All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

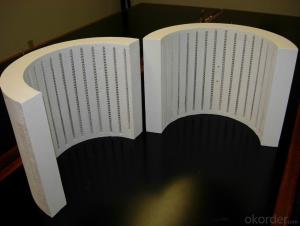

- - Ceramic Fiber Products

- - Refractory Bricks

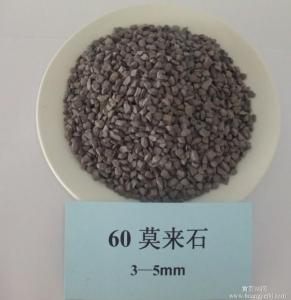

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials resist thermal stress?

Refractory materials resist thermal stress through their ability to withstand high temperatures without undergoing significant deformation or degradation. They possess a combination of high melting points, low thermal expansion coefficients, and excellent thermal conductivity, which allow them to maintain their structural integrity under extreme heat conditions. Additionally, refractory materials often have a high mechanical strength and are chemically stable, further enhancing their ability to resist thermal stress.

How do refractory materials contribute to the reduction of greenhouse gas emissions?

Refractory materials play a crucial role in reducing greenhouse gas emissions by enabling efficient and sustainable industrial processes. These materials possess high heat resistance, allowing them to withstand extreme temperatures in furnaces and kilns used for various manufacturing processes. By maintaining thermal insulation and preventing heat loss, refractory materials improve energy efficiency, thereby reducing the need for excessive fuel consumption and subsequently lowering greenhouse gas emissions. Additionally, their durability and longer lifespan minimize the frequency of material replacements, resulting in reduced resource consumption and environmental impact.

How are refractory cements used in construction?

Refractory cements are used in construction to bond and seal refractory materials, such as bricks, tiles, and castables, in high-temperature applications. These cements have excellent heat resistance and can withstand extreme temperatures, making them ideal for lining furnaces, kilns, and chimneys. They provide thermal insulation, prevent heat loss, and protect the underlying structures from thermal stress and corrosion. Refractory cements are typically mixed with water and applied as a mortar or used as a coating to create a strong and durable bond between refractory materials, ensuring the overall integrity and efficiency of the construction.

Wholesale Refractory Materials from supplier in Brazil

With our strong network of suppliers and strategic partnerships, we are able to offer competitive prices and ensure timely delivery of our products. Our team of experienced professionals is dedicated to providing excellent customer service and technical support, guiding you through every step of the procurement process.

Whether you need refractory bricks, castables, ceramic fibers, or any other refractory material, we have you covered. We source our products from trusted manufacturers worldwide, ensuring that our customers receive high-quality materials that meet their specific needs and requirements.

In addition to our wide product range, we also offer value-added services such as on-site technical consultations, custom product development, and installation support. We understand that each project is unique and may require tailored solutions, and we are committed to delivering the highest level of customer satisfaction.

Furthermore, as a subsidiary of CNBM, we have access to a vast global network of resources and expertise. This allows us to stay up-to-date with the latest industry trends and technologies, ensuring that our customers benefit from the most innovative and efficient solutions.

In summary, when you choose us as your refractory materials supplier in Brazil, you can expect superior quality products, competitive prices, reliable delivery, and exceptional customer service. We are your one-stop solution for all your refractory materials needs, and we look forward to serving you and helping you achieve success in your projects.

Whether you need refractory bricks, castables, ceramic fibers, or any other refractory material, we have you covered. We source our products from trusted manufacturers worldwide, ensuring that our customers receive high-quality materials that meet their specific needs and requirements.

In addition to our wide product range, we also offer value-added services such as on-site technical consultations, custom product development, and installation support. We understand that each project is unique and may require tailored solutions, and we are committed to delivering the highest level of customer satisfaction.

Furthermore, as a subsidiary of CNBM, we have access to a vast global network of resources and expertise. This allows us to stay up-to-date with the latest industry trends and technologies, ensuring that our customers benefit from the most innovative and efficient solutions.

In summary, when you choose us as your refractory materials supplier in Brazil, you can expect superior quality products, competitive prices, reliable delivery, and exceptional customer service. We are your one-stop solution for all your refractory materials needs, and we look forward to serving you and helping you achieve success in your projects.

Hot Search

- Monolithic Refractories in Bangladesh

- Ceramic Fiber Products in Guyana

- Refractory Bricks in Niger

- Raw Materials For Refractory in Malaysia

- Raw Materials For Refractory in Kuwait

- Raw Materials For Refractory in Cambodia

- Raw Materials For Refractory in Gabon

- Monolithic Refractories in Kenya

- Refractory Bricks in Angola

- Raw Materials For Refractory in Indonesia