CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

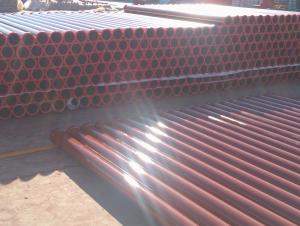

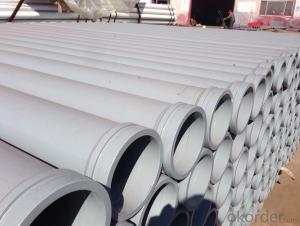

Product Name:CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE

Materials: ST 52

Concrete Pumping Capacity: about 20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available.

Scope of Application of the Equipment

CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete pipe and its major components

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE according to customers request?

A4: Yes, we can produce CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: How often should concrete pump pressure gauges be inspected and replaced?

- Regular inspections of concrete pump pressure gauges are necessary to ensure they are accurate and functioning properly. The frequency of inspections and replacements may vary depending on the specific conditions and usage of the pump. However, it is generally recommended to inspect and replace pressure gauges at least once a year or after every 500 pumping hours, whichever comes first. This regular schedule helps prevent any potential accuracy or functionality issues that could impact the safety and efficiency of the pumping operations. It is also essential to adhere to the manufacturer's recommendations and guidelines for pressure gauge maintenance and replacement to maintain optimal performance and longevity.

- Q: What are the different types of concrete pump hopper agitator blades?

- In the construction industry, there exists a variety of concrete pump hopper agitator blades. These blades have different designs and functions, all aimed at efficiently mixing and agitating the concrete mixture in the hopper. By achieving a consistent and homogeneous mixture, the concrete can be pumped onto the project site effectively. 1. Paddle Blades: The most commonly used agitator blades in concrete pump hoppers are paddle blades. These blades have a flat, paddle-like design that effectively mixes the concrete ingredients. They are typically made of high-quality steel or hardened rubber to ensure durability and optimal performance. 2. Helical Blades: Another type of agitator blade is the helical blade, which has a spiral shape. This design creates a gentle, swirling motion within the hopper, preventing the formation of lumps and ensuring a smooth and well-mixed concrete mixture. 3. Ribbon Blades: Thin and flat, ribbon blades resemble ribbons and are placed vertically in the hopper. They rotate along their axis to thoroughly mix the concrete ingredients. Ribbon blades are known for their ability to prevent clogging and improve the efficiency of concrete pumping. 4. Fan Blades: With a unique fan-shaped design, fan blades create a powerful airflow within the hopper to agitate the concrete mixture. This type of blade is particularly effective in preventing the segregation of concrete ingredients and maintaining a consistent mixture. 5. Tine Blades: Tine blades feature multiple prongs or tines extending from a central hub. They provide a more aggressive agitation action, making them suitable for mixing heavier concrete mixes or those containing large aggregates. The selection of agitator blades depends on various factors, such as the type of concrete, desired consistency, and specific project requirements. It is crucial to choose the appropriate blade type and perform regular maintenance to optimize the performance and lifespan of the concrete pump hopper agitator.

- Q: What is the role of a concrete pump spectacle plate?

- The main purpose of a concrete pump spectacle plate is to provide a stable and secure platform for the concrete pump to rest on while it is in operation. It serves as a support base for the pump, ensuring that it remains steady and balanced while it pumps concrete. The spectacle plate is typically constructed using durable materials like steel or alloy, which can withstand the weight and pressure exerted by the pump. Its design incorporates various features, such as slots or holes, which allow for the attachment of accessories like clamps or pipes. This facilitates a smooth and efficient transfer of concrete from the pump to the desired location. Additionally, the spectacle plate may also have adjustable elements that enable positioning and alignment adjustments, ensuring precise placement of the concrete. In summary, the spectacle plate is essential for maintaining the stability and functionality of the concrete pump, thereby contributing to the successful completion of construction projects.

- Q: How often should hopper agitator shafts be inspected or replaced in a concrete pump?

- To ensure optimal performance and prevent potential breakdowns, it is important to regularly inspect and maintain the hopper agitator shafts in a concrete pump. The frequency of inspection or replacement depends on factors such as pump usage and operating conditions. As a general rule, it is recommended to inspect the hopper agitator shafts every three to six months. During the inspection, check for signs of wear, damage, or misalignment. If any issues are found, take appropriate measures such as lubricating, realigning, or replacing damaged parts. However, it is crucial to consider the intensity of use, the materials being pumped, and the overall condition of the pump when determining the inspection frequency. For example, if the pump is used heavily or operates continuously, it may be necessary to inspect the agitator shafts on a monthly basis. Regular maintenance and inspection of hopper agitator shafts not only ensure smooth operation but also extend the equipment's lifespan. Detecting and resolving issues in a timely manner can prevent costly repairs or downtime in the future. Additionally, following the manufacturer's maintenance recommendations and guidelines can optimize performance and reliability.

- Q: How can a malfunctioning control box affect the pump's operation?

- The operation of a pump can be negatively affected by a control box that malfunctions. Initially, it can lead to an imprecise or inconsistent control of the pump's functions. This implies that the pump may not initiate or halt at the desired moments or operate at the correct velocity, resulting in ineffective or insufficient pumping. Furthermore, a control box that malfunctions can cause electrical problems, resulting in power fluctuations or even power surges. These electrical complications can harm the pump's motor or other components, leading to premature deterioration or complete malfunction. Moreover, a malfunctioning control box can also disrupt the communication between the pump and other systems. This can impact the pump's capacity to receive or transmit signals, resulting in a lack of synchronization with other equipment or systems that depend on the pump's operation. This lack of synchronization can result in system failures or interruptions in the overall process or operation that the pump supports. In conclusion, a malfunctioning control box can have adverse effects on the operation of a pump including imprecise control, electrical problems, and disruption of communication with other systems. It is essential to regularly inspect and maintain control boxes to prevent these malfunctions and ensure the reliable and efficient operation of pumps.

- Q: Can concrete pump spare parts be inspected for dimensional accuracy before installation?

- Yes, concrete pump spare parts can be inspected for dimensional accuracy before installation. By conducting a thorough inspection, one can ensure that the spare parts meet the required specifications and will fit properly into the pump system. This pre-installation inspection helps prevent any potential issues or damage during operation, ensuring the efficient and reliable functioning of the concrete pump.

- Q: How can one identify the need for replacement of concrete pump spare parts?

- The need for replacement of concrete pump spare parts can be determined by observing specific signs and conducting regular maintenance checks. To begin with, it is crucial to keep track of the concrete pump's performance. If there is a decrease in efficiency or a noticeable reduction in output, it could indicate the requirement for replacement parts. This could be a result of worn-out components that are impacting the pump's ability to deliver concrete effectively. Another indication to be mindful of is any unusual noise emanating from the pump. Excessive or abnormal noise can be a sign of problems with the moving parts, such as bearings or seals, which may need to be substituted. It is also essential to inspect the wear and tear of the spare parts. Components like hoses, pipes, and seals can deteriorate over time due to the abrasive nature of concrete. If there are observable signs of wear, such as cracks, leaks, or bulges, it is likely that these parts need to be replaced. Conducting regular maintenance checks is critical in identifying the need for replacement parts. This involves examining the condition of key components, such as the piston, cylinder, and valves, and ensuring that they are clean, properly lubricated, and functioning correctly. Any signs of damage, corrosion, or excessive wear should be promptly addressed to prevent further harm to the pump and the need for more extensive repairs. In conclusion, by closely monitoring the concrete pump's performance, listening for abnormal noise, inspecting for wear and tear, and regularly conducting maintenance checks, one can effectively determine the need for replacement of concrete pump spare parts. Timely replacement of these parts can contribute to maintaining the pump's efficiency and prolonging its lifespan.

- Q: How to judge the concrete pipeline blockage?

- Listen to the ear, there is rustling sound as normal, there is a piercing sound for the blockage

- Q: Can concrete pump spare parts be customized with branding or logos?

- Yes, concrete pump spare parts can be customized with branding or logos. Many manufacturers and suppliers offer the option to customize spare parts with branding or logos according to the specific requirements of the customer. This customization can include adding logos, names, or specific branding elements onto the spare parts. It not only enhances the aesthetic appeal of the spare parts but also helps in promoting the brand or company. Customized branding or logos on concrete pump spare parts can also serve as a form of identification and help in distinguishing the parts from others in case of repair or replacement needs.

- Q: Can concrete pump spare parts be coated with corrosion inhibitors for long-term storage?

- Concrete pump spare parts have the capability to be coated with corrosion inhibitors in order to ensure long-term storage. Corrosion inhibitors, which are chemicals, can be applied onto metal surfaces to either prevent or minimize the corrosion process. By administering a coating of corrosion inhibitor onto concrete pump spare parts, a protective layer can be formed, preventing any contact between moisture, oxygen, and the metal. Consequently, the chances of corrosion are significantly reduced. This becomes particularly crucial when considering long-term storage, as the spare parts might encounter harsh environmental conditions or be stored in damp areas. Ultimately, the corrosion inhibitor coating serves to extend the lifespan of the spare parts and guarantee their preservation until they are required for use.

Send your message to us

CONCRETE PUMP DELIVERY PIPE WITH SCHWING FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords