Tool Steel Cold Rolled 1.2379 Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

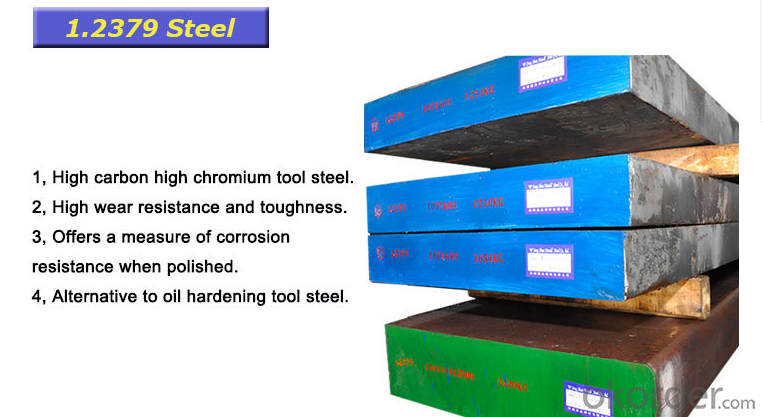

Tool Steel Cold Rolled 1.2379 Steel Bar r

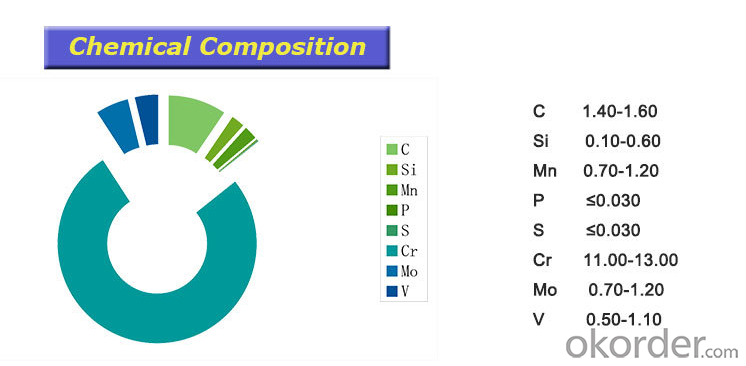

Product information:

Specifications

Hot Selling Tool Steel Cold Rolled 1.2379 Steel Bar Prices

1.A/N/Q+T

2.Sample free

3.Black or Bright

4.T Max:800mm

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q:How does special steel contribute to the construction machinery industry?

- Special steel plays a crucial role in the construction machinery industry by providing high-strength and durable components. These components are essential for heavy-duty applications in construction machinery, such as excavators, bulldozers, cranes, and loaders. One of the key contributions of special steel to the construction machinery industry is its ability to withstand extreme stress and load-bearing requirements. Construction machinery often operates under severe conditions, including heavy loads, vibrations, and impacts. Special steel, with its excellent mechanical properties, can resist these conditions and maintain its structural integrity, ensuring the safety and reliability of the equipment. Moreover, special steel is often used in critical components of construction machinery, such as booms, buckets, tracks, and gears. These components are subjected to intense wear and tear due to constant use in harsh environments. Special steel, engineered with enhanced hardness and wear resistance, helps extend the lifespan of these components, reducing maintenance costs and downtime. Additionally, special steel provides superior corrosion resistance, which is vital for construction machinery used in humid or corrosive environments. By preventing rust and decay, special steel helps maintain the equipment's performance and longevity, ultimately increasing productivity and efficiency in construction projects. Furthermore, special steel enables the construction machinery industry to achieve innovative designs and advanced functionalities. Its versatility allows for the creation of complex shapes and precise tolerances, which are essential for optimizing the performance and efficiency of machinery. Special steel also enables the incorporation of advanced technologies, such as sensors and automation, enhancing the accuracy and productivity of construction equipment. In summary, special steel contributes significantly to the construction machinery industry through its ability to withstand extreme conditions, provide superior wear resistance and corrosion protection, and enable innovative designs. By utilizing special steel in the manufacturing process, construction machinery manufacturers can ensure the durability, safety, and efficiency of their equipment, ultimately benefiting the construction industry as a whole.

- Q:How does special steel perform in high-temperature oxidation with sulfur-containing atmospheres?

- Special steel performs well in high-temperature oxidation with sulfur-containing atmospheres due to its enhanced resistance to sulfur-induced corrosion. The alloy composition and surface treatment of special steel enable it to form a protective oxide layer that prevents sulfur from penetrating the material, thereby reducing the risk of oxidation and corrosion.

- Q:How is special steel different from regular steel?

- Special steel is different from regular steel due to its unique composition and manufacturing process. It contains additional alloying elements such as chromium, nickel, or molybdenum, which enhance its strength, hardness, corrosion resistance, and other specific properties. Special steel is carefully engineered to meet specific industrial requirements, making it suitable for applications that demand exceptional performance, durability, and resistance to wear and tear.

- Q:How does special steel contribute to the manufacturing of cutting tools?

- Special steel is a key component in the manufacturing of cutting tools due to its exceptional properties such as high hardness, toughness, and wear resistance. These characteristics enable cutting tools to withstand the rigors of various cutting operations, ensuring longer tool life and improved cutting performance. Furthermore, special steel can be customized to meet specific requirements, making it an ideal choice for manufacturing cutting tools that are used in a wide range of industries, including automotive, aerospace, and manufacturing.

- Q:Can special steel be used in the sporting goods manufacturing industry?

- Yes, special steel can be used in the sporting goods manufacturing industry. Special steel, with its unique properties such as high strength, durability, and corrosion resistance, can be utilized in the production of various sporting goods such as golf clubs, baseball bats, tennis rackets, and bicycle frames. The use of special steel in these products enhances their performance, increases their lifespan, and provides better overall quality to athletes and sports enthusiasts.

- Q:How does special steel contribute to the infrastructure sector?

- Special steel plays a crucial role in the infrastructure sector by contributing to the construction and maintenance of various structures. It is widely used in the sector due to its exceptional strength, durability, and resistance to wear and tear. One of the key areas where special steel makes a significant contribution is in the construction of bridges. Bridges are subjected to heavy loads, extreme weather conditions, and constant vibrations, making the use of high-quality steel essential. Special steel, such as high-strength low-alloy (HSLA) steel or weathering steel, provides the necessary strength and corrosion resistance to ensure the longevity and safety of bridges. Moreover, special steel is also extensively utilized in the construction of high-rise buildings and skyscrapers. These structures require steel that can withstand tremendous loads and provide stability. Special steel grades, such as high-strength steel or structural steel, offer the necessary strength-to-weight ratio, allowing architects and engineers to design taller and more robust structures. In addition to its usage in construction, special steel also contributes to the infrastructure sector through its application in manufacturing equipment and machinery used for construction and maintenance activities. It is used in the production of heavy machinery, cranes, excavators, and other construction equipment, providing the necessary strength and reliability to withstand the demanding conditions of the sector. Furthermore, special steel is crucial in the development of transportation infrastructure. It is used in the manufacturing of railway tracks, ensuring their durability and resistance to wear caused by the continuous movement of trains. Additionally, it is used in the production of reinforcing bars for concrete in road construction, providing the necessary strength and stability to withstand heavy traffic loads. Overall, special steel's exceptional properties make it an indispensable material in the infrastructure sector. Its strength, durability, and resistance to corrosion contribute to the construction and maintenance of various structures, ensuring their longevity, safety, and reliability.

- Q:What are the characteristics of high-speed steel?

- High-speed steel (HSS) is known for its exceptional durability and heat resistance. It has excellent hardness, toughness, and wear resistance, making it suitable for cutting tools and machining applications. HSS can withstand high temperatures without losing its hardness, allowing it to cut at high speeds without losing its sharpness. Additionally, it has good dimensional stability and can maintain its shape even under extreme conditions.

- Q:How does special steel contribute to the oil and gas industry?

- Special steel plays a crucial role in the oil and gas industry by providing strength, corrosion resistance, and durability to equipment and infrastructure. It is used in the construction of pipelines, drill pipes, wellheads, valves, and various other components. The unique properties of special steel enable it to withstand harsh operating conditions, high pressures, and corrosive environments, ensuring the reliability and safety of oil and gas operations.

- Q:Can special steel be used for automotive engine components?

- Yes, special steel can be used for automotive engine components. Special steel, such as high-strength alloys or stainless steel, can offer superior mechanical properties, corrosion resistance, and heat resistance, making it suitable for demanding engine applications.

- Q:What are the common challenges in heat treating special steel?

- Some common challenges in heat treating special steel include achieving the desired hardness and strength while minimizing distortion and cracking, ensuring uniform heat distribution throughout the steel, managing the transformation of phases during heating and cooling, controlling the formation of detrimental microstructures, and maintaining tight dimensional tolerances. Additionally, special steels may have specific alloying elements or compositions that require precise heat treatment processes to maximize their desired properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tool Steel Cold Rolled 1.2379 Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords