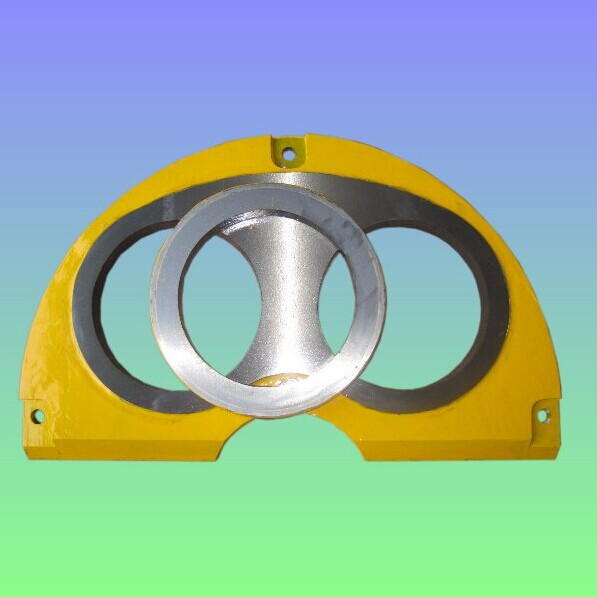

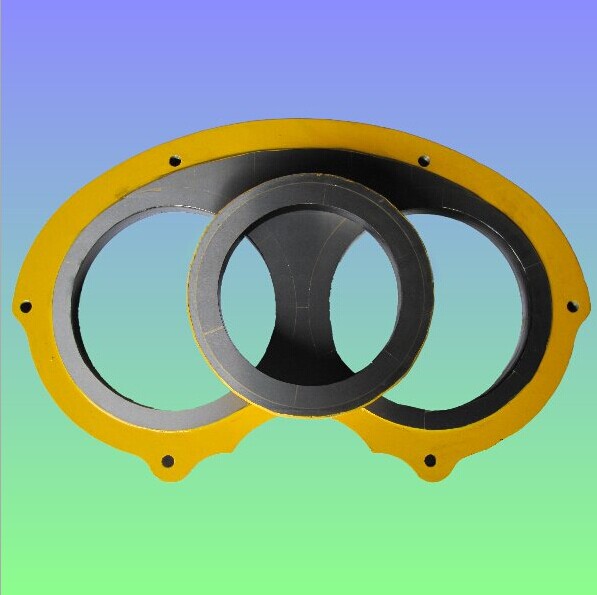

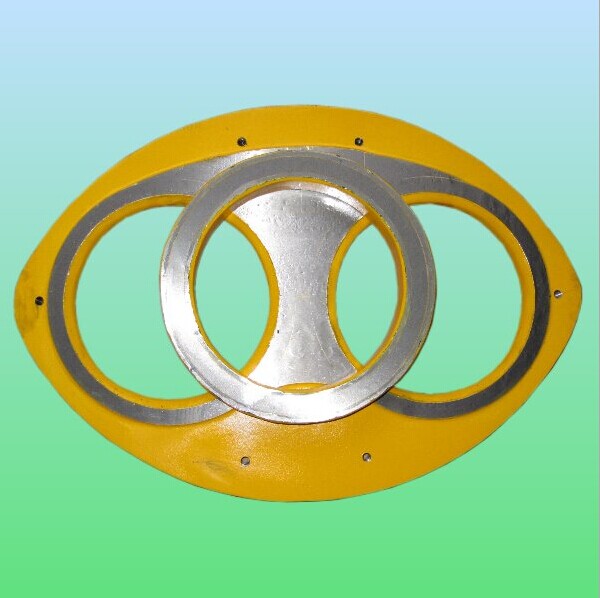

Tungsten Carbide Zoomlion Spectacle Plate DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Tungsten Carbide Zoomlion Spectacle Plate DN230

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade.

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Zoomlion concrete pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our Tungsten Carbide Zoomlion Spectacle Plate DN230 have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs Tungsten Carbide Zoomlion Spectacle Plate DN230 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Tungsten Carbide Zoomlion Spectacle Plate DN230 according to customers request?

A4: Yes, we can produce Tungsten Carbide Zoomlion Spectacle Plate DN230 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

- Q: How often should concrete pump control panels be inspected and replaced?

- Regular inspections should be conducted on concrete pump control panels to ensure proper functioning and detect any potential problems or malfunctions. The frequency of inspections may vary based on factors such as pump type, operating conditions, and manufacturer recommendations. However, a general rule is to thoroughly inspect the panels at least once every six months or after every 500 hours of operation, whichever comes first. Trained professionals should perform these inspections, examining control panel components like buttons, switches, indicators, and wiring for signs of wear or damage. They should also test all functions and safety features to verify the panel's functionality. When it comes to replacement, it is crucial to adhere to the manufacturer's guidelines and recommendations. Typically, control panels have a lifespan of several years, but this can vary depending on factors like panel quality, frequency of use, and maintenance practices. If significant issues or failures are identified during inspections, prompt replacement of the control panel is important to ensure safe and efficient operation of the concrete pump. Ultimately, regular inspections and timely replacement of control panels are vital to minimize the risk of equipment failure, maintain safety on construction sites, and preserve the productivity and longevity of the concrete pump.

- Q: Are there any specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts. Hydraulic fluids contain various chemicals and contaminants that can be harmful to the environment if not disposed of properly. Here are some general guidelines to follow: 1. Check local regulations: Different regions may have specific laws and regulations regarding the disposal of hydraulic fluids. It is important to familiarize yourself with these regulations to ensure compliance. 2. Contain the fluid: Properly contain the hydraulic fluid to prevent leaks or spills during transportation. Use appropriate containers that are designed to handle hazardous materials. 3. Do not mix with other fluids: Do not mix hydraulic fluids with other substances, as this can complicate the disposal process and increase the environmental impact. 4. Find a licensed disposal facility: Locate a licensed facility that handles the disposal of hazardous waste. These facilities have the necessary equipment and expertise to handle hydraulic fluids safely. 5. Follow their instructions: When delivering the hydraulic fluid to the disposal facility, follow their specific instructions for drop-off. They may require certain labeling or documentation to ensure proper handling. 6. Consider recycling options: Depending on the type of hydraulic fluid used, recycling may be an option. Some facilities specialize in recycling hydraulic fluids, which can be a more environmentally friendly solution. 7. Educate your staff: Ensure that all personnel working with hydraulic fluids are aware of the proper disposal procedures and understand the importance of following them. By adhering to these guidelines, you can ensure the safe and responsible disposal of hydraulic fluids used in concrete pump spare parts, minimizing harm to the environment and complying with regulations.

- Q: Can I get spare parts for both concrete pumps with and without agitators?

- Yes, spare parts are available for both concrete pumps with and without agitators.

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Yes, there are specific cleaning and maintenance procedures for concrete pump spare parts. For cleaning, it is important to remove any concrete buildup or residue from the spare parts regularly. This can be done by using a high-pressure water jet or by soaking the parts in a cleaning solution specifically designed for concrete. It is essential to follow the manufacturer's instructions when using cleaning agents to ensure the safety and effectiveness of the cleaning process. In addition to cleaning, regular maintenance is necessary to ensure the longevity and proper functioning of concrete pump spare parts. This includes inspecting the parts for any signs of wear, such as cracks or corrosion, and replacing them if necessary. Lubrication of moving parts, such as bearings or pistons, should also be done as per the manufacturer's recommendations. It is important to note that different concrete pump spare parts may require specific cleaning and maintenance procedures. Therefore, it is advisable to refer to the manufacturer's guidelines or consult with a qualified technician to determine the appropriate cleaning and maintenance procedures for each specific part.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts can vary depending on the specific part in question. However, there are some general signs that can indicate when a concrete pump spare part is experiencing wear and tear. One common sign is visible damage or deterioration on the surface of the part. This can include cracks, chips, or dents on the outer layer of the spare part. These damages can occur due to regular use, exposure to harsh environmental conditions, or accidental impact during operation. Another sign is increased vibration or noise during operation. If a concrete pump spare part is experiencing wear and tear, it may start to produce unusual vibrations or noises that were not present when it was in good condition. This can be an indicator of internal damage or misalignment of the part, which can affect its overall performance and efficiency. Reduced performance or efficiency is also a common sign of wear and tear on concrete pump spare parts. If a part is experiencing wear and tear, it may not function as effectively as before, resulting in decreased pumping capacity, reduced flow rate, or inefficient operation. This can lead to delays in construction projects and increased maintenance costs. Additionally, increased maintenance and repair requirements can indicate wear and tear on concrete pump spare parts. If a part needs to be repaired or replaced more frequently than usual, it could be a sign that it is experiencing wear and tear. Regular inspections and maintenance can help identify potential issues early on and prevent further damage to the spare parts. In conclusion, signs of wear and tear on concrete pump spare parts can include visible damage, increased vibration or noise during operation, reduced performance or efficiency, and increased maintenance requirements. It is important to regularly inspect and maintain these spare parts to ensure their optimal performance and prolong their lifespan.

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of concrete pumped. However, the lifespan of these pipes can vary based on several factors such as the quality of the pipes, the type of concrete being pumped, the pumping pressure, and the maintenance practices followed. Regular inspections, cleaning, and proper storage can help extend the lifespan of concrete pump pipes. Ultimately, it is essential to monitor the wear and tear of the pipes and replace them when necessary to ensure efficient and safe concrete pumping operations.

- Q: What are the indications of a worn-out concrete pump clamp?

- A worn-out concrete pump clamp may exhibit several indications that replacement is necessary. These indications commonly include: 1. Leakage: In the event of leakage around the clamp area while operating the concrete pump, it could signify a worn-out clamp. This leakage may be a result of a faulty seal or gasket, which can no longer establish a secure and tight connection between the pump and the hose. 2. Vibrations and rattling: Excessive vibrations and rattling during the pumping process can be attributed to a worn-out clamp. This can occur when the clamp fails to firmly hold the hose in place, resulting in movement and instability. 3. Difficulty in tightening: If you encounter increasing difficulty in properly tightening the clamp, it may indicate wear-out. Over time, the components of the clamp may deteriorate, making it more challenging to achieve a secure and tight connection. 4. Visual damage: Inspect the clamp for visible signs of damage, such as cracks, dents, or corrosion. These physical damages can compromise the clamp's functionality, potentially leading to leaks or instability. 5. Excessive wear and tear: If you have been utilizing the same concrete pump clamp for an extended period without replacement, it is advisable to regularly inspect it for signs of excessive wear and tear. This may include worn-out or missing bolts, a deformed clamp body, or any other visible signs of deterioration. Promptly addressing any indications of a worn-out concrete pump clamp is crucial to ensure the safety and efficiency of pumping operations. If any of these signs are observed, it is recommended to seek professional consultation or replace the clamp to prevent potential accidents or disruptions in the concrete pumping process.

- Q: What are the different types of concrete pump control system sensors?

- There are several different types of sensors used in concrete pump control systems to ensure smooth and efficient operation. These sensors are designed to monitor various aspects of the pump's performance and provide real-time feedback to the control system. Some of the common types of sensors used in concrete pump control systems include: 1. Pressure Sensors: These sensors are used to measure the pressure of the concrete being pumped. They are typically installed in the discharge line and help to ensure that the pump is operating within the desired pressure range. Pressure sensors are crucial in preventing over-pressurization and potential damage to the pump or pipeline. 2. Flow Sensors: Flow sensors are employed to measure the flow rate of the concrete. By monitoring the volume of concrete passing through the system per unit of time, these sensors enable the control system to regulate the speed and output of the pump accordingly. Flow sensors help in maintaining a consistent and controlled flow of concrete during pumping operations. 3. Level Sensors: Level sensors are utilized to monitor the level of concrete in the hopper or storage tank. These sensors provide information to the control system about the concrete volume, ensuring that the pump is not running dry or becoming overloaded. By maintaining the appropriate level of concrete in the hopper, level sensors help to prevent pump cavitation or blockages. 4. Proximity Sensors: Proximity sensors are used to detect the position of various moving parts in the pump system, such as the boom or outriggers. They provide feedback to the control system, ensuring that the pump operates safely and avoids any potential collisions or obstructions. Proximity sensors play a crucial role in preventing accidents and protecting both the equipment and personnel. 5. Temperature Sensors: Temperature sensors are employed to monitor the temperature of the concrete mix. These sensors help to ensure that the concrete remains within the desired temperature range during pumping, as extreme temperatures can affect the workability and curing process. By maintaining the optimal concrete temperature, temperature sensors contribute to the quality of the final product. Overall, these sensors work together to provide precise and reliable feedback to the control system, allowing for efficient and safe operation of the concrete pump. By continuously monitoring and adjusting various parameters, the sensors help to optimize pumping performance and enhance the overall productivity of concrete placement projects.

- Q: How can a damaged concrete pump piston affect the pumping efficiency?

- A damaged concrete pump piston can significantly affect the pumping efficiency by compromising the seal between the piston and cylinder. This can lead to leakages and loss of pressure, resulting in reduced pumping force and efficiency. Additionally, a damaged piston can cause irregular movements and vibrations, leading to instability and potential damage to other components of the pump. Overall, a damaged concrete pump piston can hinder the smooth flow of concrete, decrease output, and require more energy to operate, ultimately affecting the pumping efficiency.

- Q: What are the signs of a worn-out concrete pump piston?

- There are multiple indicators that can suggest a worn-out concrete pump piston. Initially, a decrease in output or performance may signify this issue. Reduced pumping pressure or slower pumping speed can be observed as a result of this decline in performance. Another indication of a worn-out piston in a concrete pump is increased leakage. If you notice an excessive amount of hydraulic oil or water leaking from the pump, it could be an indication that the piston is no longer effectively sealing. This leakage can also lead to contamination of the hydraulic fluid, which can cause additional harm to the pump components. Furthermore, an irregular concrete flow can be caused by a worn-out piston. If you notice inconsistent and uneven delivery of concrete, such as pulsating or surging flow, it may be due to an uneven wear pattern on the piston. This can have a detrimental effect on the quality of the concrete and the overall efficiency of the pumping operation. Additionally, excessive vibration and noise during the pumping process can also suggest a worn-out piston. Vibrations may occur as a result of the piston not moving smoothly within the cylinder, leading to friction and noise. These vibrations and noises can also indicate other underlying problems with the pump, so it is important to address them promptly. Finally, a visual inspection can provide valuable information regarding the condition of the concrete pump piston. Physical damage, such as cracks or excessive wear on the piston surface, are clear indications of a worn-out piston. These damages can be caused by abrasive materials or harsh operating conditions. In conclusion, if you observe any of these signs or suspect that your concrete pump piston is worn-out, it is crucial to have it inspected and replaced by a professional. Timely maintenance and replacement of worn-out pistons can prevent further damage to the pump and ensure a smooth and efficient operation.

Send your message to us

Tungsten Carbide Zoomlion Spectacle Plate DN230

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords