments.

- Q: Are insulating fire bricks easy to cut and shape?

- Indeed, cutting and shaping insulating fire bricks proves to be relatively simple. These bricks consist of lightweight refractory materials like ceramic fibers, enabling them to be more manageable when compared to traditional fire bricks. Common tools such as saws, knives, or chisels can be employed to cut and shape these insulating fire bricks. Due to their lightweight composition, they can be easily maneuvered and positioned, facilitating more accurate cuts and shapes. Moreover, if necessary, openings or specific designs can be effortlessly drilled or carved into these bricks. Overall, the convenience of cutting and shaping insulating fire bricks makes them an ideal choice for various applications in construction, insulation, and fireproofing.

- Q: Can insulating fire bricks be used in the construction of hearths?

- Yes, insulating fire bricks can be used in the construction of hearths. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in hearth construction. They help to retain heat and prevent the loss of energy, ensuring efficient and effective heating.

- Q: How do insulating fire bricks compare to other insulation materials like ceramic fiber?

- Insulating fire bricks and ceramic fiber are both commonly used as insulation materials, but they have some key differences in terms of their properties and applications. Insulating fire bricks, also known as refractory bricks, are dense and solid bricks made from various refractory materials like clay, alumina, and silica. They are highly durable and offer excellent thermal conductivity and resistance to high temperatures. Insulating fire bricks are commonly used in industrial furnaces, kilns, and fireplaces to provide insulation and retain heat. On the other hand, ceramic fiber is a lightweight and flexible insulation material made from a blend of alumina-silica and other refractory materials. It is available in various forms like blankets, boards, and modules, which can be easily cut and shaped for insulation purposes. Ceramic fiber offers excellent thermal resistance, low thermal conductivity, and is commonly used in applications where flexibility and ease of installation are important, such as boilers, ovens, and piping systems. In terms of thermal insulation properties, both insulating fire bricks and ceramic fiber have high heat resistance and low thermal conductivity, which allows them to effectively prevent heat transfer and retain heat. However, insulating fire bricks have a higher density and solidity, which makes them more durable and better suited for heavy-duty applications where mechanical strength is required. Ceramic fiber, on the other hand, is more lightweight and flexible, offering easier installation and better thermal shock resistance. Cost-wise, insulating fire bricks tend to be more expensive compared to ceramic fiber, mainly due to the difference in manufacturing processes and materials used. Insulating fire bricks require high-temperature firing and are made from higher-cost raw materials, while ceramic fiber is produced through a melt-spinning process, making it more cost-effective. Overall, the choice between insulating fire bricks and ceramic fiber depends on the specific requirements of the application. Insulating fire bricks are ideal for heavy-duty and high-temperature applications that require durability and mechanical strength, while ceramic fiber is more suitable for applications that demand flexibility, ease of installation, and resistance to thermal shock.

- Q: Is it possible to repair damaged insulating fire bricks?

- Yes, it is possible to repair damaged insulating fire bricks. The damaged bricks can be repaired by using refractory cement or mortar to fill in cracks or gaps. Additionally, damaged portions can be cut out and replaced with new bricks. However, the extent of the damage and the specific repair method required may vary depending on the severity of the damage.

- Q: What is the typical bulk density of an insulating fire brick?

- The typical bulk density of an insulating fire brick is around 0.6 to 1.2 grams per cubic centimeter (g/cm³).

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Insulating fire bricks can indeed be used in high-temperature ducts. These bricks are specially designed to withstand extreme temperatures, making them an ideal choice for applications where heat retention and insulation are crucial. With their low thermal conductivity and high resistance to thermal shock, insulating fire bricks can effectively trap heat within the ducts, preventing any loss of energy and ensuring efficient heat transfer. Additionally, their lightweight nature makes them easy to install and handle, while their durability allows them to withstand the harsh conditions of high-temperature environments. Overall, insulating fire bricks are a reliable and effective solution for insulating high-temperature ducts.

- Q: Can insulating fire bricks be used in fertilizer plants?

- Yes, insulating fire bricks can be used in fertilizer plants. They are commonly used in high-temperature applications, such as kilns and furnaces, to provide thermal insulation and protect against heat loss. In fertilizer plants, where various processes involve high temperatures, insulating fire bricks can be utilized to enhance energy efficiency and maintain optimal temperature conditions.

Send your message to us

Insulating Fire Brick - Refractory Mullite GJM30

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords