High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering gh Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KGis suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.Tunnel way, curve way, railway, subway, transportation track, express, etc

Product Advantages:

OKorder's High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

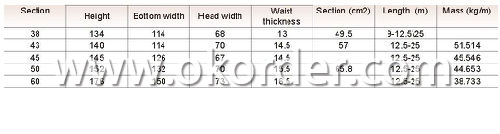

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Package & Delivery of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

Production flow of Steel Heavy Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Can fit in the containers of 20fts the High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG of 6M?

A1: No proble, we can put them into the containers in the form sideling.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

- Q: Are steel rails used in ski resort tramways?

- No, steel rails are not typically used in ski resort tramways. Ski resort tramways, also known as chairlifts or gondolas, are usually supported by towers and cables rather than rails. The chairs or gondolas are attached to the cable and travel along the cable route, carrying skiers and snowboarders up and down the mountain. Steel rails are more commonly used in traditional railways and metro systems, where the train or tram runs on top of the rails.

- Q: What is the impact of heavy freight traffic on steel rails?

- Heavy freight traffic can have a significant impact on steel rails. The constant weight and force exerted by heavy freight trains can lead to wear and tear on the rails, causing them to degrade over time. This can result in increased maintenance needs, including regular inspections, repairs, and potentially even rail replacements. Moreover, the repetitive stress on the rails from heavy freight traffic can also lead to issues such as rail deformation and track misalignment, which can further impact the overall safety and efficiency of the rail infrastructure.

- Q: How do steel rails contribute to the overall smoothness of train travel?

- Steel rails contribute to the overall smoothness of train travel through several key factors. Firstly, steel rails provide a stable and durable surface for trains to run on. The smoothness of the steel rails ensures that the wheels of the train make consistent and uninterrupted contact with the track, resulting in a smoother ride. Additionally, steel rails have a high level of strength and resistance to deformation. This means that they can withstand the heavy weight of the train and distribute the load evenly, preventing any unevenness or bumps along the track. This even distribution of weight helps to reduce vibrations and shocks, resulting in a smoother and more comfortable journey for passengers. Moreover, steel rails are designed to be precisely aligned and maintain their shape over long distances. This alignment ensures that the train wheels follow a consistent path, reducing any lateral movement or swaying. The absence of lateral movement contributes to a smoother ride and helps to minimize the jostling and side-to-side motion experienced by passengers. Furthermore, steel rails are regularly maintained and inspected to ensure their smoothness. Any defects or irregularities, such as cracks or wear, are promptly identified and repaired. This maintenance work helps to maintain the smoothness of the rails and prevent any potential disruptions or discomfort during train travel. In conclusion, steel rails play a crucial role in providing a smooth and comfortable train travel experience. Their stability, strength, alignment, and regular maintenance all contribute to minimizing vibrations, shocks, and lateral movement, resulting in a smoother ride for passengers.

- Q: What are the different methods of measuring rail profile and wear using steel rails?

- There are several methods for measuring rail profile and wear using steel rails. One common method is the use of rail profile measurement devices, such as laser-based systems or contact-based devices. These devices can accurately measure the dimensions of the rail, including the height, width, and flange angle, allowing for a comprehensive assessment of the rail profile. Another method is the use of ultrasonic testing, which involves sending high-frequency sound waves through the rail to detect any defects, cracks, or wear. This non-destructive testing method provides valuable information about the condition of the rail and allows for early detection of potential issues. Furthermore, visual inspections are often conducted to visually assess the wear patterns on the rail surface. This method involves visually inspecting the rail for signs of excessive wear, such as head loss, gauge corner cracking, or surface spalling. These visual inspections can be complemented by using handheld measuring tools, such as calipers or wear gauges, to measure specific wear parameters, including the depth of wear. Overall, a combination of these methods is typically employed to accurately measure rail profile and wear, ensuring the ongoing safety and efficiency of rail infrastructure.

- Q: What are the different methods used for rail welding on steel rails?

- There are several methods used for rail welding on steel rails, including flash butt welding, thermite welding, and electric arc welding. Each method has its own advantages and disadvantages, but they all aim to create a strong and continuous weld that can withstand the stresses and strains of railway operations. Flash butt welding involves using an electric current to heat the ends of two rail segments, which are then pressed together to form a weld. Thermite welding utilizes a chemical reaction to generate intense heat, which is used to melt a thermite mixture that fills the gap between the rail ends. Electric arc welding involves the use of an electric arc to heat the rail ends, and then a filler material is added to create the weld. The choice of welding method depends on factors such as the rail type, environmental conditions, and the specific requirements of the rail network.

- Q: How are steel rails protected against excessive heat and cold?

- Steel rails are protected against excessive heat and cold through various methods such as thermal expansion joints, insulation materials, and temperature monitoring systems. These measures help prevent rail buckling or contraction due to extreme temperatures, ensuring the safety and durability of the railway infrastructure.

- Q: Can steel rails be used in areas with high wind speeds?

- Yes, steel rails can be used in areas with high wind speeds. Steel is a durable and strong material that can withstand the forces exerted by high winds. Additionally, rails are typically anchored securely to the ground, providing further stability. However, it is important to consider and design for the potential effects of high winds on rail infrastructure to ensure safe and reliable operation.

- Q: How are steel rails protected from theft?

- Steel rails are protected from theft through a combination of various security measures. One of the primary methods used is the installation of security fences and barriers around rail yards and tracks to restrict unauthorized access. These fences are often equipped with surveillance cameras and alarm systems to deter potential thieves and alert authorities in case of any suspicious activity. In addition to physical barriers, rail companies also employ other advanced technologies to safeguard their steel rails. Many rail lines are equipped with trackside detection systems that can detect any unauthorized movement or tampering with the rails. These systems use sensors and monitoring devices to continuously monitor the integrity of the tracks and immediately transmit alerts if any abnormalities are detected. Furthermore, some rails are marked with unique identification numbers or engraved with specific codes that are easily traceable. This makes it difficult for thieves to sell stolen rails as they can be easily identified and tracked back to the original owner. Rail companies also actively collaborate with law enforcement agencies and scrap metal dealers to ensure stolen rails are quickly identified and recovered. Overall, the protection of steel rails from theft is a multi-layered approach that combines physical barriers, advanced technologies, and collaboration with authorities. These measures aim to deter potential thieves, detect any unauthorized activity, and facilitate the recovery of stolen rails, ultimately ensuring the integrity and safety of rail infrastructure.

- Q: What are the factors to consider when selecting steel rails for a specific application?

- When selecting steel rails for a specific application, several factors need to be considered. These factors include the load requirements, operating conditions, track geometry, rail profile, and material properties. The load requirements determine the rail's strength and stiffness, ensuring it can withstand the applied loads. The operating conditions, including temperature, corrosion, and abrasion, impact the rail's durability and longevity. Track geometry influences the rail's dimensions and shape to ensure proper alignment and stability. Rail profile determines the interaction between the wheel and rail, affecting ride quality and safety. Lastly, material properties such as hardness, toughness, and fatigue resistance are crucial for selecting rails that can withstand repeated stresses and maintain their structural integrity.

- Q: What is the typical lifespan of steel rails?

- The typical lifespan of steel rails can vary depending on various factors such as usage, maintenance, and environmental conditions. However, with proper maintenance and regular inspections, steel rails can last anywhere from 30 to 50 years or even longer.

Send your message to us

High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords