Insulating Fire Brick - Mullite Refractory Jm 23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKORDER Series Insulating Bricks

OKORDER series insulating bricks are a kind of highly efficient, energy saving, low-carbon, environmental protection advanced products which are manufactured according to ASTM standard. OKORDER series products are the best lining and insulation materials in all types of industrial furnaces in the field of Metallurgy, Aluminum, Petrochemical, Ceramics, Power and Glass. They can be applied as heat insulation or no-melt erosion parts of the working layer. The products have been widely used in the following furnaces and achieved satisfactory results.

Application of Insulating Bricks

Metallurgy industry: Blast furnace, Hot blast stove, Reheating furnace, etc.

Petrochemical industry: Ethylene cracking furnace, Hydrogen production furnace, Primary reformer furnace, Reheating furnace, etc.

Ceramics Industry: Roller kiln, Pusher kiln, etc.

Glass industry: Glass furnace regenerator, etc.

Carbon Industry: Carbon roaster, etc.

Aluminum electrolytic industry: aluminum reduction cells,etc.

Other industries: Tunnel kiln, Shuttle kiln, etc.

Advantages of Insulating Bricks

Low Thermal Conductivity: More porosity brings excellent insulation effect, energy saving.

High Crushing Strength: High crushing strength under thermal state, volume stability.

Low Heat Storage: Little thermal storage when absorb more heat, energy saving effect is obvious.

High Purity: Low content of iron, alkaline and metal impurities.

Accurate Dimension: Precise brick size by machining, cutting and grinding special shapes, expediting bricklaying.

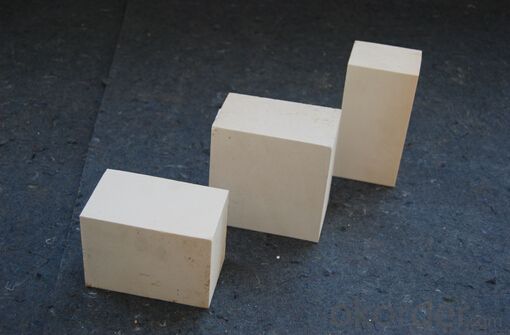

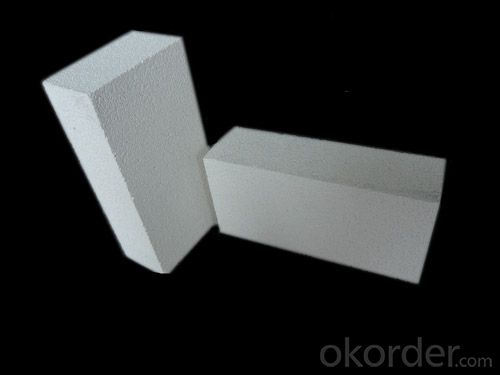

Picture of Insulating Bricks

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Are insulating fire bricks safe to use?

- When used correctly and according to the manufacturer's instructions, insulating fire bricks are generally safe to use. These bricks are specifically designed to endure high temperatures and provide exceptional insulation, making them perfect for applications like lining kilns, furnaces, and fireplaces. Made from lightweight materials like alumina, silica, and other refractory materials, insulating fire bricks aim to minimize heat transfer, thus preventing the escape of heat from the enclosed area. This not only enhances the system's energy efficiency but also reduces the risk of overheating and potential fires, improving safety. To ensure the safe use of insulating fire bricks, it is crucial to install them properly and securely. This involves providing sufficient support and reinforcement to prevent collapse or shifting of the bricks. Additionally, it is essential to use suitable mortar or refractory cement to firmly join the bricks together, creating a sturdy and stable structure. While insulating fire bricks themselves are generally safe, it is important to note that they may contain small amounts of trace elements or materials that can be harmful if released into the environment. Therefore, it is advisable to follow the manufacturer's safety guidelines, which may include wearing protective gloves, goggles, and a dust mask when handling the bricks. In conclusion, insulating fire bricks are a safe and dependable choice for insulation in high-temperature applications. Nevertheless, it is crucial to take necessary precautions during installation and adhere to safety guidelines to ensure their proper and safe use.

- Q: Can insulating fire bricks be used in the construction of lime production ovens?

- Yes, insulating fire bricks can be used in the construction of lime production ovens. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for the intense heat and thermal requirements of lime production ovens. They help maintain consistent temperature levels, reduce heat loss, and improve energy efficiency, making them a reliable choice for such applications.

- Q: Can insulating fire bricks be used in copper smelting furnaces?

- In the realm of copper smelting furnaces, the utilization of insulating fire bricks is indeed possible. These fire bricks have been specifically engineered to endure high temperatures and offer remarkable insulation, rendering them an ideal choice for furnace usage. Composed of materials capable of withstanding the intense heat generated during the smelting process, these bricks are proficient in both retaining and reflecting heat back into the furnace. This aids in the maintenance of the desired temperature and enhances energy efficiency. Moreover, the inclusion of insulating fire bricks can curtail heat loss, thereby resulting in swifter and more efficient copper smelting. For this reason, the incorporation of insulating fire bricks into copper smelting furnaces has become a widespread practice within the industry.

- Q: Can insulating fire bricks be used in refractory lining applications?

- Yes, insulating fire bricks can be used in refractory lining applications. Insulating fire bricks are made from lightweight materials that have high insulating properties, such as clay or silica. These bricks are designed to provide excellent thermal insulation, reducing heat loss and improving energy efficiency in high-temperature applications. In refractory lining applications, insulating fire bricks are commonly used to line the walls, floors, and roofs of furnaces, boilers, kilns, and other industrial equipment. They are effective in preventing heat transfer to the surrounding environment and maintaining the desired temperature inside the equipment. Insulating fire bricks are also resistant to thermal shock, meaning they can withstand rapid changes in temperature without cracking or failing. This makes them suitable for applications where the equipment goes through frequent heating and cooling cycles. Furthermore, insulating fire bricks have low thermal conductivity, which means they can effectively limit heat transfer between different areas of the refractory lining. This helps to prevent hot spots and temperature imbalances, ensuring uniform heat distribution throughout the equipment. Overall, insulating fire bricks are a versatile and effective choice for refractory lining applications, providing excellent thermal insulation, resistance to thermal shock, and uniform heat distribution.

- Q: Can insulating fire bricks be used in the construction of hearths?

- Yes, insulating fire bricks can be used in the construction of hearths. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in hearth construction. They help to retain heat and prevent the loss of energy, ensuring efficient and effective heating.

- Q: Are insulating fire bricks eco-friendly?

- Yes, insulating fire bricks can be considered eco-friendly. They are typically made from natural and sustainable materials such as clay and shale, which are readily available and do not deplete natural resources. Additionally, their high insulation properties help reduce energy consumption, making them an environmentally responsible choice.

- Q: Insulation brick should pay attention to external walls?

- Before the tile is adhered, the water spraying device is applied to spray the wet water on the adhered base layer so as not to flow better.

- Q: Can insulating fire bricks be used in the construction of glass melting tanks?

- Indeed, the utilization of insulating fire bricks is possible for the construction of glass melting tanks. These bricks are precisely engineered to endure elevated temperatures and offer exceptional insulation characteristics. Thus, they prove to be perfect for application in glass melting tanks, where intense temperatures are necessary for the glass to melt. The insulation properties of these bricks aid in minimizing heat dissipation and preserving the desired temperature within the tank, thereby enhancing the efficiency and cost-effectiveness of the glass melting procedures. Moreover, the durability and thermal shock resistance of insulating fire bricks make them a dependable option for constructing glass melting tanks.

- Q: Can insulating fire bricks be used in biomass power plants?

- Yes, insulating fire bricks can be used in biomass power plants. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for lining furnaces and boilers in biomass power plants. They help to increase energy efficiency by minimizing heat loss, ensuring optimal combustion, and reducing the overall energy consumption of the plant.

- Q: Which kind of balcony heat preservation material is better?

- New inorganic insulation material, this material thickness is thin, in 2-3 centimeters line, direct smear on the top of the house, without auxiliary materials, the price is higher than rock wool, aluminum silicate cotton.

Send your message to us

Insulating Fire Brick - Mullite Refractory Jm 23

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords