Steel rail high quality for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

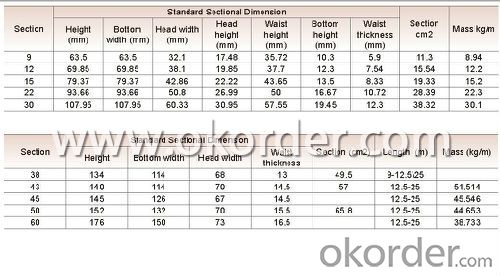

Specifications of High Quality Steel Rail

Product Name: High Quality Steel Rail

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

Applications of High Quality Steel Rail

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of High Quality Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Invoicing on theoretical weight or actual weight as customer request

8. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of High Quality Steel Rail

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q: How are steel rails aligned during installation?

- Steel rails are aligned during installation using precision measurement tools and techniques such as laser alignment systems, track gauges, and string lines. These tools help to ensure that the rails are correctly positioned and aligned with the required specifications, including the proper alignment, levelness, and gauge (distance between the rails). This precise alignment is crucial for the safe and efficient functioning of railway tracks.

- Q: Can steel rails be used in railway systems with heavy snowfall?

- Indeed, steel rails are suitable for railway systems that experience heavy snowfall. They are extensively employed across the globe due to their robustness, resilience, and ability to withstand harsh weather conditions. In areas with substantial snowfall, railway operators implement essential strategies to ensure the seamless operation of train services. These measures encompass regular removal of snow from the tracks and the utilization of specialized equipment such as snowplows or snow blowers. Furthermore, certain railways may employ heating systems or de-icing agents to prevent ice accumulation on the rails. By implementing proper maintenance and winterization techniques, steel rails can effectively endure heavy snowfall while consistently providing dependable transportation services.

- Q: Are steel rails used in underground railways?

- Underground railways commonly utilize steel rails, which serve as a reliable and sturdy base for train locomotion, guaranteeing both stability and safety. The exceptional strength of steel enables it to withstand the substantial loads and continuous utilization inherent in underground railways. Furthermore, steel rails possess a low coefficient of friction, lessening the wear and tear on the tracks and facilitating more seamless and efficient train operations. Consequently, due to their robustness, durability, and exceptional performance attributes, steel rails are unequivocally favored for underground railways.

- Q: Can steel rails be used in industrial or port railway networks?

- Yes, steel rails can be used in industrial or port railway networks. Steel rails are commonly used in railway infrastructure due to their durability, strength, and ability to withstand heavy loads. They provide stability and support for trains, making them ideal for industrial and port railway networks where heavy equipment and cargo are transported.

- Q: Can steel rails be used in extreme temperature conditions?

- Yes, steel rails can be used in extreme temperature conditions. Steel is known for its high strength and durability, allowing it to withstand extreme temperatures without significant deformation or degradation. However, it is important to note that extremely high temperatures, such as those found in wildfires, can affect the structural integrity of steel rails. Regular maintenance and inspection are necessary to ensure their continued safe use in such conditions.

- Q: How are steel rails tested for strength and durability?

- Steel rails are tested for strength and durability through a rigorous process known as rail testing. This testing is conducted to ensure that the steel rails used in railway tracks meet the necessary standards and can withstand the heavy loads and daily wear and tear they are subjected to. One of the primary methods used to test steel rails is the ultrasonic testing method. This involves using high-frequency sound waves to inspect the internal structure of the rail. Ultrasonic waves are sent through the rail, and any disruptions or irregularities in the wave pattern indicate potential defects or weaknesses within the rail. This non-destructive testing method allows for a thorough examination of the steel rails without causing any damage. Another commonly employed testing technique is the hardness testing method. This involves measuring the hardness or resistance of the steel rail's surface to indentation. A specialized instrument known as a hardness tester is used to apply a controlled force on the rail's surface, and the depth of the indentation is measured. This measurement helps determine the rail's strength and resistance to deformation. Additionally, steel rails are subjected to visual inspections. This involves visually examining the rails for any signs of cracks, fractures, or other visible defects. Inspectors often use specialized equipment such as magnifying glasses, cameras, and even drones to ensure a thorough assessment of the rail's condition. To assess the durability of steel rails, accelerated fatigue tests are often conducted. These tests simulate the repetitive loading and unloading that the rails experience under normal operating conditions. The rails are subjected to cyclic loads, and the number of cycles required to cause failure or deformation is recorded. This information helps determine the rail's durability and expected lifespan. Furthermore, steel rails are tested for their resistance to corrosion, which can significantly impact their durability. Corrosion tests involve exposing the rails to various corrosive agents, such as saltwater or acidic solutions, and monitoring their reaction over time. These tests help evaluate the rail's ability to resist corrosion and maintain their structural integrity over prolonged periods. In conclusion, steel rails undergo a comprehensive testing process to ensure their strength and durability. Through techniques such as ultrasonic testing, hardness testing, visual inspections, fatigue tests, and corrosion tests, rail manufacturers and authorities can ensure that the steel rails used in railway tracks meet the necessary quality standards and can withstand the demanding conditions they are exposed to.

- Q: How do steel rails contribute to reducing track maintenance intervals?

- Steel rails contribute to reducing track maintenance intervals in several ways. Firstly, steel rails have high durability and strength, which allows them to withstand heavy loads and frequent train traffic without significant wear and tear. This reduces the need for frequent repairs or replacements of the tracks, thus extending the maintenance intervals. Additionally, steel rails have excellent resistance to corrosion, preventing rust and deterioration that could weaken the tracks and require more frequent maintenance. Furthermore, the smooth surface of steel rails reduces friction between the train wheels and the tracks, minimizing wear and tear on both components. This reduction in friction also improves the overall efficiency of train operations, reducing the need for frequent maintenance intervals. Overall, the use of steel rails provides a reliable and long-lasting infrastructure that minimizes maintenance requirements and enhances the overall efficiency and safety of railway systems.

- Q: How does the weight of a steel rail affect its performance?

- The weight of a steel rail directly affects its performance as it determines its strength, stability, and ability to withstand heavy loads and traffic. Heavier rails provide better support and stability to trains, reducing the risk of derailment and increasing safety. Additionally, heavier rails can handle higher loads and distribute the weight more evenly, resulting in smoother and more efficient train operations.

- Q: What is the impact of heavy axle loads on steel rail performance?

- Heavy axle loads can have a significant impact on steel rail performance. The increased weight puts more stress on the rails, leading to accelerated wear and fatigue. This can result in increased maintenance costs and reduced service life of the rail infrastructure. It may also lead to higher instances of rail defects and derailments, posing safety risks for trains and passengers. Therefore, managing and monitoring axle loads is crucial to maintain the integrity and longevity of steel rails.

- Q: How are steel rails protected against track settlement?

- Steel rails are protected against track settlement through the use of proper ballast and subgrade materials, as well as regular maintenance and inspection. The ballast, which is the layer of crushed stone or gravel beneath the rails, helps distribute the load and stabilize the tracks. Additionally, the subgrade, which is the natural ground below the ballast, needs to be compacted and drained properly to prevent settlement. Regular maintenance and inspections ensure that any issues, such as loose ballast or soft spots, are identified and addressed promptly to maintain the stability of the track.

Send your message to us

Steel rail high quality for sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords