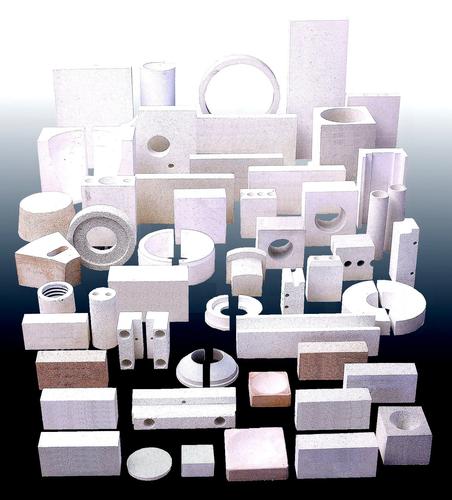

Insulating Fire Brick - High-Quality Insulation for Fire Safety

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: Can insulating fire bricks be used in the construction of rotary kilns?

- Yes, insulating fire bricks can be used in the construction of rotary kilns. Insulating fire bricks are designed to provide high thermal insulation, making them ideal for applications where heat retention is important. In the construction of rotary kilns, insulating fire bricks can be used as a lining material to minimize heat loss from the kiln and improve its energy efficiency. Additionally, these bricks have good resistance to thermal shock, which is crucial in the high-temperature environment of a rotary kiln. Overall, using insulating fire bricks in the construction of rotary kilns can help enhance their performance and reduce energy consumption.

- Q: Can insulating fire bricks be used in the construction of heat shields?

- Certainly, heat shields can indeed be constructed using insulating fire bricks. These bricks are specifically designed to withstand elevated temperatures and possess exceptional thermal insulation properties. Their ability to effectively absorb and distribute heat makes them an ideal choice for the creation of heat shields, which serve to safeguard against excessive heat and mitigate thermal damage. In industries that involve high temperatures, such as steel, glass, and ceramics, insulating fire bricks are frequently employed. Moreover, their lightweight nature and ease of handling make them a practical option for constructing portable or easily installable heat shields. In summary, insulating fire bricks are a reliable and appropriate material for constructing heat shields in a diverse range of applications.

- Q: Are insulating fire bricks safe to use in contact with food or beverages?

- Using insulating fire bricks in direct contact with food or beverages is not recommended due to safety concerns. These bricks, typically composed of materials like silica and alumina, are primarily used for their ability to withstand high temperatures and provide efficient insulation. While they are commonly utilized in industrial settings like kilns and furnaces, their suitability for food preparation or consumption is limited. When exposed to high temperatures, insulating fire bricks can release harmful substances, especially if they have not been properly cured or if they come into direct contact with food or beverages. These substances may include small amounts of heavy metals or other toxic compounds, which can pose health risks if consumed. To ensure the safety of food and beverages, it is advisable to opt for materials specifically designed for contact with food, such as food-grade stainless steel, glass, or ceramic. These materials are non-reactive and do not release any harmful substances when exposed to high temperatures. It is vital to prioritize the health and well-being of individuals by using appropriate materials for food and beverage preparation.

- Q: Can insulating fire bricks be used for insulation in cement kilns?

- Insulation in cement kilns can be achieved by using insulating fire bricks. These bricks are made from lightweight materials like ceramic fibers or expanded clay, which possess high insulation properties. Their low thermal conductivity allows them to effectively reduce heat transfer and retain heat within the kiln. Cement kilns operate at extremely high temperatures, often surpassing 1,400 degrees Celsius (2,500 degrees Fahrenheit). Incorporating insulating fire bricks in the kiln helps prevent heat loss, enhances energy efficiency, and reduces fuel consumption. By creating a barrier between the hot gases inside the kiln and the surrounding environment, these bricks minimize heat escape. Additionally, insulating fire bricks exhibit remarkable resistance to thermal shocks, enabling them to withstand the severe temperature fluctuations that occur in cement kilns. This durability ensures long-lasting insulation, minimizing the need for frequent maintenance and replacement. Nevertheless, it is crucial to note that the specific type and composition of insulating fire bricks required for cement kiln insulation may vary depending on factors such as the kiln's design and operating conditions. Consulting with experts or manufacturers specializing in refractory materials is advisable to ensure the correct selection and installation of insulating fire bricks for cement kiln insulation.

- Q: Can insulating fire bricks be used in the construction of pottery kiln shelves?

- Indeed, pottery kiln shelves can be constructed using insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures while offering exceptional insulation, rendering them an optimal choice for kiln shelves. Their utilization aids in maintaining a uniform dispersion of heat and averting thermal shock, a critical aspect in the pottery firing process. Moreover, the lightweight and manageable nature of insulating fire bricks make them a pragmatic option for the construction of kiln shelves.

- Q: What is the typical lifespan of an insulating fire brick?

- The typical lifespan of an insulating fire brick can vary depending on various factors such as the quality of the brick, the temperature it is exposed to, and the frequency of thermal cycling. However, on average, insulating fire bricks can last anywhere from 5 to 20 years.

- Q: Can insulating fire bricks be used in the construction of heat recovery systems?

- Yes, insulating fire bricks can be used in the construction of heat recovery systems. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for applications where heat recovery is a priority.

- Q: Are insulating fire bricks suitable for insulation in gas turbines?

- Yes, insulating fire bricks are suitable for insulation in gas turbines. They have excellent insulating properties and can withstand high temperatures, making them an ideal choice for protecting and insulating the components of gas turbines.

- Q: Are there any safety precautions to consider when using insulating fire bricks?

- Yes, there are safety precautions to consider when using insulating fire bricks. Firstly, it is important to wear appropriate personal protective equipment, such as gloves and safety goggles, to protect against potential injuries. Additionally, due to the high temperatures involved, it is crucial to handle the bricks with care to avoid burns or related accidents. Adequate ventilation should be ensured to prevent the buildup of harmful gases and fumes. Lastly, it is essential to follow the manufacturer's instructions and guidelines for proper installation and usage to minimize any potential risks.

- Q: Can insulating fire bricks be used in high-temperature insulation applications?

- Yes, insulating fire bricks can be used in high-temperature insulation applications. Insulating fire bricks are designed to withstand and retain heat at elevated temperatures. They have low thermal conductivity and high insulation properties, making them ideal for use in applications where high temperatures need to be contained and insulated. These bricks are commonly used in industries such as steel, glass, and ceramics, as well as in furnaces, kilns, and other high-temperature equipment. Insulating fire bricks provide a reliable and efficient solution for insulation in high-temperature environments, helping to maintain heat and reduce energy loss.

Send your message to us

Insulating Fire Brick - High-Quality Insulation for Fire Safety

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords