All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

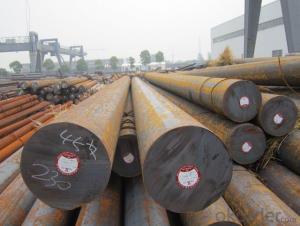

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the challenges in maintaining the integrity of special steel components in harsh chemical environments?

Maintaining the integrity of special steel components in harsh chemical environments poses several challenges. Firstly, these environments can subject the steel to corrosion, leading to material degradation and loss of strength. Secondly, the presence of aggressive chemicals can cause stress corrosion cracking, which weakens the structural integrity of the components. Additionally, the high temperatures in some chemical processes can accelerate wear and tear on the steel, further compromising its integrity. Moreover, selecting the right alloy and properly designing the components to withstand the specific chemical environment is crucial but requires extensive knowledge and expertise. Overall, the challenges lie in preventing corrosion, mitigating stress corrosion cracking, managing high temperatures, and ensuring appropriate material selection and design to maintain the integrity of special steel components in harsh chemical environments.

How is steel used in the construction of modern public transportation systems, such as subways?

Steel is used extensively in the construction of modern public transportation systems, including subways, due to its strength, durability, and versatility. It is used in the structural framework and support systems of subway stations, tunnels, and bridges. Additionally, steel is utilized in the fabrication of subway cars and rail tracks, ensuring safe and efficient transport for commuters.

What is the significance of high-speed steel in the manufacturing of cutting tools?

High-speed steel is significant in the manufacturing of cutting tools because it possesses exceptional hardness, toughness, and heat resistance. It allows cutting tools to maintain their sharpness and durability even when exposed to high temperatures during machining processes. This material enables cutting tools to efficiently cut through various metals and materials, thereby enhancing productivity and reducing tool wear and breakage.

What are the environmental considerations in special steel production?

Some of the key environmental considerations in special steel production include the consumption of energy and raw materials, carbon emissions, water usage, waste generation, and the potential for pollution. Special steel production processes often require high energy inputs and the consumption of various raw materials, which can have significant environmental impacts. The production of carbon steel, for example, is known to result in substantial carbon dioxide emissions, contributing to climate change. Water usage is another concern, as steel production requires large amounts of water for cooling and other purposes. Additionally, waste generation, such as slag and dust, can pose challenges for proper disposal and management. Overall, minimizing the environmental footprint of special steel production requires adopting cleaner technologies, improving energy efficiency, reducing emissions, optimizing water usage, and implementing effective waste management practices.

Wholesale Special Steel from supplier in Iraq

Whether you are in need of high-quality Special Steel for construction, manufacturing, or any other industry, we have you covered. Our team of experts is trained to provide personalized sales assistance, ensuring that you find the right Special Steel product for your specific requirements.

In addition to our sales services, we also offer competitive quotations to ensure that you receive the best value for your investment. Our dedicated technical support team is available to answer any questions you may have and provide guidance throughout the procurement process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to handle large-scale projects while maintaining a high level of customer satisfaction. Our strong relationships with global suppliers enable us to source Special Steel products of the highest quality at competitive prices.

With our extensive experience in the Iraqi market, we understand the unique challenges and requirements of doing business in the region. We can provide valuable insights and expertise to help you navigate the local market and ensure the success of your projects.

At our company, we are committed to delivering convenient and efficient one-stop procurement solutions for Special Steel products in Iraq. Contact us today to learn more about how we can meet your Special Steel needs and support your business goals.

In addition to our sales services, we also offer competitive quotations to ensure that you receive the best value for your investment. Our dedicated technical support team is available to answer any questions you may have and provide guidance throughout the procurement process.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to handle large-scale projects while maintaining a high level of customer satisfaction. Our strong relationships with global suppliers enable us to source Special Steel products of the highest quality at competitive prices.

With our extensive experience in the Iraqi market, we understand the unique challenges and requirements of doing business in the region. We can provide valuable insights and expertise to help you navigate the local market and ensure the success of your projects.

At our company, we are committed to delivering convenient and efficient one-stop procurement solutions for Special Steel products in Iraq. Contact us today to learn more about how we can meet your Special Steel needs and support your business goals.