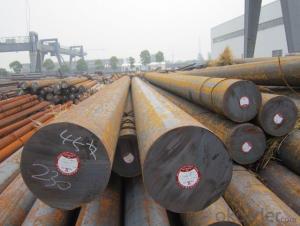

Mould Steel Round Bar 1.2379

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mould Steel Round Bar 1.2379 / SAE 8620 Forging Round Steel Bar

Process: EAF+LF+VD+ Hot Forged+Turned(Optinal)+ Heat treatment (Optinal)

Chemical composition (%)

| Grade | C | Si | Mn | P ≤ | S ≤ | Cr | Mo | V |

| Cr12Mo1V1 | 1.40-1.60 | ≤ 0.60 | ≤ 0.60 | 0.030 | 0.030 | 11.00-13.00 | 0.70-1.20 | 0.5-1.10 |

Production Specification

Material: | forged mould steel round bar

|

Diameter: | 250mm-800mm

|

Length: | 2000mm-12000mm Straightness: 3mm/M max; square bar.150-800mm, blocks sizes up to 800*800mm

|

Process: | EAF + LF + VD +(ESR) + Forged + Heat Treatment (optional)

|

Delivery condition: | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) |

Delivery Time: | 30 days

|

MOQ: | 20 tons

|

Heat treatment: | Normalized / Annealed / Quenched / tempered |

Forged ratio: | no less than 3:1

|

Technical Data: | According to the customer's requirement of Chemical Composition, Physical Properties and Mechanical Testing; mould steel round bar available for test |

Test: | Ultrasonic test according to SEP 1921-84 G3 C/c

|

Certificate of Quality | issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness), forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the Certificate of Quality

|

Marking: | Grade, heat NO. length will be stamped one each bar with required color

|

Payment: | 30% advance by T\T; Balance pay before the shipment against shipping documents or irrevocable LC at sight

|

Application: | Statically and dynamically stressed components for vehicles, engines and machines. For parts of larger cross-sections, crankshafts, gears. |

- Q: What is the Young's modulus of a steel round bar?

- The Young's modulus of a steel round bar is a measure of its stiffness or elasticity. It is a material property that determines how much a material deforms under a given load and is defined as the ratio of stress to strain. For steel, the Young's modulus typically ranges from 190 to 210 gigapascals (GPa). This means that for every unit of stress applied to the steel round bar, the strain experienced by the bar is approximately 190 to 210 times greater. The actual Young's modulus of a specific steel round bar may vary depending on various factors such as the specific grade of steel, its composition, and any heat treatment it has undergone. Therefore, it is important to consult the relevant material specifications or conduct specific testing to determine the exact Young's modulus for a particular steel round bar.

- Q: What is the tensile strength of steel round bars?

- The tensile strength of steel round bars varies depending on the specific grade or type of steel used. On average, steel round bars possess a tensile strength ranging from 400 to 500 megapascals (MPa). This implies that steel round bars can endure a pulling or stretching force of 400 to 500 MPa before undergoing permanent deformation or fracturing. It is worth mentioning that varying grades of steel, such as mild steel, carbon steel, or alloy steel, may exhibit different tensile strength values. Moreover, factors like heat treatment, manufacturing process, and round bar size can also impact its tensile strength. Therefore, it is advisable to seek accurate and precise information regarding the tensile strength of a particular steel round bar from the specific manufacturer or supplier.

- Q: Can steel round bars be used in the manufacturing of bicycles?

- Yes, steel round bars can be used in the manufacturing of bicycles. Steel is a commonly used material in bicycle manufacturing due to its strength, durability, and affordability. Steel round bars can be shaped, welded, and manipulated to form the frame, handlebars, and other components of a bicycle.

- Q: Can steel round bars be used in the production of forgings?

- Yes, steel round bars can be used in the production of forgings. Steel round bars are commonly used as raw materials for forging processes. The round bars are heated to a specific temperature and then shaped using various forging techniques such as hammering, pressing, or rolling. The heat and pressure applied during the forging process help to enhance the mechanical properties of the steel, making it stronger and more durable. Steel round bars are ideal for producing forgings as they provide a consistent and uniform shape, ensuring the final product meets the required specifications. Additionally, steel round bars offer versatility in terms of size, grade, and composition, allowing for a wide range of applications in various industries such as automotive, aerospace, and construction.

- Q: Can steel round bars be used in the production of power tools?

- Certainly! Steel round bars have the capability to be utilized in the manufacturing process of power tools. Steel, being a resilient and robust material, is frequently employed in the production of a wide range of tools and machinery, particularly power tools. The implementation of steel round bars can contribute to the creation of power tool bodies, handles, and other vital components, thereby enhancing stability, strength, and longevity. Power tool manufacturers often opt for steel with high tensile strength and resistance to wear and tear. Furthermore, steel possesses the advantage of being easily machinable, allowing for precise shaping and customization of power tool components. In summary, the utilization of steel round bars is a suitable and advantageous choice for the production of power tools due to their strength, durability, and versatility.

- Q: Can steel round bars be used for making medical equipment?

- Yes, steel round bars can be used for making medical equipment. Steel is a strong and durable material that can be easily shaped into various forms, including round bars. These round bars can be further processed and machined to create different components or structures required in medical equipment such as surgical instruments, implantable devices, and hospital furniture. Additionally, steel is also known for its corrosion resistance, making it suitable for applications in the medical field.

- Q: How are steel round bars used in the manufacturing of lifting equipment?

- Steel round bars are commonly used in the manufacturing of lifting equipment due to their high strength and durability. These bars are often used to construct the main structural components, such as the frames or arms, of lifting equipment like cranes or hoists. The round shape of the bars provides stability and prevents bending or distortion when heavy loads are lifted. Additionally, the steel material ensures the equipment can handle the stress and weight, making it reliable and safe for lifting operations.

- Q: Can steel round bars be used for making marine equipment?

- Yes, steel round bars can be used for making marine equipment. Steel is a durable and corrosion-resistant material that is commonly used in the marine industry for various applications such as shipbuilding, offshore structures, and marine equipment. However, it is important to ensure that the steel used is specifically designed for marine environments to prevent corrosion and maintain the integrity of the equipment.

- Q: Can steel round bars be bent or formed into different shapes?

- Yes, steel round bars can be bent or formed into different shapes through various processes such as hot or cold bending, machining, or using specialized equipment like a pipe bender or a press brake.

- Q: What are the advantages of using nickel-cobalt alloy steel round bars?

- There are several advantages of using nickel-cobalt alloy steel round bars: 1. High Strength: Nickel-cobalt alloy steel round bars offer exceptional strength and toughness, making them suitable for applications that require heavy-duty performance. The addition of nickel and cobalt enhances the overall strength and hardness of the steel, allowing it to withstand high stress and pressure. 2. Corrosion Resistance: Nickel-cobalt alloy steel possesses excellent resistance to corrosion and oxidation. This makes it a preferred choice in environments where exposure to moisture, chemicals, or harsh weather conditions is common. The alloy's resistance to corrosion ensures durability and longevity, reducing the risk of rust or deterioration. 3. Heat Resistance: Nickel-cobalt alloy steel round bars exhibit superior heat resistance properties. They can withstand high temperatures without losing their structural integrity, making them suitable for applications involving heat treatment, such as forging or welding. This heat resistance ensures that the bars maintain their mechanical properties even under extreme thermal conditions. 4. Wear Resistance: The combination of nickel and cobalt in the alloy enhances its wear resistance. Nickel-cobalt alloy steel round bars exhibit excellent resistance to abrasion, erosion, and fatigue, making them ideal for applications in industries such as mining, construction, and automotive, where wear and tear are common. 5. Machinability: Nickel-cobalt alloy steel round bars are relatively easy to machine and fabricate. This makes them suitable for various manufacturing processes, including cutting, drilling, and shaping. The alloy's machinability allows for efficient production and reduces manufacturing costs. 6. Versatility: Nickel-cobalt alloy steel round bars have a wide range of applications due to their versatile properties. They can be used in industries such as aerospace, marine, oil and gas, automotive, and power generation. The alloy's combination of strength, corrosion resistance, and heat resistance makes it adaptable to diverse environments and demanding applications. In summary, nickel-cobalt alloy steel round bars offer numerous advantages, including high strength, corrosion resistance, heat resistance, wear resistance, machinability, and versatility. These properties make them a preferred choice for various industrial applications, ensuring durability, reliability, and performance.

Send your message to us

Mould Steel Round Bar 1.2379

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords