Insulating Fire Brick - Refractory Mullite GJM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKORDER Series Insulating Bricks

OKORDER series insulating bricks are a kind of highly efficient, energy saving, low-carbon, environmental protection advanced products which are manufactured according to ASTM standard. OKORDER series products are the best lining and insulation materials in all types of industrial furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass. They can be applied as heat insulation or no-melt erosion parts of the working layer. The products have been widely used in the following furnaces and achieved satisfactory results.

Application of Insulating Bricks

Metallurgy industry: Blast furnace, Hot blast stove, Reheating furnace, etc.

Petrochemical industry: Ethylene cracking furnace, Hydrogen production furnace, Primary reformer furnace, Reheating furnace, etc.

Ceramics Industry: Roller kiln, Pusher kiln, etc.

Glass industry: Glass furnace regenerator, etc.

Carbon Industry: Carbon roaster, etc.

Aluminum electrolytic industry: aluminum reduction cells,etc.

Other industries: Tunnel kiln, Shuttle kiln, etc.

Advantages of Insulating Bricks

Low Thermal Conductivity: More porosity brings excellent insulation effect, energy saving.

High Crushing Strength: High crushing strength under thermal state, volume stability.

Low Heat Storage: Little thermal storage when absorb more heat, energy saving effect is obvious.

High Purity: Low content of iron, alkaline and metal impurities.

Accurate Dimension: Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

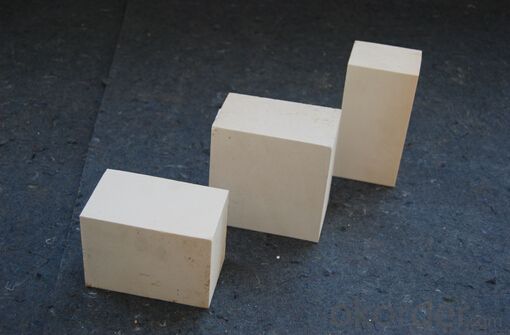

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Are insulating fire bricks resistant to flame spread?

- Insulating fire bricks exhibit exceptional resistance against flame propagation. Crafted with utmost precision, these bricks are tailored to endure extreme temperatures while effectively trapping and insulating heat. Constructed from refractory materials with minimal thermal conductivity, they possess remarkable capabilities in impeding heat transfer and thwarting the spread of flames. Widely employed in kilns, furnaces, and fireplaces, where maintaining and managing high temperatures is of paramount importance, these bricks' flame-resistant properties render them an unwavering and secure choice for such environments.

- Q: Are insulating fire bricks resistant to thermal stress?

- Insulating fire bricks have the ability to resist thermal stress. These bricks are specifically designed to endure high temperatures and fluctuations without cracking or breaking. They are constructed from refractory materials that possess exceptional thermal insulation properties and can tolerate extreme heat. Insulating fire bricks possess a low thermal conductivity, allowing them to effectively resist heat transfer and maintain their structural integrity even when exposed to rapid temperature changes. They find common applications in kilns, furnaces, and fireplaces, where thermal stress is a major concern. In essence, insulating fire bricks are engineered to offer dependable and long-lasting insulation while enduring the thermal stress associated with high-temperature environments.

- Q: Can insulating fire bricks be used for insulation in residential walls?

- Insulating fire bricks are primarily designed for high-temperature applications, such as in kilns or furnaces. While they do provide excellent insulation properties, they are not typically recommended for use in residential walls. The reason is that insulating fire bricks may not meet the specific building codes and regulations required for residential construction. Additionally, there are other insulation materials available that are better suited for residential walls, such as fiberglass or foam insulation, which are more cost-effective and easier to install.

- Q: Can insulating fire bricks be used for insulation in hot blast stoves?

- Yes, insulating fire bricks can be used for insulation in hot blast stoves. Insulating fire bricks are designed to withstand high temperatures and have excellent thermal insulation properties. They are made from lightweight materials with low thermal conductivity, which allows them to effectively retain heat and prevent heat transfer to the surrounding environment. In hot blast stoves, where temperatures can reach extremely high levels, insulating fire bricks can help maintain high temperatures inside the stove while minimizing heat loss. This not only improves the energy efficiency of the stove but also helps to protect the structure from excessive heat. Therefore, using insulating fire bricks for insulation in hot blast stoves is a common and effective practice.

- Q: Can insulating fire bricks be used in the construction of metal smelting molds?

- Yes, insulating fire bricks can be used in the construction of metal smelting molds. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in smelting processes where extreme heat is required. These bricks have excellent thermal insulation properties, which help to retain the heat and minimize heat loss during the smelting process. This is important for maintaining a consistent temperature within the mold, ensuring efficient and successful metal smelting. Additionally, insulating fire bricks are lightweight and easy to handle, making them a practical choice for constructing molds. Overall, insulating fire bricks are a reliable and effective option for constructing metal smelting molds.

- Q: Can insulating fire bricks be used in the construction of glass melting tanks?

- Yes, insulating fire bricks can be used in the construction of glass melting tanks. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. This makes them ideal for use in glass melting tanks, where extreme temperatures are required to melt the glass. The insulating properties of these bricks help to minimize heat loss and maintain the desired temperature within the tank, resulting in more efficient and cost-effective glass melting processes. Additionally, insulating fire bricks are durable and resistant to thermal shock, making them a reliable choice for the construction of glass melting tanks.

- Q: Is it possible to cut insulating fire bricks to fit custom shapes?

- Cutting insulating fire bricks to fit custom shapes is indeed possible. These bricks, composed of lightweight materials like ceramic fiber, can be easily cut or shaped using a range of tools. Cutting methods typically involve a saw, knife, or even a hot wire cutter. However, it is crucial to prioritize safety precautions and wear protective gear while undertaking this task. Dust and sharp edges may be produced during the cutting process. By employing suitable tools and techniques, it becomes achievable to tailor insulating fire bricks to any desired custom shape.

- Q: How do insulating fire bricks affect the overall noise reduction of a structure?

- Insulating fire bricks can significantly contribute to the overall noise reduction of a structure. These bricks have excellent sound-absorbing properties, which help in reducing the transmission of sound waves through the walls or partitions. By effectively dampening and absorbing sound vibrations, insulating fire bricks can minimize the noise pollution within a structure, creating a quieter and more peaceful environment.

- Q: Can insulating fire bricks be used for insulation in heat treatment furnaces?

- Indeed, insulation in heat treatment furnaces can be achieved through the utilization of insulating fire bricks. These bricks are specially engineered to endure extreme temperatures and offer exceptional thermal insulation properties. With their low thermal conductivity, they effectively trap heat within the furnace. Moreover, their lightweight composition facilitates effortless handling and installation. Insulating fire bricks find widespread application in diverse heat treatment procedures, including annealing, tempering, and hardening, guaranteeing utmost heat retention and energy efficiency within the furnace.

- Q: Can insulating fire bricks be used in the construction of crucible furnaces?

- Yes, insulating fire bricks can be used in the construction of crucible furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in crucible furnaces. These bricks are made from lightweight materials such as alumina and silica, which have low thermal conductivity and can effectively retain heat. By using insulating fire bricks, the crucible furnace can achieve higher energy efficiency, faster heating times, and better temperature control. Additionally, these bricks are also resistant to thermal shock, ensuring they can withstand the intense heat generated in the crucible furnace. Overall, insulating fire bricks are a popular choice for constructing crucible furnaces due to their excellent thermal insulation properties and ability to withstand high temperatures.

Send your message to us

Insulating Fire Brick - Refractory Mullite GJM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords