All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What role does tension control play in coil winding for the construction of oil and gas infrastructure?

Tension control plays a crucial role in coil winding for the construction of oil and gas infrastructure. It ensures that the wire or cable being wound onto the coil is applied with the right amount of tension. This is important because improper tension can lead to various issues such as wire breakage, coil deformation, or uneven winding. By maintaining proper tension control, coil winding processes can achieve consistent and high-quality coils, ensuring reliable performance and durability of the oil and gas infrastructure.

How are steel coils used in the automotive aftermarket for repair and replacement parts?

Steel coils are used in the automotive aftermarket for repair and replacement parts as they serve as the primary raw material for manufacturing various components such as springs, suspension systems, and body panels. These coils are formed and shaped into specific parts to ensure proper fit and functionality in vehicles. Additionally, steel coils provide the required strength and durability to withstand the demanding conditions of the automotive industry, making them an essential resource for producing high-quality aftermarket parts.

How are steel coils prepared for the production of electrical panels?

Steel coils are prepared for the production of electrical panels through a series of steps. First, the coils are uncoiled and flattened to remove any curvature. Then, the steel is cut into appropriate sizes and shapes using shearing or slitting machines. The edges are then trimmed and the steel is cleaned to remove any impurities. Finally, the prepared steel is coated with protective layers and formed into the desired shapes, ready to be used in the production of electrical panels.

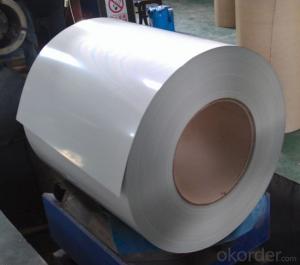

Wholesale Steel Coils from supplier in Egypt

Whether you are in need of hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, or any other type of steel coils, we have a solution for you. Our sales team is dedicated to providing excellent customer service and ensuring that your needs are met.

When you request a quotation from us, we will provide you with competitive prices and detailed specifications for the steel coils you require. Our team of experts is also available to provide technical support and guidance, helping you make informed decisions about the best steel coils for your specific applications.

As a subsidiary of CNBM, we have access to a vast network of suppliers, ensuring a reliable and efficient supply chain. This allows us to offer timely delivery of your steel coils, minimizing any potential delays or disruptions to your projects.

We understand the importance of quality in the steel industry, and we take pride in supplying high-quality steel coils that meet international standards. Our products undergo strict quality control processes to ensure their durability and performance.

In addition to our sales and technical support services, we also offer after-sales service to address any concerns or issues you may have. We strive to build long-term relationships with our customers, providing ongoing support and assistance throughout the duration of your projects.

Choose us as your supplier of steel coils in Egypt, and benefit from our comprehensive services, competitive prices, and expertise in the industry. Contact us today to discuss your requirements and how we can assist you.

When you request a quotation from us, we will provide you with competitive prices and detailed specifications for the steel coils you require. Our team of experts is also available to provide technical support and guidance, helping you make informed decisions about the best steel coils for your specific applications.

As a subsidiary of CNBM, we have access to a vast network of suppliers, ensuring a reliable and efficient supply chain. This allows us to offer timely delivery of your steel coils, minimizing any potential delays or disruptions to your projects.

We understand the importance of quality in the steel industry, and we take pride in supplying high-quality steel coils that meet international standards. Our products undergo strict quality control processes to ensure their durability and performance.

In addition to our sales and technical support services, we also offer after-sales service to address any concerns or issues you may have. We strive to build long-term relationships with our customers, providing ongoing support and assistance throughout the duration of your projects.

Choose us as your supplier of steel coils in Egypt, and benefit from our comprehensive services, competitive prices, and expertise in the industry. Contact us today to discuss your requirements and how we can assist you.