PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

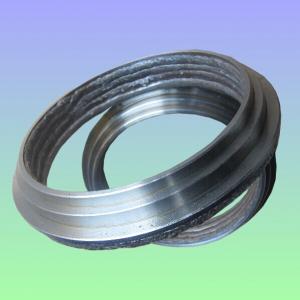

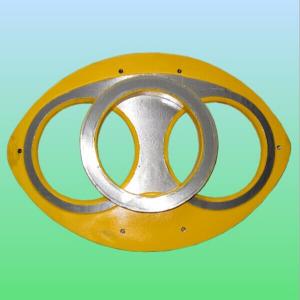

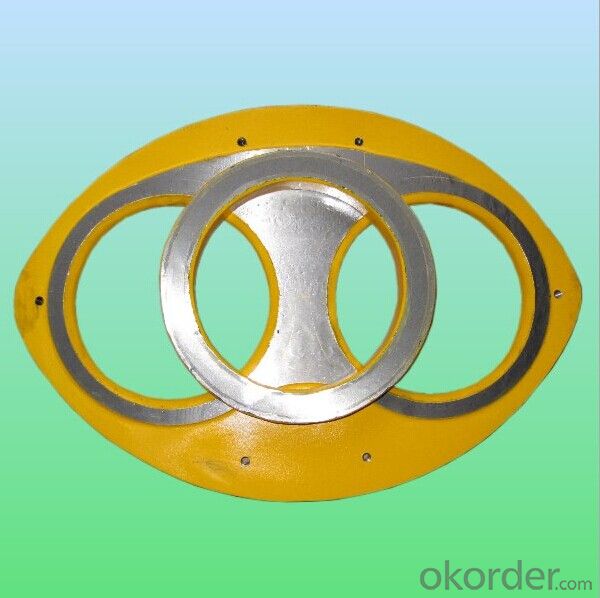

Product Name: PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Putzmeister concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide according to customers request?

A4: Yes, we can produce PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: How can one ensure compatibility between concrete pump spare parts and the pump?

- Ensuring compatibility between concrete pump spare parts and the pump is crucial to maintain the efficiency and performance of the equipment. Here are a few steps to ensure compatibility: 1. Identify the correct model and manufacturer: Gather all the necessary information about the concrete pump, including the model number and manufacturer. This information will help you find the right spare parts that are specifically designed for that particular pump model. 2. Use genuine spare parts: It is always recommended to use genuine spare parts provided by the pump manufacturer or authorized distributors. Genuine parts are specifically designed and tested to meet the pump's specifications, ensuring a perfect fit and compatibility. 3. Check part numbers and specifications: Before purchasing any spare parts, carefully cross-check the part numbers and specifications with the original parts. This will help ensure that the new parts are compatible with the pump. 4. Consult with experts: If you are unsure about the compatibility of certain spare parts, consult with experts or the manufacturer's technical support team. They can provide guidance and advice based on their expertise and experience. 5. Conduct regular maintenance and inspections: Regularly inspect and maintain the concrete pump to identify any wear or damage to the parts. This will help you identify the specific spare parts that need replacement and ensure compatibility with the pump. 6. Prioritize quality and reliability: While cost may be a factor, it is important to prioritize quality and reliability when choosing spare parts. Investing in high-quality parts will ensure better performance, durability, and compatibility with the pump. By following these steps, you can ensure compatibility between concrete pump spare parts and the pump, thereby maximizing its lifespan, performance, and overall efficiency.

- Q: Can I get spare parts for both concrete pumps with and without emergency stop systems?

- Yes, spare parts are available for both concrete pumps with and without emergency stop systems. These spare parts can be sourced from authorized dealers or manufacturers, ensuring the proper functioning and maintenance of both types of concrete pumps.

- Q: How often should hopper screens be cleaned or replaced?

- Hopper screens should be cleaned or replaced regularly, ideally on a quarterly basis, to ensure proper functioning and prevent clogging or damage to the equipment.

- Q: How often should I replace concrete pump spare parts?

- The frequency of replacing concrete pump spare parts depends on several factors such as the quality of the parts, the intensity of usage, and the maintenance practices. However, as a general guideline, it is recommended to inspect and replace worn or damaged concrete pump spare parts on a regular basis, typically every 6 to 12 months, to ensure optimal performance and avoid potential breakdowns or safety hazards.

- Q: How do I find the right part number for a specific concrete pump spare part?

- To find the right part number for a specific concrete pump spare part, you can follow these steps: 1. Start by identifying the make and model of your concrete pump. This information is usually found on the pump itself or in the product documentation. 2. Once you have the make and model, visit the manufacturer's website or contact their customer support directly. They will typically have a parts catalog or database where you can search for the specific part you need. 3. Use the provided search tool or browse through the catalog to find the section related to your concrete pump model. Look for the parts that match your description or function. 4. Pay attention to the part numbers listed alongside the descriptions. These numbers are usually unique identifiers for each specific part. Make note of the part number(s) that match the spare part you require. 5. If you are unable to find the required part number on the manufacturer's website or catalog, consider reaching out to authorized dealers or distributors of the concrete pump brand. They may have additional resources or access to parts that are not readily available elsewhere. By following these steps and utilizing the manufacturer's resources, you should be able to find the right part number for your specific concrete pump spare part.

- Q: Can concrete pump spare parts be replaced individually, or should they be replaced as a set?

- Concrete pump spare parts can be replaced individually, as there is no requirement to replace them as a set. This allows for more cost-effective and efficient maintenance, as only the specific part that needs replacement can be addressed.

- Q: What is the role of a concrete pump hopper grate spring?

- The role of a concrete pump hopper grate spring is to provide tension and support to the hopper grate in a concrete pump. The grate spring is typically made of durable and flexible material, such as steel or rubber, and is designed to keep the hopper grate securely in place while allowing it to move and flex as needed during the concrete pumping process. The hopper grate spring helps to prevent the hopper grate from becoming dislodged or damaged by the force and vibrations generated by the concrete pump. It ensures that the grate remains properly aligned and in position, allowing for the smooth and efficient flow of concrete into the pump. Additionally, the grate spring helps to reduce the impact and stress on the hopper grate, extending its lifespan and reducing the need for frequent repairs or replacements. It acts as a buffer, absorbing and distributing the forces exerted on the grate, which can be significant due to the weight and pressure of the concrete being pumped. Overall, the concrete pump hopper grate spring plays a crucial role in maintaining the integrity and functionality of the hopper grate, ensuring the safe and efficient operation of the concrete pump.

- Q: What is the purpose of a concrete pump control panel?

- The purpose of a concrete pump control panel is to provide operators with a centralized interface to control various functions and parameters of the concrete pump. This control panel allows operators to start and stop the pump, control the speed and direction of the pump, and monitor and adjust the flow and pressure of the concrete being pumped. It also provides safety features such as emergency stop buttons and alarms to protect both the operators and the equipment. Additionally, the control panel may include diagnostic features that display real-time data and alerts for maintenance and troubleshooting purposes. Overall, the purpose of a concrete pump control panel is to enhance efficiency, accuracy, and safety in the operation of the concrete pumping process.

- Q: Can I get spare parts for both single-cylinder and multi-cylinder concrete pumps?

- Yes, you can get spare parts for both single-cylinder and multi-cylinder concrete pumps. Many manufacturers and suppliers offer spare parts for different types of concrete pumps, including both single-cylinder and multi-cylinder models. These spare parts can include components such as hydraulic cylinders, pistons, seals, valves, hoses, and other essential parts that may need replacement due to wear and tear or damage. It is essential to reach out to the specific manufacturer or supplier of your concrete pump to inquire about the availability and compatibility of spare parts for your particular model.

- Q: Are there any specific safety precautions for handling concrete pump spare parts?

- Yes, there are specific safety precautions for handling concrete pump spare parts. It is important to wear appropriate personal protective equipment, such as gloves and safety glasses, to prevent injuries. Additionally, one should ensure that the work area is clean and well-organized to avoid accidents. Proper training and knowledge of the equipment and its parts is also crucial to handle them safely. Regular inspections and maintenance of the spare parts should be conducted to identify any potential hazards and prevent accidents.

Send your message to us

PUTZMEISTER Spectacle Wear Plate and Cutting Ring Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords