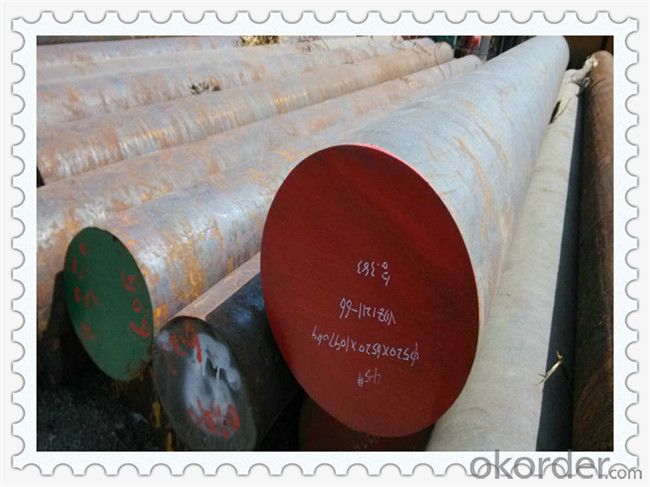

H13 Forged Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

H13 Forged Steel Round Bar

Material: |

h13 forged steel round bar

|

Comparative standards: JIS SKD61,AISI/ASTM H13,Nr.W 1.2344.DIN X40CrMoV5, GB 4Cr5MoSiV1

| |

hot work tool steel h13 Chemical Composition as following or customized CSiMnCrSPMoV0.400.950.355.00.030.031.100.85 | |

Diameter: |

hot work tool steel h13 round bars size range : GradeH13 Hot rolled size range: Dia 16mm-45mm Forged size range: Dia50mm-650mm Max dia800mm EFS size range:Dia16mm-480mm Min dia16mm ESR size range:Dia16mm-800mm

hot work tool steel h13 flat bars size range: GradeH13 Hot rolled size range:thickness 15mm-45mm Width :Max 610mm Min thickness15mmForged size range:thickness 50mm-450mmMax thickness500mmWidth :Max 1400mm EFS size range:thickness 15mm-280mm Min width105Width: max 800mmMax width2000mmESR size range:thickness 15mm-450mm Width: max 2000mm

hot work tool steel bar h13 square bars size range : GradeH13 Hot rolled size range:max45mm Forged size range:50mm-650mm Max square650mm EFS size range: max square 500mm ESR size range: max square 650mm

|

Length: |

2000mm-5800mm of fix length as customized , Straightness: 3mm/M max;

|

Process: |

EAF + LF + VD +(ESR) + Forged +annealed condition (optional)

|

Delivery condition: |

Hot forged +Rough machined + Turned (as for round bars) / milled in four faces (as for steel plates or flat bars)

|

Delivery Time: |

20 days

|

MOQ: |

3 tons

|

Heat treatment: | Normalized / Annealed / Quenched / tempered |

Forged ratio: |

no less than 4:1

|

Technical Data: |

According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing

|

Test: |

Ultrasonic test according to SEP 1921-84 G3 C/c

|

Certificate of Quality |

in addition the normal terms, production process, the mechanical property forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the Certificate of Quality

|

Marking: |

Grade, heat NO. length will be stamped one each bar with required color

|

Payment: |

30% advance by T\T; Balance pay before the shipment against shipping documents or irrevocable LC at sight

|

Application of tool steel H13: |

hot extrusion dies, forging die forging hammer, forging press die, precision forging die well as aluminum, copper and alloys die-casting mold.

|

- Q: Can steel round bars be used in the production of construction materials?

- Yes, steel round bars can be used in the production of construction materials. Steel round bars are commonly used in the construction industry due to their high strength and durability. They can be used to reinforce concrete structures, such as beams, columns, and slabs, providing additional strength and stability. Steel round bars can also be used in the fabrication of steel frames, trusses, and other structural components in buildings and bridges. Their versatility and ability to withstand heavy loads make them a popular choice in the construction industry.

- Q: Can steel round bars be used in the automotive manufacturing?

- Yes, steel round bars can be used in automotive manufacturing. Steel round bars are commonly used in the production of various automotive components such as axles, crankshafts, connecting rods, and suspension parts. They offer excellent strength, durability, and impact resistance, making them suitable for withstanding the rigorous demands of automotive applications. Additionally, steel round bars can be easily machined and fabricated to meet specific design requirements, ensuring precise and reliable performance in the automotive industry.

- Q: What are the different types of steel round bars used in the automotive aftermarket?

- There are several different types of steel round bars used in the automotive aftermarket, including carbon steel, alloy steel, and stainless steel. These bars are commonly used for various applications such as suspension systems, drivetrain components, and chassis reinforcement. The specific type of steel round bar used depends on the desired strength, durability, and corrosion resistance for the particular automotive part.

- Q: Can steel round bars be used in the manufacturing of fasteners?

- Yes, steel round bars can be used in the manufacturing of fasteners. Steel round bars are often used as raw materials to create fasteners such as screws, bolts, and nuts. The round shape of the bars allows for easy shaping and machining to meet the desired specifications of the fasteners. Additionally, steel is a strong and durable material that provides the necessary strength and resilience required for fasteners to withstand various applications and loads. Therefore, steel round bars are commonly utilized in the manufacturing of fasteners due to their mechanical properties and versatility.

- Q: What are the factors to consider when selecting a steel round bar?

- When selecting a steel round bar, there are several factors that should be taken into consideration. Firstly, it is important to consider the grade of steel. Different grades of steel have varying properties and strengths, so the specific application and requirements should be evaluated. For example, if high corrosion resistance is needed, stainless steel grades like 304 or 316 may be suitable, whereas for structural applications, carbon steel grades like A36 or 1018 may be more appropriate. Secondly, the dimensions and size of the round bar should be considered. This includes the diameter, length, and tolerance requirements. The size should be chosen based on the specific application, load-bearing capacity, and the available space for installation. Thirdly, the surface finish and condition of the round bar should be assessed. This includes factors such as surface roughness, straightness, and any surface defects. The surface finish should be selected based on the desired aesthetics, functional requirements, and the manufacturing process. Another important factor is the availability and cost of the steel round bar. It is crucial to consider the availability of the desired grade and size from suppliers, as well as the associated cost. It is advisable to compare prices from different suppliers to ensure the best value for money. Furthermore, the required mechanical properties of the steel round bar should be evaluated. This includes factors such as tensile strength, yield strength, hardness, and ductility. The mechanical properties should align with the intended application and load-bearing requirements. Lastly, it is essential to consider any additional requirements or certifications that may be needed. This could include compliance with specific industry standards (e.g., ASTM, ISO), certifications (e.g., RoHS, REACH), or specific testing requirements (e.g., ultrasonic testing, impact testing). In conclusion, when selecting a steel round bar, it is important to consider the grade, dimensions, surface finish, availability, cost, mechanical properties, and any additional requirements. Taking into account these factors will help ensure that the steel round bar chosen is suitable for the intended application and meets all necessary specifications.

- Q: How are steel round bars tested for tensile strength?

- Steel round bars are tested for tensile strength using a method called a tensile test. This test measures the resistance of a material to a stretching force, and it is commonly used to determine the mechanical properties of metals. To perform a tensile test on a steel round bar, a sample is taken from the bar in the form of a cylinder or a rectangular shape. The sample is then prepared by removing any surface imperfections or irregularities. Next, the sample is inserted into a testing machine called a tensile testing machine. The machine consists of two grips, one at each end, which securely hold the sample. One grip is fixed while the other is movable. The testing machine applies an increasing force to the sample, causing it to stretch until it eventually breaks. As the force is applied, the machine measures the amount of force required to stretch the sample and records the elongation or deformation of the sample throughout the test. The test results are used to calculate various mechanical properties of the steel round bar, including its ultimate tensile strength. This is the maximum amount of stress the material can withstand before it breaks. Other properties such as yield strength, elastic modulus, and elongation at break can also be determined from the test. Tensile testing is a critical method for determining the quality and suitability of steel round bars for various applications. It helps ensure that the material meets the required specifications and can withstand the expected loads and stresses in its intended use.

- Q: Can steel round bars be used in the automotive parts industry?

- Indeed, the automotive parts industry does make use of steel round bars. These bars, renowned for their remarkable strength, resilience, and ability to withstand wear and tear, are frequently employed in the production of diverse automotive components. By shaping and sizing these bars to suit the specific needs of axles, drive shafts, suspension components, steering components, and gears, manufacturers ensure that automotive parts are crafted to the highest standards. The utilization of steel round bars guarantees the structural soundness and dependability of these components, rendering them perfectly equipped to endure the rigorous conditions and burdens encountered in the automotive sector.

- Q: Can steel round bars be used in the construction equipment industry?

- Yes, steel round bars are commonly used in the construction equipment industry. Steel round bars are known for their strength, durability, and versatility, making them suitable for various applications in construction equipment. They can be used to manufacture components such as axles, shafts, pins, and fasteners. The high strength of steel round bars ensures that the construction equipment can withstand heavy loads and harsh working conditions. Additionally, steel round bars can be easily machined and welded, allowing manufacturers to create complex and customized designs for construction equipment. Overall, steel round bars are widely utilized in the construction equipment industry due to their exceptional mechanical properties and ability to enhance the performance and longevity of the equipment.

- Q: Can steel round bars be used for making suspension springs?

- Yes, steel round bars can be used for making suspension springs. Steel is a commonly used material for suspension springs due to its high strength and durability. The round bars can be forged or shaped into the desired spring shape and then heat-treated to achieve the desired spring characteristics. Additionally, steel round bars can be easily machined and drilled to accommodate different suspension systems and components. However, it is important to consider the specific requirements and load capacity of the suspension system to ensure that the chosen steel round bars are suitable for the intended application.

- Q: What are the advantages of using nickel-iron alloy steel round bars?

- Nickel-iron alloy steel round bars offer several advantages. Firstly, they exhibit excellent corrosion resistance, making them suitable for applications in harsh environments. Additionally, these bars possess high mechanical strength and toughness, allowing them to withstand heavy loads and impacts. They also have good thermal stability, making them ideal for use in high-temperature applications. Moreover, nickel-iron alloy steel round bars have good magnetic properties, making them suitable for use in electromagnetic applications. Overall, the combination of corrosion resistance, mechanical strength, thermal stability, and magnetic properties make nickel-iron alloy steel round bars advantageous in various industrial applications.

Send your message to us

H13 Forged Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords