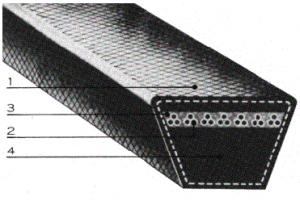

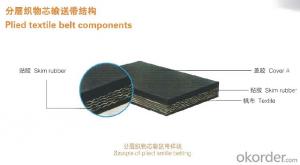

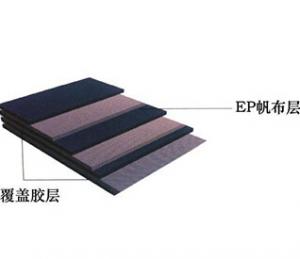

EP belting-Plied textile conveyor belts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

pecifications

conveyor belt system design

1. High modulus

2. High resistance to tension

3. Good through ability

4. Good impact resistance

ep conveyor belt system design

CONVEYOR BELT SYSTEM DESIGN

Features of conveyor belt system design

1) Good elasticity, anti-impact

2) High adhesion, good flexing capacity

3) Good trough ability

4) Higher strength, smaller thickness and weight

5) Good resistance to moisture and heat, corrosion resistant

6) Good wear ability and long service life

Technical Index of conveyor belt system design

Main technical Data | ||||||

Total Tensile Strength(N/mm) | Fabric Type | Top Cover Thickness(mm) | Bottom Cover Thickness(mm) | |||

200-800 | EP100 | 3.0 | 4.5 | 6.0 | 1.5 | 3.0 |

315-1250 | EP150 | 3.0 | 4.5 | 6.0 | 1.5 | 3.0 |

400-1500 | EP200 | 3.0 | 4.5 | 6.0 | 1.5 | 3.0 |

500-2000 | EP250 | 3.0 | 4.5 | 6.0 | 1.5 | 3.0 |

500-2000 | EP300 | 3.0 | 4.5 | 6.0 | 1.5 | 3.0 |

630-2500 | EP400 | 3.0 | 4.5 | 6.0 | 1.5 | 3.0 |

Adhesion between Layers(DIN22102) Unit: N/mm | |||

Item | Adhesion between Fabrics(N/mm) | Adhesion between Rubber and Fabric(N/mm) | |

Cover≤1.5mm | Cover>1.5mm | ||

Max.≤ | 20 | 20 | 20 |

Aaverage≥ | 5 | 3.5 | 4.5 |

Min.≤ | 4 | 2.5 | 3.5 |

Item | Unit | Rubber Grade | |||

W | X | Y | Z | ||

Tensile Strength≥ | N/mm² | 18 | 25 | 18 | 15 |

Elongation at Break≥ | % | 400 | 450 | 400 | 350 |

Abrasion≤ | mm³ | 90 | 120 | 150 | 250 |

- Q: Why is the watch of rubber band more expensive than resin?

- PS: rubber contains a variety of ingredients, a pungent odor, some of which may have an impact on human health, so generally contact the skin and long-term contact will use silicone.

- Q: Why are the engines almost all rubber belts?

- The main reason for the belt is to prevent overload, because when the load is too large, the belt can slip, and also can start slipping, reducing the starting shock.

- Q: How about white rubber strap yellowing?

- The white rubber band is yellow and rubbed with the weld polish. Remember, the ratio is 1 to 70.

- Q: The difference between roller printing machine and rotary screen printing machine

- Roller printing is a kind of printing process with copper rollers with concave patterns. It is also called copper roll printing. The drum is referred to as cylinder engraving. When printing, the cylinder surface coated with paste, with sharp and flat blade will not cut part of the cylinder surface paste scraping, the concave pattern is reserved in the paste. When the cylinder imprint on the fabric, color transfer to the fabric and printing patterns. Each cylinder of a printing paste, such as printing equipment and equipped with multi cylinder, which can continuously print color patterns. Roller printing in parts of the country also known as iron printing, the principle of consistent with our daily stamp;

- Q: How many layers of rubber band are glued together?

- Three conveyor belts(heat resistant, acid resistant, alkali resistant) products comply with HG2297-92 standard.Flame retardant conveyor beltProduct execution MT147-95 standards.Conveyor belt: it is the main component for dragging and carrying material. When choosing, it adopts cotton canvas, polyester canvas or nylon canvas according to the tension. The other parts of the conveyor design meet all kinds of strong requirements, conveyor belt connection in accordance with different working conditions, mechanical joints, cold glue joints, vulcanizing joints, flexible selection.

- Q: How to distinguish sanlux rubber belt quality

- 1 the cause of the deviation of the conveyer belt is the basic reason of the deviation of the conveyer belt, which is caused by the unbalance of the transverse force during the running of the belt. The main reasons are as follows: 11 installation quality 1) rack and roller are not adjusted straight.2) the roller axis is not perpendicular to the center line of the conveyor belt.3) the frame and the ground connection strength is not enough, the frame is unstable.4) the material and the baffle of the guide trough and the discharging trough are improperly installed and the force is uneven.12 conveyor belt quality 1) conveyor belt joint and central line is not straight.2) conveyor belt with a S shape.13 load quality, loading point is not in the center of conveyor belt.14, maintenance quality, drum cleaning is not clean, sticky coal, material, drum tilt, deformation and so on.2 conveyor belt deviation treatment, conveyor belt deviation many factors, at the same time, because of the belt conveyor type is different, its correction method is not the same. The deviation phenomenon should be analyzed carefully and corresponding measures should be taken.

- Q: What should I pay attention to when the belt conveyor is setting the brake?

- The transportation is the core mechanical braking torque during the braking process, not only with the main parameters of belt conveyer system, and dynamic load time of braking system, brake temperature rise, the factors related to braking nylon and rubber belt does not slip conditions, the braking torque in the braking process is a process, generally speaking. In the process of braking, the braking torque is not fixed;

- Q: JSP what does water swelling rubber belt mean?

- Water swellable rubber sealing strip is imported with special rubber as the main raw material, with a rubber strip products of inorganic absorbent, high viscosity resin and so on more than ten kinds of special material by mixing, mixing, extrusion and the.

- Q: What is the function of the coal feeder? What are the common types of coal feeder?

- Replaceable vibrating feeder, reciprocating feeder and old belt feeder, but the original installation foundation can not be changed at all;The speed control mode can use manual stepless speed change and frequency conversion speed regulation, and can realize field and remote centralized control, which is convenient for remote monitoring and speed regulation.Commonly used coal feeder has a belt feeder, reciprocating feeder, etc.!

- Q: What's the difference between a rubber belt and a polyurethane belt?

- The rubber belt and good flexibility. Good water resistance and water resistance..PU reciprocating work is poor. The high and low temperature performance is poor. Good wear. At room temperature under static conditions. Conversely PU rubber.

Send your message to us

EP belting-Plied textile conveyor belts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches