M2 Steel Flat Bar for Tool Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

M2 Steel Flat Bar for Tool Steel

Product description:

Size of M2 high speed steel | |||||||||

Round bar | Diameter(mm) | Length (mm) | |||||||

Max:800 | Max: 9000 | ||||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | ||||||

Max:800 | Max:1000 | Max:6000 | |||||||

The specification can be customized. | |||||||||

Chemical Compositons | |||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | W | V |

W6o5Cr4V | 0.80-0.90 | 0.20-0.45 | 0.15-0.40 | ≤0.03 | ≤0.03 | 3.80-4.40 | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 |

M2 | 0.78-0.88 | 0.20-0.45 | 0.15-0.45 | ≤0.03 | ≤0.03 | 3.75-4.50 | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 |

1.3343 | 0.80-0.88 | ≤0.45 | ≤0.40 | ≤0.03 | ≤0.03 | 3.80-4.50 | 4.70-5.20 | 5.90-6.70 | 1.70-2.10 |

SKH51 | 0.80-0.88 | ≤0.45 | ≤0.40 | ≤0.03 | ≤0.03 | 3.80-4.50 | 4.70-5.20 | 5.90-6.70 | 1.70-2.10 |

Features of M2 high speed steel

1, General purpose of tungsten molybdenum high speed steel; | |||||||||

2, High toughness combined with good cutting powers; | |||||||||

3, Will withstand increases in temperature. |

Typical Applications:

1, Twist drills, reamers, broaching tools, taps, milling tools; | |||||||||

2, Cold forming tools and cutting tools; | |||||||||

3, Plastic moulds with elevated wear resistance and screws.

Packing: silver bright steel packaging : coated with anti-rust oil -plastic film winding -woven cloth winding- -strip steel strapping-wood shipping:according to contract content

|

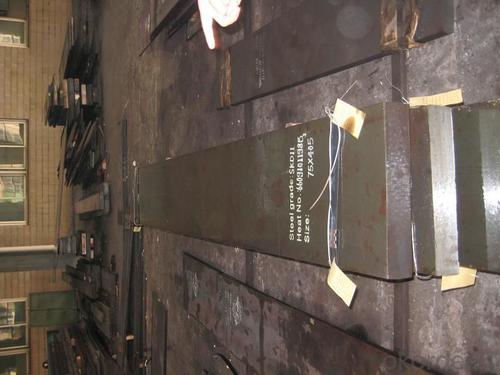

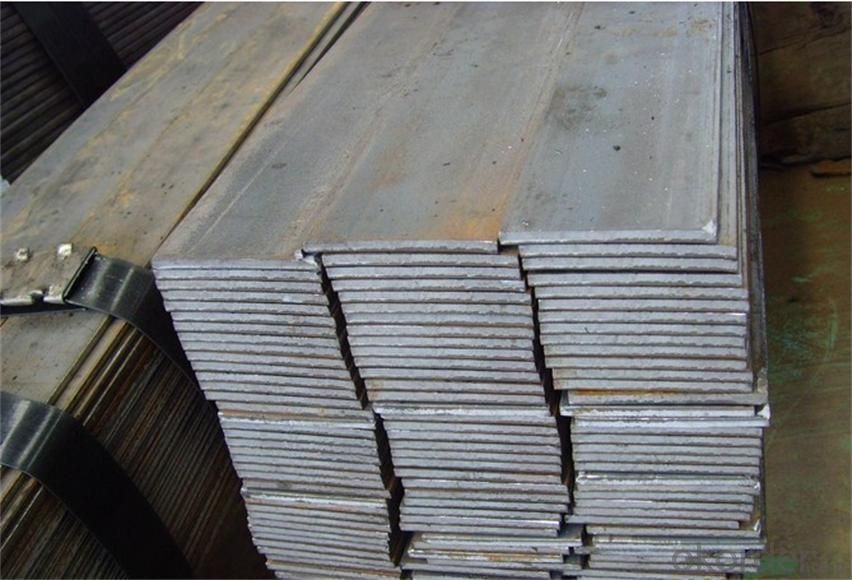

Products show:

- Q: What are the main factors affecting the formability of special steel?

- The main factors affecting the formability of special steel include the composition of the steel, its microstructure, temperature, strain rate, and the presence of impurities or defects. These factors influence the ability of the steel to deform without cracking or fracturing during the forming process. Additionally, the mechanical properties, such as the yield strength and ductility, also play a significant role in determining the formability of special steel.

- Q: Is special steel resistant to wear and abrasion?

- Indeed, special steel is renowned for its exceptional resistance against wear and abrasion. Through the utilization of distinct alloying elements and heat treatment procedures, special steel is frequently crafted to elevate its hardness and toughness. These remarkable attributes confer upon it a remarkable immunity to the damaging consequences of wear and abrasion, rendering it ideal for endeavors necessitating longevity and durability. In various industries, including automotive, aerospace, construction, and manufacturing, special steels are frequently employed due to the harsh environments they encounter or the repetitive mechanical actions they endure, both of which can induce wear and abrasion.

- Q: How does special steel contribute to the energy industry?

- Special steel plays a crucial role in the energy industry by providing high-strength, corrosion-resistant materials that are essential for various applications. It is used in the construction of power plants, oil and gas pipelines, and offshore drilling platforms, ensuring the structural integrity and reliability of these critical infrastructure. Special steel also enables the production of more efficient wind turbines and solar panels, enhancing their performance and durability. Additionally, it is utilized in the manufacturing of equipment used in nuclear power plants, where its unique properties ensure safety and long-term operation. Overall, special steel is a vital component in the energy industry, supporting its growth, sustainability, and technological advancements.

- Q: What are the different pharmaceutical grades of special steel?

- There are various pharmaceutical grades of special steel that are specifically designed and produced to meet the stringent requirements of the pharmaceutical industry. These grades are used in the manufacturing of equipment, instruments, and components that come into direct contact with pharmaceutical products. The different pharmaceutical grades of special steel include: 1. 316L Stainless Steel: This grade is widely used in pharmaceutical applications due to its excellent corrosion resistance and high purity. It is often referred to as surgical stainless steel and is suitable for parts that require frequent cleaning and sterilization. 2. 304 Stainless Steel: This grade is also commonly used in the pharmaceutical industry for its corrosion resistance and ease of fabrication. It is suitable for equipment and components that do not require as frequent cleaning or sterilization. 3. Duplex Stainless Steel: This grade offers a combination of high strength and corrosion resistance, making it suitable for applications where durability and reliability are key. It is often used in pharmaceutical processing equipment that handles aggressive chemicals or high-pressure environments. 4. Hastelloy: This is a nickel-based alloy that exhibits superior resistance to corrosion, heat, and chemicals. It is commonly used in pharmaceutical applications where extreme conditions are present, such as in reactors or vessels that handle highly corrosive substances. 5. Titanium: Although not technically steel, titanium is often considered a pharmaceutical-grade material due to its excellent biocompatibility and corrosion resistance. It is used in medical implants and devices, as well as in pharmaceutical equipment that comes into contact with sensitive drugs. These pharmaceutical grades of special steel are carefully selected based on their specific properties and suitability for pharmaceutical applications. They are manufactured and tested to ensure compliance with industry standards and regulations, such as Good Manufacturing Practices (GMP) and the United States Pharmacopeia (USP). Using the appropriate grade of steel in pharmaceutical manufacturing helps to ensure product safety, quality, and integrity.

- Q: Can special steel be used in mining applications?

- Yes, special steel can be used in mining applications. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as increased strength, durability, and resistance to wear and corrosion. These properties make it highly suitable for various mining applications where the equipment and machinery are subjected to extreme conditions, including heavy loads, abrasive materials, and exposure to water or chemicals. In mining, special steel is commonly used for manufacturing drill bits, cutting tools, crushing and grinding equipment, conveyor belts, and structural components of mining machinery. For example, drill bits made from special steel alloys have improved hardness and toughness, allowing them to effectively penetrate hard rock formations. Similarly, crushing and grinding equipment that utilizes special steel components can withstand the high stress and impact forces encountered during the extraction and processing of minerals. Moreover, special steel alloys provide better resistance to corrosion and wear, which are common challenges in mining environments. This helps to extend the lifespan of mining equipment, reduce maintenance costs, and enhance operational efficiency. Additionally, special steel can be tailored to meet specific requirements, allowing manufacturers to optimize the performance of mining equipment for different mining applications and conditions. Overall, the use of special steel in mining applications offers numerous benefits in terms of improved performance, durability, and cost-effectiveness. Its unique properties make it an essential material in mining operations, enabling the extraction and processing of minerals in a more efficient and sustainable manner.

- Q: How does special steel perform in food processing applications?

- Special steel is widely used in food processing applications due to its unique properties and benefits. One of the key advantages of special steel in this industry is its exceptional corrosion resistance. Food processing involves exposure to various corrosive substances such as acids, alkalis, and salt solutions. Special steel, such as stainless steel, has a high chromium content that forms a protective oxide layer on its surface, preventing corrosion and ensuring the hygiene and safety of the processed food. Furthermore, special steel is highly durable and resistant to wear and tear. Food processing equipment often undergoes rigorous and repetitive operations, such as cutting, grinding, and mixing. Special steel's high strength and toughness allow it to withstand these demanding applications without compromising its performance or integrity. This durability ensures a longer lifespan for the equipment, minimizing downtime and maintenance costs. Special steel also offers excellent heat resistance, making it suitable for high-temperature food processing applications. It can withstand extreme temperatures without losing its mechanical properties, maintaining its structural integrity and preventing any contamination risks. Moreover, special steel is easy to clean and maintain, which is crucial in the food processing industry. Its smooth surface and non-porous nature prevent the accumulation of food particles, bacteria, and other contaminants, ensuring a high level of hygiene. Special steel is also resistant to chemical cleaning agents and can be easily sterilized, making it an ideal material for food processing equipment. In summary, special steel performs exceptionally well in food processing applications due to its corrosion resistance, durability, heat resistance, and ease of maintenance. Its properties contribute to the safety, efficiency, and longevity of food processing equipment, ensuring high-quality and hygienic food production.

- Q: Can special steel be used in the semiconductor manufacturing industry?

- Yes, special steel can be used in the semiconductor manufacturing industry. Special steel alloys with high levels of purity and specific properties, such as high thermal conductivity and resistance to corrosion, can be utilized in various applications within semiconductor manufacturing, including the fabrication of specialized tools, equipment, and components.

- Q: How are copper alloys used in electrical applications?

- Copper alloys are widely used in electrical applications due to their excellent electrical conductivity and thermal conductivity properties. These alloys, such as brass and bronze, are used in the production of electrical connectors, terminals, and conductors. They are also utilized in circuit breakers, switches, and motors due to their high strength and corrosion resistance. Additionally, copper alloys are used in the manufacturing of electrical cables and wiring systems, ensuring efficient transmission of electricity with minimal power loss.

- Q: What are the properties of boron steel?

- Boron steel, also known as boron-alloyed steel, possesses several unique properties. It is exceptionally strong and has a high tensile strength, making it ideal for applications that require high-strength materials. Boron steel also exhibits good hardenability, meaning it can be hardened by heat treatment processes such as quenching and tempering. Additionally, it has excellent wear resistance and is often used in the manufacturing of cutting tools and wear-resistant components. Moreover, boron steel offers good weldability and formability, allowing it to be easily shaped and joined. Overall, the properties of boron steel make it a valuable material in various industries, including automotive, construction, and tool manufacturing.

- Q: Can special steel be used in the packaging industry?

- Yes, special steel can be used in the packaging industry. Special steel alloys, such as stainless steel, offer excellent durability, corrosion resistance, and strength, making them suitable for manufacturing packaging materials and machinery. They are commonly used in producing containers, drums, cans, and machinery components for packaging applications.

Send your message to us

M2 Steel Flat Bar for Tool Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords