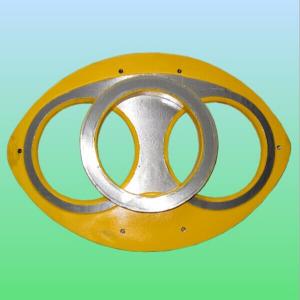

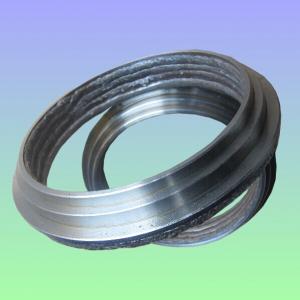

High Quality Tungsten Carbide Cifa Spectacle Wear Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: High Quality Tungsten Carbide Cifa Spectacle Wear Plate

1. Specification

1. Material: Plate body S35C steel, tungsten carbide E5 grade ,

2. Lifetime: 30,000~80,000cbm

3. HRA≥86

4. Germany Welding rod used for hardfacing

5. tensile strength ≥ 2500 N/mm2

6. Application: trailer and trunk mounted CIFA Pump

Notes: total series of Concrete Pump Spectacle Wear Plate and Cutting Ring for different brand concrete pump (PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO,Niigata Etc) available from us.

2. Application

Our High Quality Tungsten Carbide Cifa Spectacle Wear Plate have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package

Every 60pcs High Quality Tungsten Carbide Cifa Spectacle Wear Plate put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some High Quality Tungsten Carbide Cifa Spectacle Wear Plate according to customers request?

A4: Yes, we can produce High Quality Tungsten Carbide Cifa Spectacle Wear Plate according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: Can I get spare parts for both concrete pumps with and without pressure washers?

- Yes, spare parts are available for both concrete pumps with and without pressure washers.

- Q: What are the signs of a damaged concrete pump cylinder?

- Some signs of a damaged concrete pump cylinder can include reduced pumping performance, loss of pressure, leaks or drips around the cylinder, abnormal noises during operation, uneven wear or scoring on the cylinder wall, and visible cracks or deformations on the cylinder body.

- Q: How can one determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts?

- To determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts, one can refer to the manufacturer's recommendations and specifications. These guidelines will outline the appropriate viscosity grade and temperature range for optimal performance and longevity of the spare parts. It is important to follow these recommendations to ensure efficient lubrication and protection of the concrete pump components. Additionally, consulting with industry experts or conducting research on lubrication requirements specific to concrete pump spare parts can also provide valuable insights for determining the correct viscosity and temperature range.

- Q: How often should hydraulic accumulator bladders be inspected or replaced in a concrete pump?

- Hydraulic accumulator bladders in a concrete pump should be inspected regularly, ideally every 6-12 months, to ensure they are in good condition and functioning properly. However, the frequency of replacement depends on various factors such as the pump's usage, operating conditions, and manufacturer's recommendations. It is best to consult the concrete pump's manual or reach out to the manufacturer for specific guidance on when to replace the bladders.

- Q: How often should agitator shaft seals be replaced in a concrete pump?

- Several factors influence the frequency of agitator shaft seal replacement in a concrete pump. These factors include the type and quality of the seal, the pump's operational conditions, and the user's maintenance practices. However, as a general rule, it is advisable to inspect and replace agitator shaft seals every 500 to 1,000 operating hours or annually, whichever comes first. Regular inspection of the seals is essential. This is to detect any signs of wear, leakage, or damage. If any of these issues are found, immediate seal replacement is necessary. This is to prevent further damage to the pump and ensure optimal performance. It is also important to adhere to the manufacturer's instructions and recommendations for seal replacement. These instructions may be specific to the pump model and seal type. Proper maintenance practices, such as regular cleaning and lubrication of the seals, can help prolong their lifespan. This can also reduce the need for frequent replacements. It is important to remember that failure to replace worn or damaged agitator shaft seals in a timely manner can result in increased downtime, decreased efficiency, and potential damage to other pump components. Therefore, regular inspection and replacement of agitator shaft seals should be prioritized to ensure the smooth operation and longevity of the concrete pump.

- Q: What is the importance of a concrete pump control valve?

- The operation of a concrete pump heavily relies on the presence of a control valve, which plays a vital role. This crucial component allows for the accurate and efficient management of concrete flow and pressure. To grasp the significance of a concrete pump control valve, one must consider its various functions. Firstly, it serves to regulate the movement of concrete from the hopper to the pumping cylinders. Through manipulation of this valve, operators can adjust the flow rate to meet the specific demands of the project. This ensures that the appropriate amount of concrete is pumped, preventing wastage and optimizing productivity. Secondly, the control valve facilitates precise control of pressure within the pumping cylinders. By making adjustments to the valve, operators can increase or decrease pressure levels, maintaining a consistent and steady concrete flow. This ability is crucial in preventing blockages or clogs within the concrete pump system, which can lead to costly downtime and repairs. Moreover, the control valve enables operators to switch between different pumping modes, such as high-pressure pumping or low-pressure spraying. This versatility allows for the efficient completion of a wide range of concrete pumping tasks, from pouring foundations to applying decorative concrete finishes. In addition to its functional significance, a concrete pump control valve also contributes to the safety of the pumping operation. It empowers operators to halt or reverse the flow of concrete swiftly in the event of emergencies or equipment malfunctions. This feature ensures that potential hazards are promptly addressed, minimizing the risk of accidents and injuries. Overall, the importance of a concrete pump control valve lies in its capacity to provide precise control over concrete flow and pressure during pumping operations. It guarantees efficiency, productivity, versatility, and safety, establishing it as an indispensable component of any concrete pumping system.

- Q: How can a faulty oil cooler affect the pump's hydraulic system?

- The pump's hydraulic system can be affected in multiple ways by a defective oil cooler. Firstly, it is the responsibility of the oil cooler to maintain the hydraulic oil at an optimal temperature. If the oil cooler is flawed and fails to cool the oil efficiently, the hydraulic oil may become overheated. This can result in a decrease in the oil's viscosity, causing it to lose its lubricating properties. Consequently, the pump's moving parts may experience heightened friction and wear, leading to reduced efficiency and potential damage to the pump itself. Secondly, a defective oil cooler can lead to inadequate cooling of the hydraulic oil, resulting in elevated temperatures within the system. Elevated temperatures can cause the oil to oxidize, leading to the formation of sludge and varnish deposits. These deposits can obstruct the smooth operation of the hydraulic system, including the pump, valves, and other components, potentially causing malfunctions. Furthermore, a faulty oil cooler can also cause a decrease in the rate of oil flow. If the oil cooler is not functioning properly, it can restrict the flow of hydraulic oil, reducing the amount of oil available for the pump's operation. This can result in decreased hydraulic pressure, affecting the pump's performance and potentially causing issues such as reduced power output or inadequate operation of hydraulic actuators. In summary, a defective oil cooler can have negative effects on the pump's hydraulic system, including overheating, increased friction and wear, the formation of deposits, and a reduced oil flow rate. It is essential to regularly inspect and maintain the oil cooler to ensure proper functioning and prevent potential damage to the hydraulic system.

- Q: What are the key considerations when purchasing spare parts for a concrete pump?

- When purchasing spare parts for a concrete pump, there are several key considerations that need to be taken into account. These considerations include the compatibility of the spare parts with the specific make and model of the concrete pump, the quality and reliability of the spare parts, the availability of the spare parts, and the cost-effectiveness of the purchase. First and foremost, it is crucial to ensure that the spare parts being purchased are compatible with the concrete pump in question. Concrete pumps come in various makes and models, and each may have specific requirements in terms of spare parts. Therefore, it is essential to carefully match the specifications and requirements of the concrete pump with the spare parts being purchased to ensure proper functionality and performance. The quality and reliability of the spare parts are also vital considerations. Investing in high-quality spare parts can significantly impact the efficiency and longevity of the concrete pump. It is advisable to choose spare parts from reputable manufacturers or suppliers who have a proven track record of producing reliable products. Conducting thorough research and reading customer reviews can help in assessing the quality and reliability of the spare parts. Availability is another important factor to consider when purchasing spare parts for a concrete pump. It is essential to ensure that the spare parts needed are readily available, either from local suppliers or through efficient delivery channels. A delay in obtaining the necessary spare parts can lead to extended downtime and increased costs. Therefore, it is recommended to choose suppliers who have a reliable and efficient distribution network. Cost-effectiveness is also a key consideration when purchasing spare parts. While it is important to prioritize quality and reliability, it is equally important to find spare parts that offer good value for money. Comparing prices from different suppliers and considering the lifespan and potential maintenance costs of the spare parts can help in making a cost-effective decision. It is crucial to strike a balance between cost and quality to ensure the best return on investment. In conclusion, when purchasing spare parts for a concrete pump, it is important to consider compatibility, quality, availability, and cost-effectiveness. By carefully evaluating these key considerations, one can ensure that the spare parts chosen will meet the specific needs of the concrete pump, maintain its performance and reliability, and provide value for money.

- Q: Are there any specific safety considerations when using concrete pump spare parts?

- Concrete pump spare parts must be carefully considered for safety purposes. The first consideration is ensuring compatibility with the specific pump model. Using incompatible parts can lead to malfunctions, risking accidents and injuries. Proper training and knowledge are also crucial. Operators must be trained on installation, maintenance, and replacement of spare parts. They should also follow any safety precautions recommended by the manufacturer. Regular inspection of spare parts is important. Any signs of wear, damage, or deterioration should prompt immediate replacement to prevent accidents or equipment failure. Personal protective equipment (PPE) is essential when working with concrete pump spare parts. This may include goggles, gloves, hard hats, and steel-toed boots. PPE safeguards against hazards like debris, falls, or contact with hazardous substances. Adhering to local regulations and industry standards is advisable. These regulations may outline specific requirements for installation, operation, and maintenance of concrete pump spare parts. By adhering to these safety considerations, operators can minimize the risk of accidents, injuries, and equipment failure when using concrete pump spare parts.

- Q: How do I ensure the reliability of concrete pump spare parts in critical applications?

- To ensure the reliability of concrete pump spare parts in critical applications, there are several steps you can take: 1. Choose a reputable supplier: Research and select a trusted supplier known for providing high-quality concrete pump spare parts. Look for suppliers with a strong track record, positive customer reviews, and certifications that demonstrate their commitment to quality and reliability. 2. Verify product specifications and certifications: Before purchasing any spare parts, carefully review the product specifications and certifications. Ensure that the parts meet the required standards and have undergone rigorous testing to guarantee their reliability in critical applications. 3. Conduct regular maintenance and inspections: Implement a comprehensive maintenance and inspection schedule for your concrete pump and its spare parts. Regularly check for signs of wear, damage, or malfunction. Replace any parts that show signs of deterioration or that no longer meet the required specifications. 4. Use genuine spare parts: Always opt for genuine spare parts that are specifically designed for your concrete pump model. Genuine parts are manufactured to the highest standards and are more likely to provide reliable performance in critical applications compared to generic or counterfeit alternatives. 5. Keep an inventory of critical spare parts: Identify the most critical spare parts that are prone to failure or wear and keep an inventory of these parts on hand. This will minimize downtime in case of unexpected failures and ensure that you can quickly replace any faulty components. 6. Train and educate operators: Provide thorough training to your concrete pump operators on proper handling and maintenance of spare parts. Educate them on the importance of following manufacturer guidelines and best practices to maximize the reliability and longevity of the equipment. 7. Prioritize safety: Safety should always be a top priority in critical applications. Ensure that the spare parts you use are compliant with safety regulations and standards. Regularly assess and update safety protocols to minimize the risk of accidents or equipment failure. By following these steps, you can enhance the reliability of concrete pump spare parts in critical applications, reducing the likelihood of downtime and ensuring the smooth operation of your equipment.

Send your message to us

High Quality Tungsten Carbide Cifa Spectacle Wear Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords