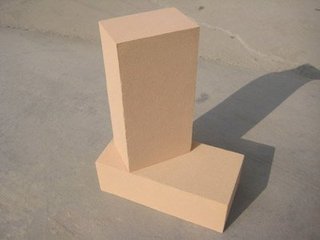

High Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 brick insulation material

Thermal insulation brick is a kind of polymer material synthesis of a new type of materials used.

2 insulation brick is introduced

A, fully replace aluminous model board, honeycomb panel, curtain wall, such as common decoration materials, multi-functional integration, a construction can solve the heat preservation decoration two functional requirements, level off is smooth and beautiful adornment sex is strong.

2, high strength, good rigidity, light seismic and wind resistance, creep, superior performance, reduce building load and more economic and durable.

Three fire retardant, heat preservation and heat insulation, sound insulation, heat insulation, anti-cracking waterproof, according to 65% of building energy efficiency requirements for construction design.

Four Jin Anhua, easy installation and finishing products, process, shorten the construction period and quality easy to control.

Five, don't use aluminum, steel, keel support, set in the installation, reduce the gap between the insulation board and wall body.Increased security system.

Six, no radiation, green environmental protection, can be widely used in all kinds of public buildings and home interior decoration.

Seven, installed with cement, save a lot of material, manpower and time.Reduce the air pollution caused by production cement burning, accord with the requirement of green low carbon environmental protection.

Eight, more than 70 carrier lifetime, more than 20 years of decoration life for a long time, to adapt to a variety of areas such as zha climate and complex environment.With the quality of class international aluminous model board, aluminum veneer and steel hanging stone, compared to reduce bearing 30% to 90%

Nine, double efficacy, shorten time limit, the comprehensive cost declined from 30% to 70%.

- Q: Can insulating fire bricks be used in the construction of glass fusing kilns?

- Indeed, glass fusing kilns can utilize insulating fire bricks. These bricks are specifically crafted to endure extreme temperatures and deliver exceptional insulation, rendering them fitting for kiln application. They aid in retaining heat and guaranteeing uniform distribution within the kiln, a critical component of the glass fusing procedure. Moreover, insulating fire bricks possess the advantages of being lightweight and long-lasting, making them an ideal choice for kiln construction. They effectively minimize heat loss, enhance energy efficiency, and uphold a steady temperature inside the kiln, all of which are pivotal factors for achieving successful glass fusing.

- Q: How to reinforce a porous brick foundation?

- Enlarged section method: it is used for the relatively shallow foundation with independent depth, strip foundation, raft foundation, box foundation and pile foundation applicabilityPoor.

- Q: Can insulating fire bricks be used in high-temperature insulation for cryogenic applications?

- No, insulating fire bricks are not suitable for high-temperature insulation in cryogenic applications.

- Q: Are insulating fire bricks suitable for insulation in boilers for steam generation?

- Insulating fire bricks are a suitable choice for insulation in steam generation boilers. Specifically designed to possess exceptional thermal insulation properties, these bricks are perfect for high-temperature applications like boilers. With their low thermal conductivity, they effectively minimize heat transfer and prevent heat loss. This insulation capability aids in maintaining optimal temperatures within the boiler, thereby enhancing energy efficiency and reducing fuel consumption. Moreover, these bricks can withstand thermal shock, making them highly resistant to the extreme temperature fluctuations encountered during steam generation. Overall, incorporating insulating fire bricks into steam generation boilers can significantly improve the system's thermal efficiency and performance.

- Q: Are insulating fire bricks fire-rated?

- Indeed, insulating fire bricks possess fire-rating. They are purposefully crafted to endure elevated temperatures and furnish superior thermal insulation in diverse applications. Fashioned from a distinct ceramic material with minimal thermal conductivity, these bricks possess the capability to retain heat and impede its transmission to the surroundings. Such attribute endows them with remarkable fire resistance, thereby safeguarding the structures they are employed in. Commonly employed within furnaces, kilns, fireplaces, and other environments characterized by high temperatures, insulating fire bricks play a pivotal role in ensuring fire protection.

- Q: Are insulating fire bricks resistant to spalling?

- Yes, insulating fire bricks are resistant to spalling. Insulating fire bricks are specifically designed to withstand high temperatures and thermal shock, making them highly resistant to spalling. Spalling refers to the cracking and breaking of bricks due to exposure to extreme heat. Insulating fire bricks are made from high-quality refractory materials that have a low thermal conductivity, which helps to reduce the transfer of heat and minimize the risk of spalling. Additionally, insulating fire bricks have a high melting point, which makes them ideal for applications that involve high temperatures. Therefore, insulating fire bricks are commonly used in furnaces, kilns, and other high-temperature environments where spalling is a concern.

- Q: How do insulating fire bricks affect the overall weight capacity of a structure?

- Insulating fire bricks can have a significant impact on the overall weight capacity of a structure. These bricks are specifically designed to have low density and high thermal insulation properties, which means they are lightweight compared to traditional dense firebricks. By using insulating fire bricks, the overall weight of the structure is reduced, allowing for more weight to be allocated to other components or materials. This is particularly beneficial in situations where weight restrictions are a concern, such as in aerospace, automotive, or marine applications. Moreover, the lightweight nature of insulating fire bricks reduces the overall load on the foundation and supporting structures. This can help prevent structural damage and increase the safety and longevity of the entire structure. However, it is important to note that while insulating fire bricks are lighter, they may have slightly lower compressive strength compared to dense firebricks. Therefore, it is crucial to carefully consider the specific requirements of the structure and ensure that the chosen insulating fire bricks can withstand the anticipated load and stresses. In summary, insulating fire bricks positively affect the overall weight capacity of a structure by reducing its overall weight and decreasing the load on supporting structures. However, it is essential to consider the specific application and choose the appropriate insulating fire bricks to ensure structural integrity and safety.

- Q: Do insulating fire bricks have good mechanical strength?

- Compared to regular fire bricks, insulating fire bricks typically possess moderate mechanical strength. Although their primary function is to offer exceptional thermal insulation, they can still endure a certain degree of mechanical strain. Nevertheless, it is crucial to acknowledge that their mechanical strength might not be as robust as other fire brick variants explicitly engineered to withstand heavier loads and abrasion. Consequently, if the objective is to attain both high insulation and superior mechanical strength, contemplating the utilization of a blend of insulating fire bricks and regular fire bricks could be necessary.

- Q: Are insulating fire bricks suitable for insulation in gas turbines?

- Insulating fire bricks are not typically suitable for insulation in gas turbines. While they are excellent for high-temperature insulation applications, such as in furnaces and kilns, gas turbines operate at even higher temperatures and require specialized insulation materials. Gas turbines typically utilize thermal barrier coatings, ceramic fiber blankets, or other advanced insulation materials that can withstand the extreme heat and pressure conditions within the turbine. These materials are specifically engineered to provide excellent thermal insulation while also offering other properties such as erosion resistance, low thermal conductivity, and high mechanical strength. Therefore, while insulating fire bricks have their merits in certain applications, they are not the ideal choice for insulation in gas turbines.

- Q: Can insulating fire bricks be used in the construction of hot blast stoves?

- Yes, insulating fire bricks can be used in the construction of hot blast stoves. Insulating fire bricks are designed to have low thermal conductivity, making them effective at reducing heat loss. Hot blast stoves require high temperatures to be maintained for efficient operation, and insulating fire bricks can help in achieving this by minimizing heat transfer to the outer surface of the stove. These bricks also have good insulation properties, which help to conserve energy and improve the overall efficiency of the stove. Additionally, insulating fire bricks are resistant to thermal shock, which is important in hot blast stove applications where frequent temperature fluctuations occur.

Send your message to us

High Quality Insulating Fire Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords