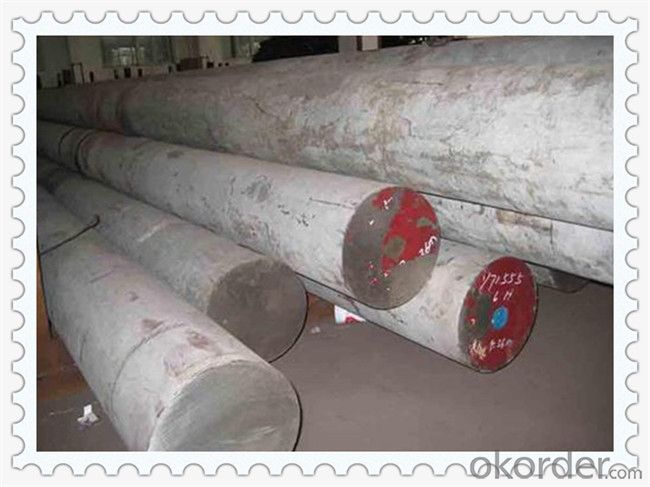

1.2311 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.2311 Steel Round Bar

Grade: 3Cr2Mo/P20/1.2311/Bp20

Characteristic

1, Good hardenability.

2, Polished good performance

3, Good mechanical properties.

4, Section's hardness is uniform.

Chemical composition of 3Cr2Mo

| C | Si | Mn | Cr | Mo | P | S |

| 0.28~0.40 | 0.20~0.80 | 0.60~1.00 | 1.40~2.00 | 0.30~0.55 | ≤0.030 | ≤0.030 |

Specification

Round bar | Diameter (mm) | Length (mm) | |

50~500 | 2000~5800 | ||

plate/sheet | Thickness (mm) | Width (mm) | Length (mm) |

20~400 | 80~1000 | 2000~5800 |

Steel Surface

Steel Sharp | Surface treatment |

Round bar | Black /Grinding / Polished / Peeled / Turned |

steel plate | Black / Milling / Machined |

Application

1. 3Cr2Mo is suitable for making medium and large,sophishticated long-life plastic mold steel.

2. 3Cr2Mo is suitable for manufacturing low melting point alloy die casting and heavy mold main components.

Physical properties

Thermal conductivity

| Temperature/°c | 20 | 100 | 200 | 300 | 400 |

| Thermal conductivityλ/W•(m•K)¯¹ | 36.0 | 33.4 | 31.4 | 30.1 | 29.3 |

Coefficient of expansion

| Temperature/°C | 18~100 | 18~200 | 18~300 | 18~400 | 18~500 | 18~600 | 18~700 |

| Coefficient of expansion/°C-1 | 11.9*10-6 | 12.20*10-6 | 12.5*10-6 | 12.81*10-6 | 13.11*10-6 | 13.41*10-6 | 13.71*10-6 |

Company equipment

smelting equipment : 3 and 4 tons induction furnaces;electric slag furnaces of 0.5t,1t,3t,5t,especially 3 and 5 tons electric slag

furnaces which feature both unipolar and bipolarity series functions.etc.

Processing equipments : electric hydraulic hammer; supporting equipments, gas producer, reheating furnace, gas annealing

furnace, electric annealing saw, etc.

Detective equipments : functions of chemical annalysis, physics property and mechnical property, etc.

- Q: Can steel round bars be used for making molds?

- Steel round bars can be used for making molds, but it may not be the most common or ideal choice of material. Steel round bars are typically used for structural applications or as support components. When it comes to making molds, other materials such as silicone, aluminum, or even specific types of steel molds are typically preferred. These materials offer better heat resistance, flexibility, and ease of use for molding purposes. That being said, if the steel round bars are properly machined, shaped, and treated, they can still be used to create simple molds for certain applications. However, it is important to consider the specific requirements of the mold, including the material being molded, the temperature and pressure conditions, and the desired finish of the final product, before deciding on the use of steel round bars.

- Q: Are steel round bars suitable for the production of axles?

- Yes, steel round bars are suitable for the production of axles. Steel round bars are known for their high strength and durability, making them ideal for the heavy-duty requirements of axles. They can withstand the forces and stresses applied during operation, ensuring the axles can efficiently support and transmit the load. The round shape of the bars also allows for easy machining and forming into axles of various sizes and configurations.

- Q: Are steel round bars suitable for plumbing applications?

- Yes, steel round bars can be suitable for plumbing applications. Steel is a durable and strong material, making it ideal for plumbing systems that require high pressure and load-bearing capabilities. Steel round bars can be used for various plumbing components such as pipes, fittings, valves, and supports. They are commonly used in applications where corrosion resistance and longevity are important, such as in water supply systems, underground piping, and industrial plumbing. However, it is important to consider the specific requirements of the plumbing application, including factors like water quality, temperature, and compatibility with other materials. Additionally, proper installation and maintenance are crucial to ensure the effectiveness and longevity of steel round bars in plumbing systems.

- Q: What are the different marking methods for steel round bars?

- The different marking methods for steel round bars include stamping, engraving, etching, laser marking, and inkjet printing. These methods are used to imprint important information such as the grade, size, heat number, manufacturer's logo, and other specifications on the surface of the round bars.

- Q: What are the safety precautions when handling steel round bars?

- To minimize the chance of accidents or injuries, it is important to adhere to several safety precautions when dealing with steel round bars. 1. Personal Protective Equipment (PPE) should always be worn. Safety goggles, gloves, steel-toed boots, and a hard hat are essential in safeguarding against potential hazards like flying debris, sharp edges, and heavy objects. 2. Proper lifting and carrying techniques are crucial. Due to the weight and bulkiness of steel round bars, it is vital to employ correct lifting methods to prevent strain or injury. Lift with your legs, maintain a straight back, and avoid twisting or jerking movements. If the bars are too heavy, seek assistance or employ mechanical aids like forklifts or cranes. 3. Ensure secure storage and stacking. Properly securing and organizing steel round bars when storing or stacking them is imperative. Use appropriate storage racks or A-frames to prevent tipping or falling, which could result in severe injuries. When stacking multiple bars, employ spacers or shims to maintain stability. 4. Be cautious of sharp edges. Steel round bars might possess sharp edges or burrs, necessitating care when handling. Wearing gloves is advised to protect your hands, and avoid dragging or sliding the bars to prevent cuts or abrasions. 5. Employ proper handling techniques. Maintain a firm grip when moving steel round bars and be aware of your surroundings. Do not swing or throw the bars, as they may strike someone or cause damage. Instead, walk slowly and steadily, ensuring clear pathways and ample space for maneuvering. 6. Inspect for defects. Prior to using steel round bars, examine them for any defects or damage that could compromise their structural integrity. Look for cracks, dents, or deformities. If any issues are detected, refrain from using the bars and report them to a supervisor or quality control personnel. 7. Observe fire safety measures. Steel round bars are highly flammable when exposed to extreme heat or sparks. Hence, avoid working near open flames or hot work areas. Keep fire extinguishers nearby and ensure that everyone is trained in fire safety protocols. By adhering to these safety precautions, the risks associated with handling steel round bars can be significantly minimized, creating a safer work environment.

- Q: Are steel round bars suitable for outdoor applications?

- Indeed, outdoor applications find steel round bars to be highly suitable. The remarkable durability and strength of steel have established it as a preferred option for numerous outdoor structures and applications. Construction, fencing, gates, outdoor furniture, and other outdoor structures frequently rely on steel round bars owing to their ability to withstand corrosion and weathering. Moreover, the resistance of steel round bars against outdoor elements can be further fortified through painting or coating.

- Q: What is the maximum load capacity of a steel round bar?

- Various factors, including the diameter, length, and grade of the steel, influence the maximum load capacity of a steel round bar. Steel round bars are engineered to endure different levels of stress, resulting in varying load capacities. Generally, the yield strength and ultimate tensile strength of the steel determine the load capacity. To ascertain the maximum load capacity of a particular steel round bar, it is imperative to refer to engineering specifications or manufacturer-provided reference materials. These specifications will furnish the necessary data to compute the load capacity based on the precise dimensions and characteristics of the round bar. It is crucial to emphasize that load capacity calculations should be entrusted to qualified professionals who possess a comprehensive comprehension of structural engineering principles and material properties.

- Q: What are the different tolerances for steel round bars?

- The different tolerances for steel round bars depend on various factors such as the diameter, length, and intended application. Common tolerances for steel round bars include diameter tolerances ranging from +/- 0.005 inches to +/- 0.030 inches, length tolerances ranging from +/- 0.125 inches to +/- 0.500 inches, and straightness tolerances ranging from 0.0125 inches per foot to 0.030 inches per foot. However, specific tolerances may vary depending on the specific requirements set by the industry or customer.

- Q: Can steel round bars be used in the chemical industry?

- Yes, steel round bars can be used in the chemical industry. Steel is a versatile material with excellent mechanical properties and corrosion resistance, making it suitable for various applications in the chemical industry. Steel round bars are commonly used for manufacturing equipment, such as reactors, tanks, and piping systems, where strength, durability, and resistance to chemical substances are important factors.

- Q: Are steel round bars available in metric sizes?

- Metric sizes of steel round bars are indeed available. Many manufacturers and suppliers cater to customers who utilize the metric system by offering steel round bars in addition to the standard imperial sizes. These metric measurements are commonly utilized in countries that adhere to the metric system as their primary unit of measurement. They provide a diverse selection of metric diameters and lengths suitable for various applications and industries. To ensure the availability of steel round bars in the desired metric sizes, it is advisable to verify with the specific supplier or manufacturer.

Send your message to us

1.2311 Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords