All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

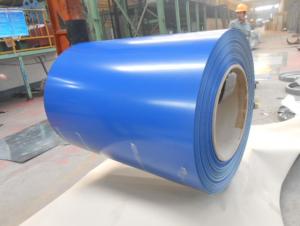

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can stainless steel coils be used in dairy transportation applications?

Yes, stainless steel coils can be used in dairy transportation applications. Stainless steel is a popular choice in industries like dairy due to its resistance to corrosion, easy cleaning, and durability. It ensures the safe and hygienic transportation of dairy products, maintaining their quality and preventing contamination.

How is stainless steel coil inspected upon delivery?

Stainless steel coils are inspected upon delivery through a thorough quality control process. This includes visual examination for any damages, such as scratches or dents, as well as checking the dimensions and weight to ensure they meet the specified requirements. Additionally, the coils are often subjected to various tests, such as chemical composition analysis, mechanical property testing, and surface finish assessment, to ensure the material meets the desired standards and specifications.

What is the cost of stainless steel coil?

The cost of stainless steel coil can vary depending on factors such as the grade of stainless steel, the thickness of the coil, the quantity being purchased, and the current market conditions. It is best to consult with suppliers or manufacturers for accurate pricing information.

What are the different types of surface coatings for stainless steel coils?

There are various types of surface coatings available for stainless steel coils, including but not limited to:

1. Polished finish: Provides a smooth and shiny surface, enhancing the aesthetic appeal of the stainless steel.

2. Brushed finish: Creates a textured, brushed appearance, often used for decorative purposes.

3. Satin finish: Offers a smooth and slightly shiny surface, balancing aesthetics and practicality.

4. Matte finish: Provides a non-reflective surface, ideal for reducing glare and fingerprints.

5. Powder coating: A durable and protective coating applied as a dry powder, providing resistance to corrosion, UV rays, and chemicals.

6. PVD coating: A physical vapor deposition process that creates a thin, decorative, and durable coating in various colors.

7. Galvanized coating: A zinc-based coating that provides excellent corrosion resistance for stainless steel in harsh environments.

8. Epoxy coating: Offers a protective layer that resists abrasion, chemicals, and UV rays, making it suitable for outdoor applications.

9. Cerakote coating: A ceramic-based coating that enhances corrosion resistance and provides a range of colors and finishes.

10. Anodized coating: An electrochemical process that forms a protective oxide layer on the surface, enhancing corrosion resistance and providing various colors.

Wholesale Stainless Steel Coil from supplier in Brazil

With our expertise in supplying Stainless Steel Coils, we cater specifically to customers in Brazil. Our main objective is to provide exceptional sales, quotations, and technical support services for a wide range of Stainless Steel Coil products in this region. Being a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to offer comprehensive procurement services for Stainless Steel Coils in Brazil. Our extensive product range and years of experience in the Brazilian market position us as a valuable partner for your projects.