High Quality Sany Spectacle Wear Plate Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

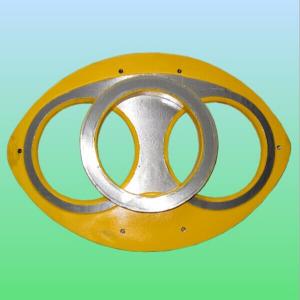

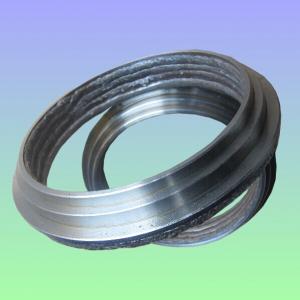

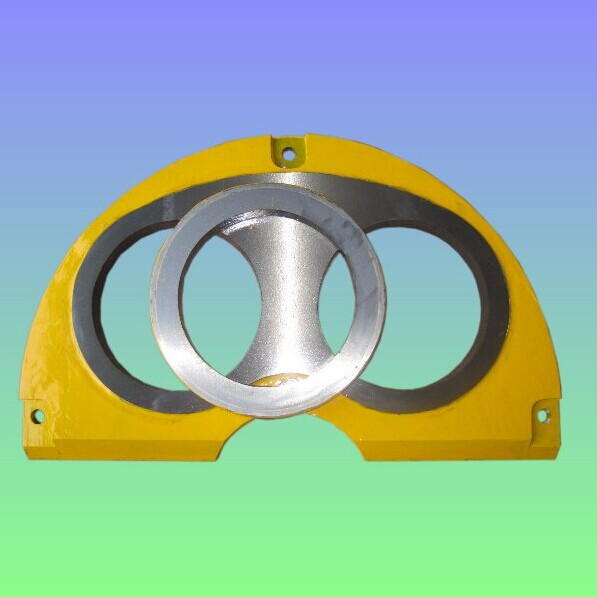

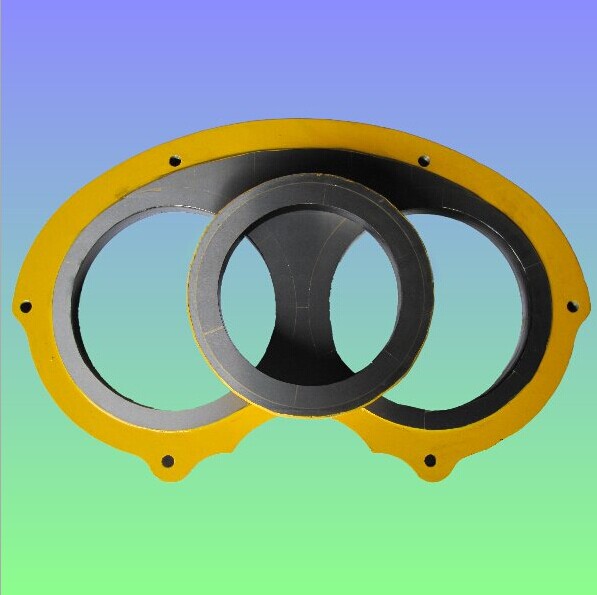

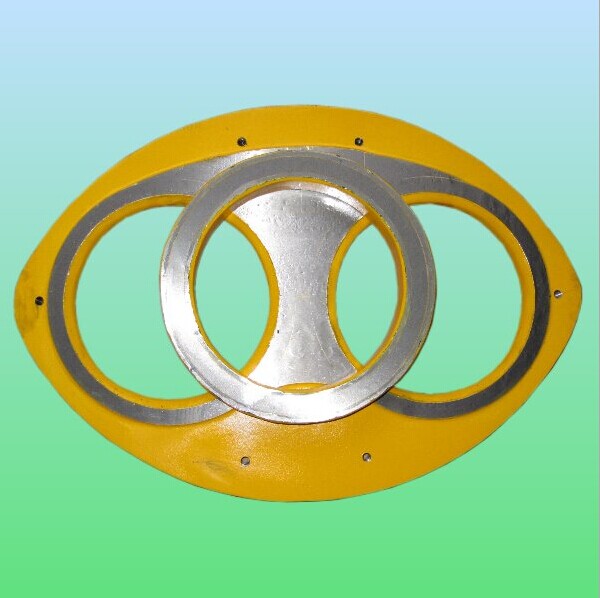

Product Name: High Quality Sany Spectacle Wear Plate Tungsten Carbide

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted Sany Pump

Notes: total series of High Quality Sany Spectacle Wear Plate Tungsten Carbide for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our High Quality Sany Spectacle Wear Plate Tungsten Carbide have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs High Quality Sany Spectacle Wear Plate Tungsten Carbide put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some High Quality Sany Spectacle Wear Plate Tungsten Carbide according to customers request?

A4: Yes, we can produce High Quality Sany Spectacle Wear Plate Tungsten Carbide according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: Can I get spare parts for both concrete pumps with and without remote control systems?

- Yes, it is possible to get spare parts for both concrete pumps with and without remote control systems. Many manufacturers and suppliers of construction equipment offer spare parts for various models and types of concrete pumps. Whether your pump has a remote control system or not, you can typically find replacement parts such as valves, cylinders, hoses, pistons, and other components from reputable suppliers. It is important to ensure that you provide the correct specifications and model details when ordering spare parts to ensure compatibility with your specific concrete pump.

- Q: Are there any specific guidelines for the installation of wear plates or cutting rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of wear plates and cutting rings in concrete pump spare parts. These guidelines typically include instructions on proper alignment, torque specifications for bolts, and the use of appropriate lubricants. Following these guidelines ensures optimal performance and longevity of the wear plates and cutting rings in concrete pump spare parts.

- Q: Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts. Here are some general guidelines to follow: 1. Safety precautions: Always ensure that the concrete pump is turned off and depressurized before attempting to install any seal kits or O-rings. Wear appropriate safety gear, such as gloves and goggles, to protect yourself during the installation process. 2. Preparation: Thoroughly clean the area where the seal kits or O-rings will be installed. Remove any debris or old seal remnants to ensure a clean and smooth surface for installation. 3. Inspection: Before installing new seal kits or O-rings, inspect them for any defects or damage. If any issues are found, replace the faulty parts with new ones. 4. Lubrication: Apply a small amount of compatible lubricant or hydraulic oil to the seal kits or O-rings to aid in their installation and prevent damage during the process. Be sure to use a lubricant that is compatible with the materials used in the seal kits or O-rings. 5. Proper alignment: Carefully align the seal kits or O-rings with their respective grooves or seating areas in the concrete pump. Ensure that they are properly seated and positioned before proceeding. 6. Correct installation technique: Use the appropriate tools and techniques to install the seal kits or O-rings. Avoid excessive force or bending, as this can lead to damage or improper sealing. 7. Testing: After the installation is complete, test the concrete pump to ensure that the seal kits or O-rings are functioning properly. Check for any leaks or abnormal behavior during operation. 8. Regular maintenance: Once the seal kits or O-rings are installed, it is important to regularly inspect and maintain them to ensure their longevity and optimal performance. Follow the manufacturer's recommended maintenance schedule and guidelines for best results. It is important to note that these guidelines are general in nature and may vary depending on the specific make and model of the concrete pump. Therefore, it is always recommended to consult the manufacturer's instructions and guidelines for the particular seal kits or O-rings being installed.

- Q: How do I find the right part number for a specific concrete pump spare part?

- To find the right part number for a specific concrete pump spare part, there are a few steps you can follow: 1. Identify the specific part you need: First, determine the exact part you are looking for. This could be a specific component or a replacement part for a particular area of the concrete pump. 2. Consult the equipment manual: Check the equipment manual or documentation that came with the concrete pump. The manual often includes a parts list or diagram, which can help you identify the part number you need. 3. Contact the manufacturer or supplier: Reach out to the manufacturer or supplier of the concrete pump to inquire about the specific part you require. Provide them with the make, model, and serial number of the pump, as well as a detailed description or photograph of the part if possible. They should be able to provide you with the correct part number and any additional information you may need. 4. Use online resources: Utilize online resources such as manufacturer websites, spare parts catalogs, or specialized equipment platforms. These platforms often have search functions where you can input the make and model of the concrete pump to find the corresponding part numbers. 5. Seek assistance from industry experts: If you are still unable to find the right part number, consider reaching out to industry experts or professionals who specialize in concrete pump equipment. They may have the knowledge and experience to help you identify the correct part number based on your specific needs. Remember to double-check the part number provided by the manufacturer or supplier to ensure accuracy before making any purchases. Additionally, it is advisable to keep a record of the part number for future reference in case you need to reorder or replace the part again.

- Q: How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- Hopper grate pin retainers in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure their proper functioning and prevent any potential issues. However, the frequency of inspections may vary depending on the specific conditions of use and the manufacturer's recommendations. During these inspections, it is essential to check for any signs of wear, damage, or corrosion on the hopper grate pin retainers. If any of these issues are detected, immediate replacement is necessary to maintain the efficiency and safety of the concrete pump. Additionally, it is crucial to adhere to the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may recommend replacing them after a certain number of operating hours, while others may suggest replacement based on the visual condition during inspections. Regular inspections and timely replacement of hopper grate pin retainers are crucial to prevent potential malfunctions or accidents during concrete pumping operations. It is always recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines regarding the inspection and replacement intervals for hopper grate pin retainers.

- Q: What are the common challenges in sourcing spare parts for stationary concrete pumps?

- Sourcing spare parts for stationary concrete pumps can present various common obstacles. Firstly, availability poses a significant challenge. Depending on the concrete pump's brand and model, locating the exact spare parts needed can prove difficult. Some manufacturers lack a widespread distribution network, making it challenging to promptly locate the required spare parts. This difficulty is intensified if the concrete pump is an older model or if the manufacturer has ceased production. Another significant challenge is cost. Spare parts for stationary concrete pumps can be pricey, particularly when sourced directly from the manufacturer. Alongside the initial cost, additional expenses like shipping, customs duties, and taxes further escalate the overall cost of acquiring spare parts. Ensuring quality assurance is a crucial aspect when sourcing spare parts. It is vital to verify that the sourced spare parts are of high quality and compatible with the specific make and model of the concrete pump. Inferior spare parts can result in performance issues, breakdowns, and potential safety hazards, detrimentally impacting the overall efficiency and lifespan of the concrete pump. Timing also plays a pivotal role in spare parts sourcing. When a concrete pump malfunctions, it can cause delays in construction projects, leading to extra expenses and potential penalties. Therefore, swiftly and efficiently finding spare parts is essential to minimize downtime and ensure smooth operations. Additionally, language and communication barriers can present challenges. If the spare parts manufacturer or supplier is situated in a different country or speaks a different language, effective communication can be problematic. This can lead to misunderstandings, delays, and difficulties in accurately conveying specific spare parts requirements. To overcome these challenges, it is advisable to collaborate with reputable suppliers specializing in concrete pump spare parts. These suppliers often maintain a vast inventory of spare parts, ensuring availability and reducing the risk of delays. Furthermore, establishing strong relationships with local distributors or authorized service centers can streamline access to spare parts and technical support. Regular maintenance and proactive planning can also help mitigate the challenges of sourcing spare parts for stationary concrete pumps. Maintaining an inventory of essential spare parts and components can minimize downtime and ensure smooth operations.

- Q: Why would the plugging concrete pump pipe

- When pumping, the choice of speed is critical, operators can not blindly map fast, sometimes more haste, less speed. When pumping for the first time, due to the large resistance of the pipeline, the pump should be pumped at low speed. After the pump is normal, the pump speed can be increased properly

- Q: Can I get spare parts for both single-cylinder and multi-cylinder concrete pumps?

- Spare parts for both single-cylinder and multi-cylinder concrete pumps are readily available. Various manufacturers and suppliers offer a wide range of spare parts for different concrete pump types, including single-cylinder and multi-cylinder models. These spare parts comprise hydraulic cylinders, pistons, seals, valves, hoses, and other crucial components that may require replacement due to wear and tear or damage. To ensure compatibility and availability, it is vital to contact the concrete pump's specific manufacturer or supplier and inquire about the spare parts suitable for your particular model.

- Q: How often should concrete pump water pumps be inspected and replaced?

- The frequency of inspection and replacement for concrete pump water pumps depends on several factors including the workload, operating conditions, and maintenance practices. Generally, it is recommended to inspect the water pump at least once a month to ensure its proper functioning. During the inspection, it is important to check for any leaks, unusual noises, or signs of wear and tear. If any issues are identified, immediate action should be taken to resolve them, such as repairing or replacing damaged parts. As for replacement, it is difficult to provide an exact timeframe as it varies depending on the quality of the pump, the intensity of use, and the level of maintenance. However, a general guideline is to consider replacing the water pump every 1-2 years for heavy usage or every 3-5 years for moderate usage. Regular maintenance, such as cleaning and lubricating the pump, can extend its lifespan and minimize the need for frequent replacements. It is important to note that these recommendations are general guidelines and may vary depending on the specific manufacturer's instructions, industry standards, and local regulations. It is advisable to consult the manufacturer's guidelines and seek professional advice from experts in the field to determine the appropriate inspection and replacement schedule for concrete pump water pumps in your specific circumstances.

- Q: How often should concrete pump S valves be inspected and replaced?

- Concrete pump S valves should be inspected regularly, ideally every 500 hours of operation or at least once a year. However, the replacement of S valves will depend on various factors such as the quality of the concrete being pumped, the frequency of use, and the overall condition of the valve. It is recommended to consult the manufacturer's guidelines and seek professional advice to determine the specific timing of S valve replacement.

Send your message to us

High Quality Sany Spectacle Wear Plate Tungsten Carbide

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords