3M Welded Delivery Pipe for Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Welded Delivery Pipe for Schwing Concrete Pump

1. Structure of 3M Welded Delivery Pipe for Schwing Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Welded Delivery Pipe for Schwing Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

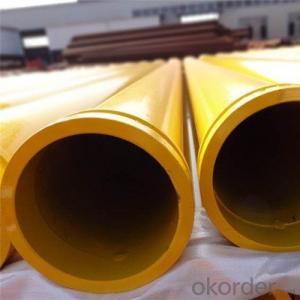

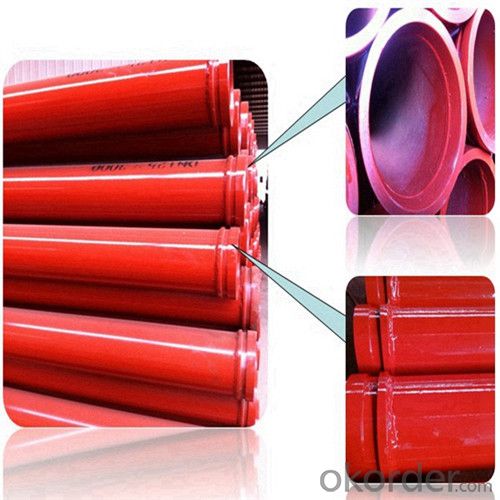

3. 3M Welded Delivery Pipe for Schwing Concrete Pump Images

4. 3M Welded Delivery Pipe for Schwing Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Can concrete pump spare parts be pre-assembled or pre-tested before installation?

- Concrete pump spare parts can undergo pre-assembly and pre-testing prior to installation. This allows for quality control measures to be implemented before the actual installation takes place, ensuring that any defects or issues with the parts can be identified and resolved before they are put into the concrete pump. Furthermore, pre-testing the spare parts guarantees their functionality and compatibility with the pump system, enabling any necessary adjustments or modifications to be made in advance. By engaging in these practices, the risk of complications during the installation process is reduced, resulting in a smooth and efficient operation of the pump system.

- Q: How often should hopper screens be cleaned or replaced?

- Hopper screens should be cleaned or replaced regularly, ideally on a quarterly basis, to ensure proper functioning and prevent clogging or damage to the equipment.

- Q: How can a faulty gearbox affect the pump's performance?

- A faulty gearbox can significantly impact the performance of a pump. The gearbox is responsible for transmitting power from the motor to the pump, and any dysfunction in this component can lead to various issues. Firstly, a faulty gearbox can cause a decrease in the pump's efficiency. The gearbox is designed to regulate the speed and torque of the pump, ensuring that it operates at optimal levels. If the gearbox is faulty, it may not be able to provide the necessary power to the pump, resulting in reduced performance and lower efficiency. This can lead to increased energy consumption and decreased overall productivity. Additionally, a faulty gearbox can cause the pump to experience excessive vibration and noise. A properly functioning gearbox helps to absorb and distribute the forces generated during operation, reducing vibration and noise levels. However, if the gearbox is faulty, it may fail to dampen these forces adequately, resulting in increased vibrations and noise. This can not only affect the pump's performance but also lead to premature wear and tear of other components, further impacting its overall efficiency. Furthermore, a faulty gearbox can result in inconsistent flow rates and pressure fluctuations. The gearbox plays a crucial role in controlling the speed and output of the pump. If the gearbox is malfunctioning, it may not be able to maintain a consistent flow rate or pressure, leading to fluctuations in the pump's performance. Inconsistent flow rates can disrupt processes that rely on precise volumes or pressures, causing inefficiencies and potential damage to downstream equipment. In conclusion, a faulty gearbox can have a detrimental effect on the performance of a pump. It can lead to decreased efficiency, increased vibrations and noise, as well as inconsistent flow rates and pressure fluctuations. Therefore, regular maintenance and prompt repair or replacement of faulty gearboxes are essential to ensure the optimal functioning of pumps and prevent any further damage or operational issues.

- Q: How often should a concrete pump spectacle plate be replaced?

- The frequency of replacing a concrete pump spectacle plate depends on various factors such as usage intensity, maintenance practices, and the condition of the plate. However, as a general guideline, it is recommended to inspect and potentially replace the spectacle plate every 500 to 1000 hours of operation or sooner if signs of wear or damage are observed. Regular inspections and timely replacements help ensure optimal performance and prevent any potential safety risks.

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: How do I troubleshoot issues related to concrete pump spare parts control systems?

- To troubleshoot issues related to concrete pump spare parts control systems, you can follow these steps: 1. Start by checking the power supply and connections to ensure there are no loose or damaged wires. 2. Verify that the control system is properly calibrated and programmed according to the manufacturer's instructions. 3. Inspect the control panel for any visible signs of damage, such as burnt components or water ingress. 4. Use a multimeter to test the voltage and continuity of different control system components, such as sensors, switches, and relays. 5. Consult the system's user manual or contact the manufacturer for any specific troubleshooting steps or error code interpretations. 6. If the issue persists, consider contacting a professional technician or the manufacturer's customer support for further assistance.

- Q: How can the concrete pump pipe be cleaned?

- The pipeline shall be provided with a stop valve, and the stop plate shall be inserted to prevent the vertical or upward tilting of the concrete in the pipe

- Q: What are the potential risks associated with the installation and replacement of concrete pump spare parts?

- The installation and replacement of concrete pump spare parts come with various potential risks. Improper installation is a key risk, as it can cause leaks, reduced performance, and even equipment failure. This not only leads to expensive repairs but also poses a safety threat to workers and those nearby. Another risk is the use of counterfeit or low-quality spare parts. These parts may not meet the necessary standards, compromising the integrity and functionality of the concrete pump. This increases the likelihood of equipment failure and accidents. Moreover, the installation and replacement process may involve operating heavy machinery like cranes or forklifts, which can be dangerous if not done correctly. Inadequate precautions can result in accidents, injuries, or damage to the equipment or surrounding structures. Additionally, concrete pump spare parts may contain hazardous materials or substances. Workers must be aware of the risks associated with handling and disposing of these materials, such as exposure to harmful chemicals or environmental contamination. Lastly, there is a risk of delays and downtime during the installation and replacement process. If spare parts are not readily available or compatibility issues arise, equipment may be inoperable for extended periods. This can cause project delays, increased costs, and potential financial losses. To mitigate these risks, it is crucial to provide proper training and supervision to workers involved in the installation and replacement of concrete pump spare parts. Using genuine and high-quality spare parts from reputable suppliers can also reduce the risk of equipment failure. Regular inspections, maintenance, and adherence to safety protocols are essential to minimize potential risks associated with this process.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Yes, spare parts for concrete pump boom arms and pipes are available. Many manufacturers and suppliers offer a wide range of spare parts specifically designed for concrete pump boom arms and pipes. These spare parts can be easily found and purchased from authorized dealers or online stores. It is important to ensure that you provide accurate specifications and details of your concrete pump model to find the correct spare parts for replacement or repair.

- Q: How long do concrete pump spare parts typically last?

- There are several factors that can affect the lifespan of concrete pump spare parts. Generally, high-quality parts can last between 1,000 and 2,500 working hours. However, this estimate can be influenced by factors such as the type and brand of the spare parts, how often they are used, the quality of maintenance they receive, and the working conditions in which the concrete pump operates. Some spare parts for concrete pumps may have a shorter lifespan due to the wear and tear they experience during operation. For example, wear parts like rubber seals, pistons, and wear plates are more prone to damage and may need to be replaced more frequently. On the other hand, structural components like pipes, hoses, and hydraulic cylinders tend to last longer. Extending the lifespan of concrete pump spare parts relies on proper maintenance and regular inspections. Adequate lubrication, cleaning, and timely replacement of worn-out parts can significantly increase their durability. Additionally, the expertise and skill of the operator also play a role in the lifespan of the spare parts, as improper use or mishandling can lead to premature failure. While it is possible to estimate the average lifespan of concrete pump spare parts, it is important to consider the specific circumstances and conditions in which the concrete pump operates to determine their actual longevity. Regular maintenance, the use of high-quality parts, and proper usage will ultimately help maximize the lifespan of concrete pump spare parts.

Send your message to us

3M Welded Delivery Pipe for Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords