Low Weight,Insulating Refractory Products Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

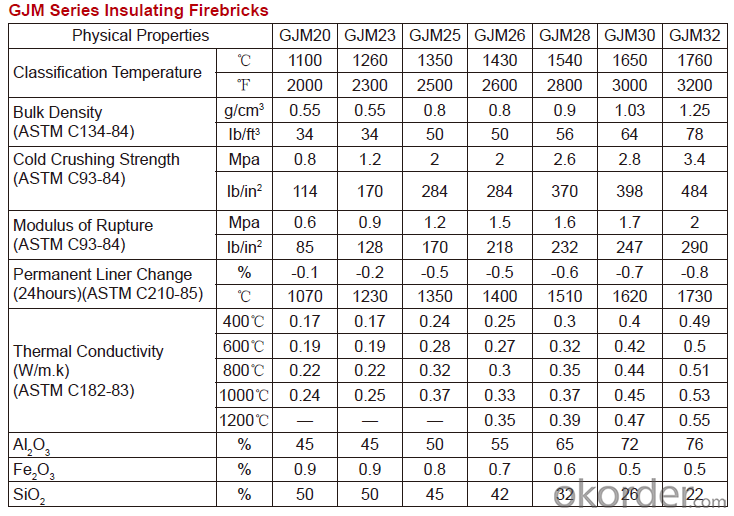

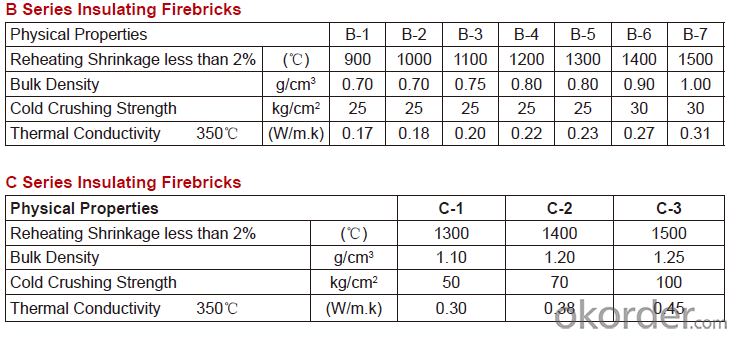

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Insulating fire bricks are not suitable for use in coke ovens. Coke ovens require bricks that can withstand extremely high temperatures and harsh chemical environments. Insulating fire bricks are designed to provide thermal insulation and are not able to withstand the heat and chemical exposure that occurs in coke ovens. Therefore, it is crucial to use refractory bricks specifically designed for coke ovens, which have high resistance to temperature, chemical attacks, and thermal shock. These refractory bricks are typically made from materials such as silica, alumina, and carbon, which can withstand the harsh conditions inside the coke ovens.

- Q: Are insulating fire bricks resistant to carbon dioxide?

- Insulating fire bricks, also known as refractory bricks, are engineered for withstanding high temperatures and displaying resistance to various chemicals and gases. Nonetheless, the level of resistance to carbon dioxide may differ based on the particular type and composition of the insulating fire brick. Carbon dioxide (CO2) is an inert gas usually found in the atmosphere and released when carbon-based fuels are burned. Typically, insulating fire bricks exhibit high resistance to carbon dioxide due to their elevated melting point and the presence of refractory materials like alumina and silica. Nevertheless, extended exposure to high concentrations of carbon dioxide, especially at increased temperatures, may lead to chemical reactions in some insulating fire bricks, resulting in degradation or diminished performance. Therefore, it is crucial to consider the specific application and environment in which the insulating fire bricks will be utilized. If the insulating fire bricks are part of a furnace or kiln that generates substantial amounts of carbon dioxide, it is advisable to select bricks explicitly designed for such conditions. These bricks might possess additional protective coatings or enhanced chemical resistance to ensure their durability and performance. To summarize, although insulating fire bricks generally possess good resistance to carbon dioxide, it is imperative to consider the specific type of brick and the conditions in which it will be employed to guarantee optimal performance and durability.

- Q: Can insulating fire bricks be used in the construction of smelting ovens?

- Indeed, the utilization of insulating fire bricks in the construction of smelting ovens is indeed possible. These fire bricks are specifically engineered to possess a low thermal conductivity, enabling them to effectively retain heat. This particular characteristic renders them particularly well-suited for applications requiring the consistent maintenance of high temperatures, such as smelting ovens. Smelting ovens serve the purpose of melting and refining various metals and minerals. These procedures entail the utilization of exceedingly high temperatures, making it crucial to minimize heat dissipation in order to ensure efficient and effective smelting. By providing exceptional insulation and reducing heat dissipation, insulating fire bricks can contribute to the achievement of this objective. Insulating fire bricks are manufactured using lightweight materials, including ceramic fibers or expanded clay, which are renowned for their superior insulating properties. These fire bricks are capable of withstanding temperatures of up to 3000°F (1650°C), rendering them suitable for the intense heat generated within smelting ovens. Moreover, insulating fire bricks demonstrate resistance against thermal shock, enabling them to endure rapid temperature fluctuations without suffering from cracks or breakages. This quality is of utmost importance in smelting processes, which frequently involve cycles of heating and cooling. Furthermore, insulating fire bricks are highly malleable and can be easily cut or shaped to accommodate specific dimensions or designs. This inherent flexibility renders them highly adaptable for the construction of smelting ovens of varying shapes and sizes. To summarize, the implementation of insulating fire bricks in the construction of smelting ovens is an exceptional choice due to their low thermal conductivity, high resistance to extreme temperatures, ability to withstand thermal shock, and ease of customization. These fire bricks effectively maintain high temperatures, minimize heat dissipation, and ensure the efficiency of smelting processes.

- Q: Are insulating fire bricks suitable for insulation in heat treatment furnaces?

- Yes, insulating fire bricks are suitable for insulation in heat treatment furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them ideal for use in heat treatment furnaces where maintaining consistent and controlled temperatures is crucial. These bricks help minimize heat loss, increase energy efficiency, and ensure uniform heating throughout the furnace, resulting in improved performance and cost savings.

- Q: Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. Insulating fire bricks are known for their excellent thermal insulation properties and can be used to effectively reduce heat transfer in various applications such as kilns, furnaces, and fireplaces. However, in some cases, additional insulation may be required to achieve optimal thermal efficiency. Combining insulating fire bricks with other insulation materials can further enhance the overall insulation performance. For example, ceramic fiber blankets or boards can be used alongside insulating fire bricks to provide additional insulation and to fill any gaps or joints between the bricks. This combination can help minimize heat loss and improve energy efficiency. Furthermore, using multiple insulation materials can also provide other benefits such as increased fire resistance, improved sound insulation, and enhanced structural integrity. By utilizing different insulation materials in combination, it is possible to create a more effective insulation system that meets specific requirements for different applications. It is important to consider the compatibility and compatibility of the different insulation materials when combining them. Each material may have different thermal properties, density, and installation requirements, so it is crucial to follow the manufacturer's recommendations and guidelines for proper installation. In summary, insulating fire bricks can be used in combination with other insulation materials to enhance thermal insulation and improve overall performance in various applications. However, it is essential to ensure compatibility and follow proper installation guidelines for optimal results.

- Q: Can insulating fire bricks be used in the construction of combustion flues?

- Yes, insulating fire bricks can be used in the construction of combustion flues. Insulating fire bricks are designed to withstand high temperatures and are often used to line combustion chambers and flues to provide insulation and prevent heat loss. They have excellent thermal properties, making them suitable for this purpose.

- Q: Can insulating fire bricks be used in space heating applications?

- Indeed, insulating fire bricks can be utilized in space heating scenarios. These bricks possess a design that ensures low thermal conductivity, enabling them to effectively retain and distribute heat within a space heating setup. Crafted from lightweight refractory materials with outstanding insulation properties, these bricks possess the ability to encapsulate heat and prevent its dissipation into the surroundings. Consequently, they prove to be an ideal choice for space heating applications that prioritize energy efficiency. Moreover, insulating fire bricks exhibit a remarkable resilience to high temperatures and thermal shock, rendering them suitable for employment in heating systems that operate at elevated temperatures. All in all, insulating fire bricks emerge as a dependable and efficient alternative for space heating applications.

- Q: Are insulating fire bricks resistant to electrical conductivity?

- Insulating fire bricks exhibit resistance to electrical conductivity. Their composition comprises materials with low electrical conductivity, like ceramic fibers or insulating refractory materials. The primary objective of these fire bricks is to offer thermal insulation, rendering them suitable for situations that demand the containment of high temperatures. Due to their minimal electrical conductivity, insulating fire bricks serve as linings in electrical furnaces, kilns, and other high-temperature apparatuses that necessitate electrical insulation.

- Q: Clay insulation bricks insulation, brick and ordinary clay brick, fireclay, brick distinction, and its use? Thank you

- The insulation brick integrates the excellent heat preservation effect into the wall while building the wall. Low thermal conductivity, high strength, durable, lightweight, simple construction, easy handling, economy, green environmental protection, sound insulation, fire protection etc..

- Q: Can insulating fire bricks be used in lime plants?

- Indeed, insulating fire bricks have the capability to be utilized in lime plants. These bricks are uniquely crafted to possess a remarkably low thermal conductivity, thus enabling them to effectively impede the transfer of heat. In the context of lime plants, where elevated temperatures are necessary for the calcination process, insulating fire bricks can be employed to line the kilns and other zones exposed to high temperatures. By doing so, these bricks aid in the preservation of heat within the lime kilns, resulting in a reduction of energy loss and an enhancement of overall efficiency. Furthermore, insulating fire bricks possess resistance against chemical attacks and are able to endure the harsh conditions experienced in lime plants, rendering them a suitable and appropriate choice for this particular application.

Send your message to us

Low Weight,Insulating Refractory Products Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords