3M Welded Delivery Pipe for Sany Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Welded Delivery Pipe for Sany Concrete Pump

1. Structure of 3M Welded Delivery Pipe for Sany Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Welded Delivery Pipe for Sany Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

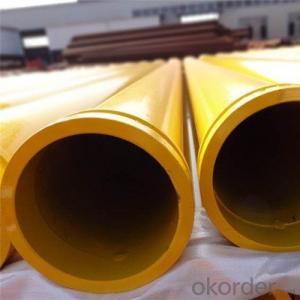

3. 3M Welded Delivery Pipe for Sany Concrete Pump Images

4. 3M Welded Delivery Pipe for Sany Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: How do I properly maintain and replace hydraulic hoses in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic hoses in concrete pump spare parts is crucial to ensure the smooth functioning and longevity of your equipment. Here are some steps you can follow to maintain and replace hydraulic hoses effectively: 1. Regular Inspection: Conduct regular visual inspections of the hoses to identify any signs of wear, damage, or leaks. Look for bulges, cracks, abrasions, or fraying at the ends of the hoses. Pay attention to fittings, connections, and bends in the hose as these areas are prone to damage. 2. Preventative Maintenance: Implement a preventive maintenance schedule to reduce the chances of unexpected hose failure. This includes cleaning the hoses regularly to remove dirt, debris, and concrete residues that may cause abrasion or clogging. Use a mild detergent and water to clean the hoses, and ensure they are thoroughly dried before use. 3. Proper Storage: When not in use, store hydraulic hoses in a clean, dry, and temperature-controlled environment. Protect them from direct sunlight, extreme temperatures, and chemicals, as these factors can degrade the hoses over time. 4. Correct Handling: Always handle hydraulic hoses with care to prevent damage. Avoid dragging them on rough surfaces or sharp edges that can cause cuts or abrasions. Do not allow the hoses to kink or twist excessively, as this can weaken the internal structure. 5. Timely Replacement: Replace hydraulic hoses as soon as you notice signs of wear, damage, or leaks. Do not wait for hose failure, as it can lead to costly downtime and potential safety hazards. Follow the manufacturer's recommendations for the replacement interval, which may vary based on the type of hose and its usage. 6. Use Quality Replacement Hoses: When replacing hydraulic hoses, ensure that you use high-quality hoses that are compatible with your concrete pump. Choose hoses that meet industry standards and specifications, as they are designed to withstand the demanding conditions of concrete pumping. 7. Proper Installation: Properly install the replacement hoses, ensuring that they are correctly routed and securely connected to the fittings. Use appropriate tools and techniques to tighten the fittings, avoiding over-tightening that can damage the hose or fittings. 8. Regular Training: Provide regular training to your staff on proper maintenance, inspection, and replacement procedures for hydraulic hoses. This will enhance their knowledge and skills, reducing the risks of improper handling or installation. By following these steps, you can effectively maintain and replace hydraulic hoses in concrete pump spare parts, ensuring the safety and efficiency of your equipment. Remember to consult the manufacturer's guidelines and seek professional assistance whenever necessary.

- Q: How to diagnose the blockage in the inlet of concrete pump?

- If it doesn't work, you'll have to clean it up manually and rule it out.

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of pumped concrete, depending on various factors such as pump usage, maintenance, and the type of concrete being pumped.

- Q: What are the different types of concrete pump hydraulic filters?

- Construction projects commonly utilize various types of concrete pump hydraulic filters. These filters are crucial for ensuring the hydraulic system's smooth operation and longevity. 1. Suction filters, located at the hydraulic pump's intake side, play a vital role in removing larger particles and debris from the hydraulic oil. They prevent contaminants from entering the pump and causing harm to its components. 2. Positioned on the return line, return line filters are designed to eliminate smaller particles and contaminants from the hydraulic oil before it is returned to the reservoir. By maintaining oil cleanliness, they prevent system wear and tear. 3. Pressure line filters, typically installed after the hydraulic pump on the high-pressure side, remove fine particles and contaminants from the oil. Their purpose is to guarantee the valves, cylinders, and other hydraulic components work smoothly. 4. In-tank filters are submerged in the hydraulic oil reservoir to filter the oil as it circulates through the tank. They effectively eliminate larger particles and contaminants settled at the bottom of the reservoir. 5. Magnetic filters attract and remove metallic particles, such as iron filings and metal shavings, from the hydraulic oil. They are highly effective in capturing ferrous contaminants. 6. Breather filters, installed on the breather vent of the hydraulic oil reservoir, maintain the cleanliness and integrity of the hydraulic oil by preventing dust, dirt, and moisture from entering the system. Regular inspection and replacement of these hydraulic filters are crucial for optimal performance and longevity of the concrete pump's hydraulic system. Neglecting this maintenance can lead to increased wear and tear, decreased efficiency, and potential damage to the pump and its components.

- Q: What is the purpose of a concrete pump hopper grate?

- The purpose of a concrete pump hopper grate is to filter out any large debris or aggregates from the concrete mixture as it is being pumped into the hopper. It helps to ensure a smooth and consistent flow of concrete, preventing any blockages or clogs in the pump system.

- Q: How long does a concrete pump piston typically last?

- A concrete pump piston typically lasts between 20,000 to 60,000 pumping hours, depending on factors such as maintenance, usage, and the quality of the pump.

- Q: How much do concrete pump spare parts typically cost?

- The cost of concrete pump spare parts can vary significantly depending on the specific part needed, its brand, quality, and availability. It is recommended to contact suppliers or manufacturers for accurate and up-to-date pricing information.

- Q: Why would the plugging concrete pump pipe

- When it is found that a bucket of concrete slump is very small, can not pump, should be in time the concrete from the bottom of the hopper release, if seeking trouble, forced pumping, easy to cause blockage. Avoid stirring with water in the hopper

- Q: What are the advantages of using tungsten carbide components in concrete pump spare parts?

- There are several advantages of using tungsten carbide components in concrete pump spare parts. Firstly, tungsten carbide is an extremely hard and durable material, which ensures longer lifespan and increased wear resistance of the components. This means reduced maintenance and replacement costs in the long run. Additionally, tungsten carbide has excellent corrosion resistance, making it suitable for use in harsh and corrosive environments commonly found in concrete pumping applications. Furthermore, tungsten carbide components offer superior strength and toughness, enabling them to withstand high-pressure and heavy-duty operations without compromising performance. Overall, the use of tungsten carbide in concrete pump spare parts leads to improved efficiency, reliability, and cost-effectiveness in concrete pumping operations.

- Q: How can one source reliable suppliers for concrete pump spare parts?

- One can source reliable suppliers for concrete pump spare parts by following a few steps. Firstly, it is important to conduct thorough research on potential suppliers. This can be done by searching online directories, industry forums, and marketplaces dedicated to construction equipment and spare parts. Reading customer reviews and ratings can provide valuable insights into the reliability and quality of the suppliers. Secondly, it is advisable to reach out to industry professionals and experts who have experience in the concrete pump industry. They can provide recommendations and references for reliable suppliers they have worked with in the past. Additionally, attending trade shows and exhibitions related to the construction industry can be a great way to connect with suppliers and evaluate their product offerings in person. This allows for direct communication and the opportunity to assess the reliability and quality of their spare parts. Moreover, it is essential to request samples or product catalogs from potential suppliers to ensure that the spare parts meet the required specifications and quality standards. This can help in assessing the reliability of the suppliers and the compatibility of their products with the concrete pump. Furthermore, conducting background checks on the suppliers is crucial. Verifying their credentials, certifications, and licenses can provide assurance of their reliability and professionalism. It is also beneficial to inquire about their manufacturing processes and quality control measures to ensure the consistency and durability of the spare parts. Lastly, comparing prices, warranties, and after-sales services offered by different suppliers can help in making an informed decision. It is important to strike a balance between the cost and the reliability of the suppliers to ensure a long-term and fruitful partnership. By following these steps and taking the time to thoroughly evaluate and research potential suppliers, one can source reliable suppliers for concrete pump spare parts and ensure the smooth operation and maintenance of their equipment.

Send your message to us

3M Welded Delivery Pipe for Sany Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords