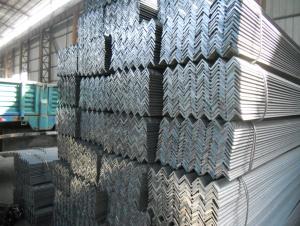

Steel Angle Bar-GB Standard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request.

2. Length: 6m, 9m, 12m.

3. Sizes:

| Size(mm) | Mass(Kg/m) | Size(mm) | Mass(Kg/m) |

| 120*120*10 | 18.055 | 150*150*10 | 22.765 |

| 125*125*8 | 15.504 | 150*150*12 | 27.13 |

| 125*125*10 | 19.133 | | |

Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C.

Material details:

Alloy No | Grade | Element (%) | | ||||

C | Mn | S | P | Si | | ||

| | |||||||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | | ||||

Thickness (mm) | | ||||||

≤16 | >16--40 | >40--60 | >60--100 | | |||

≥ | | ||||||

|

|

|

|

|

| | |

Q235 | B | 235 | 225 | 215 | 205 | | |

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | | |||

Thickness (mm) | | ||||||

| ≤16 | >16--40 | >40--60 | >60--100 | | ||

≥ | | ||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used for support columns?

- Indeed, support columns can utilize steel angles. In construction, steel angles are widely employed as structural elements, serving to offer support and stability for diverse building components. Their robustness, longevity, and load-bearing capacity make them particularly fitting for use as support columns. By virtue of their ability to be tailored and manufactured to meet specific structural needs, steel angles prove to be an excellent option for sustaining heavy loads or providing vertical support in different building applications. Furthermore, steel angles offer flexibility in terms of size, shape, and connection alternatives, enabling tailored column designs that effectively distribute loads and guarantee structural soundness. In summary, steel angles are a dependable and extensively utilized choice for support columns in various construction undertakings.

- Q: How do steel angles compare to aluminum angles in terms of strength and durability?

- Steel angles are generally stronger and more durable than aluminum angles. Steel has a higher tensile strength and can withstand greater loads and impacts compared to aluminum. Additionally, steel is more resistant to bending and warping over time, making it a more durable choice for structural applications.

- Q: Do steel angles have a smooth or textured surface?

- Steel angles typically have a textured surface due to the manufacturing process, which involves rolling or bending steel sheets.

- Q: Are steel angles suitable for manufacturing structural beams?

- Yes, steel angles are suitable for manufacturing structural beams. Steel angles are versatile and commonly used in construction for their strength, durability, and ability to support heavy loads. They can be easily welded or bolted together to form beams of various lengths and sizes, making them a popular choice in structural engineering.

- Q: Are steel angles resistant to UV radiation or fading?

- No, steel angles are not resistant to UV radiation or fading.

- Q: What are the design considerations for incorporating steel angles into a structure?

- When incorporating steel angles into a structure, several design considerations need to be taken into account. First and foremost, the load-bearing capacity of the steel angles must be carefully assessed to ensure they can support the intended loads. The dimensions and thickness of the angles should be determined based on the structural requirements and anticipated stress levels. Additionally, the connection details between the steel angles and other structural elements need to be carefully designed to ensure they provide sufficient strength and rigidity. Considerations should include the type of fasteners, welding techniques, and any additional reinforcement required to achieve the desired structural integrity. Furthermore, factors such as corrosion protection, fire resistance, and durability should also be considered during the design process. Appropriate measures should be taken to prevent rust and corrosion on the steel angles, such as applying protective coatings or using stainless steel. Fire-resistant coatings or fireproofing materials may also be necessary, depending on the building's fire safety requirements. Lastly, aesthetics and architectural considerations may come into play when incorporating steel angles into a structure. The design should take into account the desired visual appearance, whether the angles will be exposed or concealed, and how they will integrate with the overall architectural style. In conclusion, the design considerations for incorporating steel angles into a structure involve assessing load-bearing capacity, connection details, corrosion protection, fire resistance, durability, and aesthetic integration.

- Q: Can steel angles be used for support structures in sports facilities?

- Yes, steel angles can be used for support structures in sports facilities. Steel angles provide excellent strength and stability, making them suitable for supporting various components such as beams, trusses, and frames in sports facilities. They can effectively withstand heavy loads, ensuring the safety and durability of the structure. Additionally, steel angles are versatile and can be easily customized to meet specific design requirements, making them a reliable choice for support structures in sports facilities.

- Q: What are the different types of steel angle connections used in seismic design?

- In seismic design, there are several types of steel angle connections commonly used. These connections are specifically designed to withstand the forces and movements experienced during seismic events. Some of the different types of steel angle connections used in seismic design include: 1. Bolted Flange Plate Connection: This type of connection involves bolting a steel plate to the flanges of two angle sections. It provides good resistance against lateral and vertical forces and can accommodate rotational movements. 2. Welded Flange Plate Connection: Similar to the bolted flange plate connection, this connection involves welding a steel plate to the flanges of two angle sections. It offers high strength and stiffness, but it is less ductile compared to the bolted version. 3. Extended Single Plate Connection: This connection is created by extending a single plate beyond the flanges of two angle sections and then welding it to both the flanges. It provides good resistance against lateral and vertical forces and can accommodate some degree of rotation. 4. Double Angle Connection: In this connection, two angle sections are connected together using bolts or welds. It offers high strength and stiffness and can resist lateral and vertical forces effectively. 5. Diagonal Brace Connection: This type of connection involves connecting diagonal braces to the flanges of two angle sections. It provides enhanced resistance against lateral forces and can effectively control building sway during seismic events. 6. Gusset Plate Connection: This connection involves using a gusset plate to connect two or more angle sections together. It provides good strength and stiffness and can resist lateral and vertical forces effectively. Each of these steel angle connections has its own advantages and disadvantages, and the choice of which connection to use depends on factors such as the structural design requirements, loadings, and the level of seismic activity in the region. It is important to carefully consider these factors and consult with structural engineers to ensure the appropriate connection type is used for a seismic design project.

- Q: Can steel angles be used as reinforcements in masonry walls?

- Yes, steel angles can be used as reinforcements in masonry walls. Steel angles are commonly used in construction to provide additional strength and support to various structures, including masonry walls. They can be strategically placed within the wall to help distribute the load and prevent cracking or structural failure. Steel angles are typically made from galvanized or stainless steel, which makes them resistant to corrosion. This makes them a suitable choice for reinforcing masonry walls, as they can withstand the elements and provide long-lasting support. Additionally, steel angles can be easily customized to fit the specific requirements of the wall, allowing for flexibility in design and reinforcement. Overall, steel angles are a reliable and effective option for reinforcing masonry walls.

- Q: Can steel angles be used for structural purposes?

- Yes, steel angles can be used for structural purposes. Steel angles are commonly used in construction and engineering projects to provide structural support and stability. They are often used to reinforce and strengthen various structural components such as beams, columns, frames, and trusses. Steel angles are known for their high strength and durability, making them suitable for withstanding heavy loads and forces. They are versatile and can be easily welded, bolted, or screwed into place, allowing for easy installation and adaptation to different design requirements. Additionally, steel angles are available in various sizes, lengths, and thicknesses, making them suitable for a wide range of structural applications.

Send your message to us

Steel Angle Bar-GB Standard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords