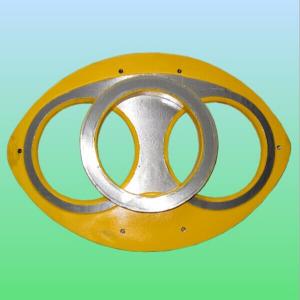

PUTZMEISTER Spectacle Plate Tungsten Carbide DN230

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: Tungsten Carbide Spectacle Plate DN230

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Putzmeister concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

3. Package

Every 60pcs PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 according to customers request?

A4: Yes, we can produce PUTZMEISTER Tungsten Carbide Spectacle Plate DN230 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: What are the signs of wear and tear in concrete pump spare parts?

- Concrete pump spare parts may exhibit signs of wear and tear, which should not be overlooked. Some indicators include: 1. Surface damage: Cracks, dents, or scratches on pipes and hoses can signify wear and tear, particularly if they are extensive or deep. 2. Corrosion: Metal components like couplings or clamps may display signs of corrosion such as rusting or pitting, which can weaken the part and affect its functionality. 3. Leaks: Notable leaks in seals or gaskets can suggest wear and tear. Material degradation or improper installation can cause leaks, impacting the pump's efficiency and performance. 4. Decreased performance: Wear and tear in concrete pump spare parts can result in reduced overall performance. For instance, worn-out wear plates can diminish pumping capacity or increase energy consumption. 5. Heightened noise or vibrations: If noise levels or vibrations intensify while operating the concrete pump, it may indicate wear and tear in the spare parts. Imbalances, misalignments, or loose components can negatively affect the pump's performance and lifespan. 6. Excessive wear on moving parts: Moving parts like pistons or cylinders may exhibit excessive wear and tear, such as scoring or grooving on the surface. This can impede the smooth operation of the pump and potentially cause further damage if left unaddressed. Regular inspection and maintenance of concrete pump spare parts are vital to promptly identify and address any signs of wear and tear. Timely replacement or repair of worn-out components can prevent further damage, ensuring the concrete pump operates efficiently and safely.

- Q: What is the function of a concrete pump outrigger?

- The function of a concrete pump outrigger is to provide stability and support to the concrete pump while it is in operation. The outrigger extends from the sides of the pump and is used to distribute the weight of the pump and concrete being pumped, preventing it from tipping over or causing any instability.

- Q: Are there any maintenance tips to extend the lifespan of concrete pump spare parts?

- Concrete pump spare parts can have their lifespan extended by implementing several maintenance tips. Cleaning the spare parts regularly to remove dirt, debris, and concrete buildup is essential. This can be achieved by using a brush, water, and mild detergent. The cleaning process helps prevent corrosion and ensures smooth operation. Proper lubrication of the moving parts is crucial to reduce friction and wear. It is important to adhere to the manufacturer's recommendations for lubrication intervals and use high-quality lubricants. The lubrication points should be inspected regularly, and any worn-out or damaged lubrication components should be replaced. Regular inspections of all spare parts are necessary to identify any signs of wear, damage, or misalignment. Any issues that are identified should be promptly repaired or replaced. Moreover, following the maintenance schedule provided by the manufacturer is essential to address any potential problems before they escalate. When the spare parts are not in use, they should be stored in a clean and dry environment to prevent rust and corrosion. Protection from extreme temperatures, moisture, and direct sunlight is also important. Additionally, the spare parts should be stored in a way that prevents any damage or deformation. Using the concrete pump in accordance with the manufacturer's guidelines is crucial. Overloading, excessive pressure, or improper operation can lead to premature wear and damage to the spare parts. Proper training should be provided to the operators to ensure they understand the correct usage techniques. Furthermore, regular maintenance of the concrete pump itself is important. This includes cleaning, lubrication, and inspections. By addressing any potential issues, the lifespan of the spare parts can be prolonged. By adhering to these maintenance tips, the need for frequent replacements of concrete pump spare parts can be reduced, resulting in long-term cost savings.

- Q: What are the most commonly replaced spare parts for concrete pumps?

- The most commonly replaced spare parts for concrete pumps are typically wear parts such as concrete delivery pipes, rubber hoses, and wear plates. Other commonly replaced parts include seals, gaskets, pistons, and hydraulic components.

- Q: How to operate the concrete pump?

- All the bolts of the pumping unit shall be fastened, and the pipe joints shall be tightly sealed. The protective devices shall be complete and reliable

- Q: How much is the pump for a month?

- In the mud, the price is about 25 yuan per square, according to my experience, more than 175000 points per month can pump 7000 yuan, totaling $

- Q: How often should hopper grate springs be inspected or replaced in a concrete pump?

- Hopper grate springs in a concrete pump should be inspected regularly to ensure optimal performance and prevent any potential issues. The frequency of inspection or replacement depends on several factors such as the pump's usage, operating conditions, and the manufacturer's recommendations. However, a general guideline is to inspect the hopper grate springs at least once every six months or after every 500 hours of operation, whichever comes first. During the inspection, it is important to thoroughly examine the springs for any signs of wear, damage, or deformation. Look for cracks, excessive rust, or loss of tension in the springs. If any of these issues are detected, immediate replacement is necessary to maintain the proper functioning of the hopper grate system. Regular inspection and timely replacement of hopper grate springs are crucial to prevent clogging or blockage in the hopper, which could lead to pump malfunctions or downtime. It is advisable to consult the concrete pump manufacturer's guidelines or seek assistance from a professional technician to determine the specific inspection and replacement intervals based on the pump's make and model.

- Q: How do I identify the specific spare parts I need for my concrete pump?

- To identify the specific spare parts you need for your concrete pump, you can follow these steps: 1. Consult the user manual: Start by referring to the user manual provided by the manufacturer. It typically contains a detailed parts list along with part numbers and descriptions. The manual may also include diagrams or illustrations to help you identify the required spare parts. 2. Contact the manufacturer: Reach out to the manufacturer of your concrete pump. They will have the most accurate and up-to-date information about the spare parts for your specific model. Provide them with the model number and any other relevant details to ensure accurate identification of the required parts. 3. Engage with authorized dealers or distributors: If the manufacturer is unable to directly provide you with the spare parts, they can often refer you to authorized dealers or distributors. These professionals specialize in concrete pump parts and can help you identify the specific spare parts you need. Share the model number and any other relevant details to assist them in finding the correct parts. 4. Take pictures or measurements: If you are unable to find the required information through the manual, manufacturer, or authorized dealers, you can take pictures or measurements of the damaged or worn-out parts. This will help in visually identifying the parts and providing accurate dimensions, which can be shared with suppliers or experts in the field who may be able to assist you further. 5. Online research: Utilize online resources such as parts catalogs, forums, or websites dedicated to concrete pump spare parts. These platforms often have extensive databases and knowledgeable communities that can help you identify the specific spare parts you need. Search for your concrete pump model and explore the available resources to find the relevant parts. Remember to prioritize quality and authenticity while purchasing spare parts for your concrete pump. It is essential to buy from reputable sources to ensure the durability and longevity of your equipment.

- Q: Are there any specific guidelines for the storage and handling of concrete pump spare parts during transportation?

- Yes, there are specific guidelines for the storage and handling of concrete pump spare parts during transportation. These guidelines are in place to ensure the safe and efficient transportation of the spare parts, as well as to minimize the risk of damage or loss. Firstly, it is important to ensure that the spare parts are properly packaged and protected. This includes using appropriate packaging materials such as cardboard boxes, bubble wrap, or foam padding to prevent any physical damage during transit. The spare parts should be securely packed to prevent any movement or shifting during transportation. Additionally, it is recommended to label the packages clearly with the contents and any specific handling instructions. This will help the transport personnel to handle the spare parts correctly and avoid any mishandling or confusion. Furthermore, it is essential to choose a reliable and experienced transportation service provider who has expertise in handling delicate and sensitive items like concrete pump spare parts. They should have proper equipment, such as pallet jacks or forklifts, to handle and move the spare parts safely. During transportation, it is important to ensure that the spare parts are loaded and secured properly in the transport vehicle. This may involve using straps, ropes, or other securing devices to prevent any movement or shifting of the packages. In terms of temperature control, it is vital to consider the specific requirements of the spare parts. Some parts may be sensitive to extreme temperatures and require special handling or climate-controlled transportation. It is important to consult with the manufacturer or supplier of the spare parts to determine any specific temperature or climate requirements. Overall, following these guidelines will help ensure the safe and secure transportation of concrete pump spare parts, reducing the risk of damage or loss and ensuring their readiness for use when they reach their destination.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Yes, spare parts for concrete pump boom arms and pipes are available. Many manufacturers and suppliers offer a wide range of spare parts specifically designed for concrete pump boom arms and pipes. These spare parts can be easily found and purchased from authorized dealers or online stores. It is important to ensure that you provide accurate specifications and details of your concrete pump model to find the correct spare parts for replacement or repair.

Send your message to us

PUTZMEISTER Spectacle Plate Tungsten Carbide DN230

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords