All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

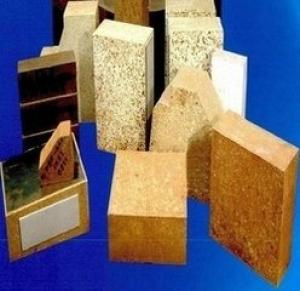

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can refractory bricks be used in the construction of boilers for biomass gasification?

Yes, refractory bricks can be used in the construction of boilers for biomass gasification. Refractory bricks are designed to withstand high temperatures and harsh conditions, making them suitable for use in boilers where biomass is converted into gas. These bricks can help to protect the inner walls of the boiler from the corrosive effects of biomass gasification process, ensuring the longevity and efficiency of the boiler system.

Can refractory bricks be used in gasifiers?

Yes, refractory bricks can be used in gasifiers. Refractory bricks are specifically designed to withstand high temperatures and harsh conditions, making them suitable for use in gasifiers where intense heat and chemical reactions occur. These bricks help to protect the gasifier walls from damage caused by the extreme heat and corrosive environment, ensuring the durability and longevity of the gasifier.

Can refractory bricks be used in environments with high levels of electromagnetic interference?

Refractory bricks can generally be used in environments with high levels of electromagnetic interference, as they are designed to withstand extreme temperatures and provide insulation. However, it is essential to consider the specific characteristics and requirements of the refractory bricks, as well as the level and type of electromagnetic interference present in the environment, to ensure their optimal performance and longevity.

What are the safety precautions to consider when working with refractory bricks?

When working with refractory bricks, there are several safety precautions that should be considered. First and foremost, it is essential to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against potential hazards. Refractory bricks can produce dust and fine particles when handled or cut, which may be harmful if inhaled or come into contact with the skin.

Furthermore, it is important to work in a well-ventilated area to minimize exposure to airborne particles and fumes. Adequate ventilation helps to disperse any harmful substances or gases that may be released during the installation or removal of refractory bricks.

Additionally, refractory bricks can be heavy and difficult to handle, so proper lifting techniques should be employed to prevent strains or injuries. It is crucial to use mechanical aids or seek assistance when necessary to avoid overexertion.

Moreover, refractory bricks are often used in high-temperature applications, so it is crucial to be aware of the risks associated with thermal burns. Workers should be trained on how to handle hot bricks safely and use appropriate tools or equipment to minimize direct contact with them.

Lastly, regular maintenance and inspection of refractory brickwork should be conducted to identify any potential hazards, such as cracks or loose bricks. Prompt repairs or replacements should be carried out to ensure the integrity and safety of the structure.

Are refractory bricks resistant to molten steel?

Yes, refractory bricks are resistant to molten steel.

Wholesale Refractory Bricks from supplier in Egypt

Our team of experts is well-equipped to provide you with the best solutions for your refractory brick needs in Egypt. We understand the unique requirements of various industries, such as steel, cement, glass, and petrochemicals, and can offer tailored products to meet your specific needs.

We have a wide range of refractory bricks, including high alumina bricks, fire clay bricks, silica bricks, magnesia bricks, and insulation bricks. These bricks are sourced from reputable manufacturers and are of the highest quality, ensuring excellent performance and durability.

In addition to supplying refractory bricks, we also offer comprehensive services to our clients in Egypt. Our sales team is dedicated to providing exceptional customer service, assisting you with product selection, and offering competitive pricing. We understand the importance of timely and efficient deliveries, and we work closely with reliable logistics partners to ensure that your orders are delivered on time.

Our team of experts is also available to provide technical support and assistance throughout your project. Whether you need guidance on brick selection, installation techniques, or troubleshooting, our knowledgeable engineers are here to help. We can provide on-site inspections, recommend the most suitable products for your specific application, and offer solutions to any challenges you may encounter.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide all-in-one procurement solutions for refractory bricks in Egypt. This means that we can handle all aspects of your procurement process, from sourcing and supply to logistics and after-sales support. Our strong global network and relationships with leading manufacturers enable us to offer competitive prices without compromising on quality.

With our extensive product range, valuable project experience, and comprehensive services, we are your trusted partner for all your refractory brick needs in Egypt. Contact us today to discuss your requirements and discover how we can support your projects.

We have a wide range of refractory bricks, including high alumina bricks, fire clay bricks, silica bricks, magnesia bricks, and insulation bricks. These bricks are sourced from reputable manufacturers and are of the highest quality, ensuring excellent performance and durability.

In addition to supplying refractory bricks, we also offer comprehensive services to our clients in Egypt. Our sales team is dedicated to providing exceptional customer service, assisting you with product selection, and offering competitive pricing. We understand the importance of timely and efficient deliveries, and we work closely with reliable logistics partners to ensure that your orders are delivered on time.

Our team of experts is also available to provide technical support and assistance throughout your project. Whether you need guidance on brick selection, installation techniques, or troubleshooting, our knowledgeable engineers are here to help. We can provide on-site inspections, recommend the most suitable products for your specific application, and offer solutions to any challenges you may encounter.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide all-in-one procurement solutions for refractory bricks in Egypt. This means that we can handle all aspects of your procurement process, from sourcing and supply to logistics and after-sales support. Our strong global network and relationships with leading manufacturers enable us to offer competitive prices without compromising on quality.

With our extensive product range, valuable project experience, and comprehensive services, we are your trusted partner for all your refractory brick needs in Egypt. Contact us today to discuss your requirements and discover how we can support your projects.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Dominica

- Refractory Bricks in Mauritania

- Raw Materials For Refractory in India

- Refractory Bricks in Turkmenistan

- Refractory Bricks in Gabon

- Raw Materials For Refractory in Djibouti

- Monolithic Refractories in Benin

- Refractory Bricks in Kenya

- Refractory Bricks in Argentina