Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Product Advantages:

OKorder's Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

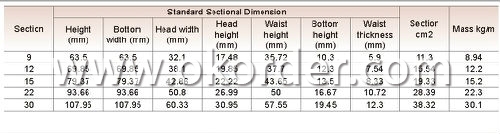

Specifications of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Packaging & Delivery of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: What is the normal tolerance of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20inches the Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: How are steel rails protected from soil settlement?

- Steel rails are protected from soil settlement through a combination of design features and maintenance practices. Firstly, during the construction phase, proper techniques are employed to ensure that the rails are installed on a stable and well-compacted foundation. This helps to minimize the potential for soil settlement. Additionally, various measures are taken to mitigate the effects of soil settlement over time. These include regular inspections and maintenance of the rail infrastructure to identify and address any signs of settlement. For instance, if settlement is detected, the affected area can be raised and stabilized using techniques such as adding additional ballast or compacting the soil. Furthermore, to prevent soil settlement, the area surrounding the rails is often treated with geotextiles or other materials that can help distribute the load and reduce the impact of settlement. These materials provide a barrier between the soil and the rail, minimizing the potential for settlement-induced damage. Overall, a combination of proper construction techniques, routine maintenance, and the use of protective materials helps to protect steel rails from soil settlement. By implementing these measures, railway operators can ensure the long-term stability and safety of the rail infrastructure.

- Q: Do steel rails need to be replaced more frequently in high-traffic areas?

- In high-traffic areas, steel rails require more frequent replacement. The reason for this lies in the higher number of train movements, which causes increased wear and tear on the rails. The continuous weight and pressure exerted by the trains accelerate the wearing down process, necessitating more frequent replacements. Furthermore, heavy loads, like freight trains, are more common in high-traffic areas, further contributing to the deterioration of the rails. Hence, regular inspections and maintenance are vital in these areas to ensure the safety and efficiency of the railway system.

- Q: How are steel rails aligned and leveled?

- Steel rails are aligned and leveled using a combination of techniques such as laser technology, hydraulic jacks, and specialized tools. Laser alignment systems are used to ensure that the rails are straight and parallel to each other. Hydraulic jacks are employed to adjust the height and level of the rails, ensuring a smooth and even surface. Additionally, precision measuring tools are used to check the alignment and levelness of the rails throughout the process.

- Q: What is the role of steel rails in reducing train energy consumption?

- The role of steel rails in reducing train energy consumption is to provide a smooth and durable surface for trains to travel on. The low friction and high strength of steel rails allow trains to move more efficiently, requiring less energy to overcome resistance and maintain their speed. Additionally, steel rails help distribute the weight of the train evenly, reducing the amount of energy needed to propel the train forward.

- Q: What are the different types of rail fastenings used in high-speed steel rail installation?

- There are several types of rail fastenings used in high-speed steel rail installation, including elastic rail clips, pandrol clips, spring clips, and bolted rail joints. These fastenings are designed to securely hold the rails in place while allowing for expansion and contraction due to temperature changes, ensuring safe and efficient operation of high-speed trains.

- Q: What are the noise levels generated by steel rails?

- The noise levels generated by steel rails can vary depending on various factors such as train speed, track conditions, and the type of train being used. However, steel rails typically produce a moderate to high level of noise due to the friction between the train wheels and the tracks. Noise levels can range from around 70 to 100 decibels, which can be significant, especially in urban areas. Efforts are being made to develop quieter rail systems and implement noise reduction measures to mitigate the impact of steel rail noise on surrounding communities.

- Q: Are steel rails affected by changes in ground moisture content?

- Yes, steel rails can be affected by changes in ground moisture content. When the ground moisture content fluctuates, it can lead to changes in the stability and strength of the ground beneath the rails. This can result in movement or shifting of the rails, known as track buckling or track deformations, which can pose safety risks and impact the smooth operation of trains. Therefore, monitoring and managing ground moisture levels is important to ensure the integrity and stability of steel rails.

- Q: Are steel rails prone to rail corrosion?

- Steel rails are indeed prone to rail corrosion. This is because steel is a metal that is susceptible to oxidation when exposed to moisture and other elements. Corrosion occurs when the steel reacts with oxygen in the presence of water or humidity, leading to the formation of iron oxide or rust. Rail corrosion can weaken the integrity of the steel rails over time, leading to structural issues and safety concerns. To combat rail corrosion, various measures can be taken, such as regular inspections, maintenance, and the application of protective coatings. Additionally, using corrosion-resistant alloys or alternative materials like composite rails can also help mitigate the problem of rail corrosion.

- Q: How do steel rails handle train braking forces?

- Steel rails are designed to withstand the immense braking forces generated by trains. The rails have high tensile strength and are securely fastened to the sleepers, which allows them to effectively handle the braking forces. Additionally, the rails are designed to distribute the load evenly across the track, minimizing any potential damage or deformation caused by the braking forces.

- Q: What is the role of steel rails in ensuring train stability?

- Steel rails play a crucial role in ensuring train stability as they provide a solid foundation for the train to travel on. The weight of the train is distributed evenly across the steel rails, which helps to maintain balance and prevent the train from derailing. One of the main functions of steel rails is to guide the train and keep it on track. The rails are designed to have a specific shape, with a flange on the inside of the railhead, which fits into the groove of the train's wheels. This flanged wheel-rail interaction helps to keep the train aligned and prevents it from deviating off the track. Furthermore, steel rails provide a smooth and continuous surface for the train to move on. This reduces the friction between the train's wheels and the rails, allowing the train to travel at high speeds with minimal resistance. This smooth surface also helps to minimize vibrations and bumps, providing a comfortable ride for passengers. In addition to stability, steel rails also contribute to the overall safety of train operations. They are designed to withstand heavy loads and provide resistance against wear and tear. Regular maintenance and inspection of the rails ensure that any defects or damages are promptly identified and repaired, preventing accidents and ensuring the safe passage of trains. Overall, steel rails are essential for train stability as they guide the train, distribute its weight, reduce friction, and provide a safe and smooth surface for the train to travel on. Without steel rails, trains would struggle to maintain stability and safety, making them an indispensable component of railway infrastructure.

Send your message to us

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords