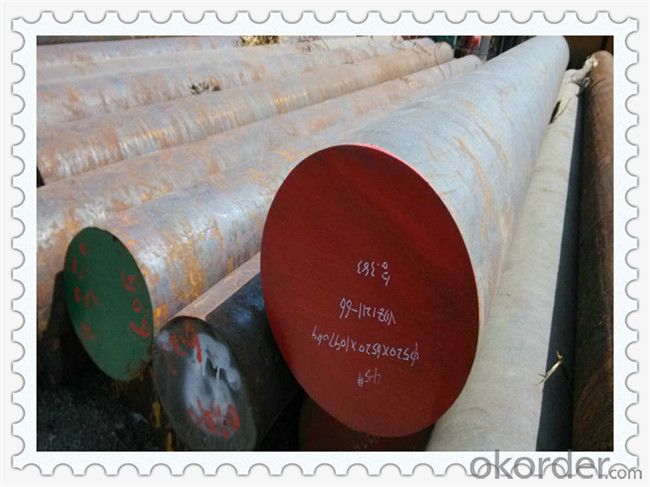

12L14 Steel Free Cutting Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

12L14 Steel Free Cutting Steel Round Bar

Specifications

1. Material:12L14

2. Size: 0.2mm-16mm

3. Stable quality

4. Competitive price

We own the eight profassion engineers of high strength steel wire,and five QC to keep the products good quality so that in oversea marketing .we have been getting good reputation for over 10 years.

Next we introduce the products as follows:

1. Steel grade: 12L14; SUM24L.

2. Diameter: 0.2mm-16mm.

3. Application: machinery, mechanical parts, instruments, auto parts and so on.

4. Tolerance standard: h8; h9, h10; h11.

Chemical composition& Tolerance

| Grade | JIS | C | Si | Mn | P | S | Pb |

| 12L14 | SUM24L | 0.15max | 0.15-0.35 | 0.85-1.15 | 0.04-0.09 | 0.26-0.35 | 0.10-0.35 |

| S25CL | 0.22-0.28 | 0.15-0.35 | 0.30-0.6 | 0.03max | 0.035max | 0.10-0.35 | |

| S45CL | 0.42-0.48 | 0.15-0.35 | 0.60-0.9 | 0.03max | 0.035max | 0.10-0.35 | |

| 1215 | SUM23 | 0.09max | 0.75-1.05 | 0.04-0.09 | 0.26-0.35 | ||

| SUN25 | 0.15max | 0.90-1.40 | 0.07-0.12 | 0.30-0.40 | |||

| Tolerance | |||||||

| Range | H8 | H9(Round bar) | H10(Hexagonal bar) | H11 | H12 | ||

| <3mm | 0-0.014 | 0-0.025 | 0-0.040 | 0-0.060 | 0-0.10 | ||

| 3-6mm | 0-0.018 | 0-0.030 | 0-0.048 | 0-0.075 | 0-0.12 | ||

| 6-10mm | 0-0.022 | 0-0.036 | 0-0.058 | 0-0.090 | 0-0.15 | ||

| 10-18mm | 0-0.022 | 0-0.043 | 0-0.070 | 0-0.11 | 0-0.18 | ||

| 18-30mm | 0-0.033 | 0-0.052 | 0-0.084 | 0-0.13 | 0-0.21 | ||

| 30-50mm | 0-0.039 | 0-0.062 | 0-0.100 | 0-0.16 | 0-0.25 | ||

- Q: Can I use steel bar instead of steel bar?

- Important stress parts should not be adopted. Reinforced surface made of thread, herringbone bond force is increased to crescent, steel and concrete, reinforced some parts if it is ends with a ribbed design can not bend, it is possible to design directly paste up, it is best to ask the design unit.

- Q: How are steel round bars used in the manufacturing of heat exchangers?

- Steel round bars are commonly used in the manufacturing of heat exchangers as they provide structural support and durability to the equipment. These bars are often used as the framework or as internal support for the heat exchanger's core, ensuring stability and longevity. Additionally, steel round bars can be machined or formed into various shapes to accommodate specific design requirements, allowing for efficient heat transfer and optimal performance of the heat exchanger.

- Q: Can steel round bars be used for making transmission towers?

- Yes, steel round bars can be used for making transmission towers. Steel round bars are strong, durable, and have excellent load-bearing capabilities, making them suitable for supporting the weight and structure of transmission towers.

- Q: Can steel round bars be coated with protective finishes?

- Steel round bars can indeed have protective finishes applied to them. Applying protective finishes to steel round bars is a widespread practice aimed at improving their durability and resistance to corrosion. There are several options available for protective finishes, such as galvanizing, powder coating, and epoxy coating, among others. These finishes effectively safeguard the steel bars against rust and deterioration, thus prolonging their lifespan and enabling them to perform well in different environments. The selection of a protective finish depends on various factors, including the intended use of the steel round bars, the extent of exposure to moisture or corrosive substances, and the desired aesthetic appeal.

- Q: Are steel round bars suitable for heat exchanger applications?

- Heat exchanger applications can benefit from the use of steel round bars. Steel is a widely utilized material in various industries, including heat exchangers, because of its exceptional thermal conductivity and strength. The round shape of the bars simplifies their fabrication and installation in heat exchanger systems. For applications requiring heat exchange, like power plants, chemical processes, HVAC systems, and refrigeration units, steel round bars are ideal as they efficiently transfer heat between two fluids. Moreover, steel provides good corrosion resistance, which is crucial for heat exchangers that encounter different fluids. By implementing proper design and material selection, steel round bars can reliably withstand high temperatures and pressure differentials in heat exchanger applications.

- Q: Can steel round bars be used for making conveyor belts?

- No, steel round bars are not typically used for making conveyor belts. Conveyor belts are usually made from materials such as rubber or fabric, which provide flexibility and durability necessary for conveying items efficiently.

- Q: What is the red hardness of a steel round bar?

- The red hardness of a steel round bar refers to its ability to maintain hardness and resist deformation at high temperatures, typically around 500°C to 600°C. This property is crucial for applications involving cutting tools and high-temperature environments.

- Q: Can steel round bars be used for making kitchen utensils?

- Kitchen utensils can indeed be made using steel round bars. Steel, being a robust and long-lasting material, is frequently employed in the manufacturing of kitchen utensils because of its ability to withstand corrosion, heat, and chemical harm. By effortlessly shaping and molding steel round bars, they can be transformed into a variety of utensils like spoons, forks, knives, and ladles. Moreover, steel utensils are non-reactive, ensuring that they do not release any harmful substances into food, thereby offering a safe option for cooking and food preparation.

- Q: What is the difference between gcr12 round bar and Cr12 round bar? Can it be used in general?

- The two are different in chemical composition.Cr12 is a widely used cold work die steel. It has high strength, good hardenability and good wear resistance, but its impact toughness is poor. The content of Cr was 11.50 ~ 13. The utility model is mainly used for cold punching dies and punches, cold cutting shears, drill sleeves, gauges, wire drawing dies, coining dies, drawing dies, drawing dies and thread rolling dies, which have the advantages of small impact load, high abrasion resistance, and high abrasion resistance.

- Q: Can steel round bars be used in the transportation industry?

- Steel round bars are indeed applicable to the transportation industry due to their strength and durability. They possess qualities that make them well-suited for transportation applications, where safety, reliability, and load-bearing capacity are crucial. In this sector, steel round bars serve various purposes, including the construction of vehicle frameworks, the production of axles, drive shafts, suspension components, and other critical parts. The exceptional tensile strength of steel ensures that these components can endure heavy loads and vibrations, making them appropriate for use in trucks, buses, cars, trains, and other modes of transportation. Furthermore, steel round bars can be easily machined and fabricated into different shapes, enabling customization and adaptation to specific transportation requirements.

Send your message to us

12L14 Steel Free Cutting Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords