All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

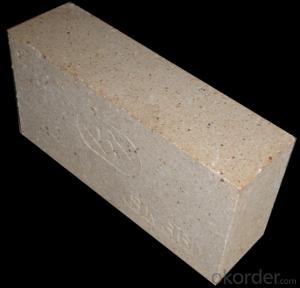

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common refractory materials used for lining crucibles?

The common refractory materials used for lining crucibles include graphite, alumina, silica, zirconia, and magnesia.

How do refractory materials prevent contamination in food processing operations?

Refractory materials prevent contamination in food processing operations by providing a heat-resistant barrier that prevents the transfer of contaminants from the surrounding environment to the food. These materials are designed to withstand high temperatures, chemical exposure, and physical wear, ensuring that they do not break down or release harmful substances that could contaminate the food. Additionally, refractory materials have smooth, non-porous surfaces that are easy to clean and sanitize, further minimizing the risk of contamination.

What are the common types of refractory plastics?

The common types of refractory plastics include silicon carbide, alumina, zirconia, and mullite-based plastics.

What are the challenges faced by refractory materials in the pulp and paper industry?

Refractory materials face several challenges in the pulp and paper industry. One major challenge is the exposure to high temperatures and corrosive chemicals used in the production process. This can cause degradation and erosion of the refractory materials over time. Additionally, the abrasive nature of the raw materials used in pulp and paper production can lead to wear and tear of the refractory linings. Furthermore, the frequent shutdowns and start-ups of the production equipment can put stress on the refractory materials, leading to cracks and failures. Overall, the challenges faced by refractory materials in the pulp and paper industry revolve around maintaining their integrity and durability in harsh operating conditions.

Wholesale Refractory Materials from supplier in Iraq

With our expertise and affiliation with CNBM, a Fortune Global 500 company, we are able to provide a comprehensive solution for all your Refractory Materials requirements in Iraq. Our wide range of products, combined with our sales, quotation, and technical support services, make us the top choice for customers in the region.

We understand the unique challenges and requirements of working in Iraq, and our years of experience in the market have given us valuable insights and expertise. We are well-equipped to provide you with the necessary support and guidance to ensure the success of your projects.

When you choose us as your partner, you can expect high-quality products, exceptional customer service, and reliable technical support. We are dedicated to delivering the best solutions for your Refractory Materials needs and helping you achieve your goals in Iraq.

Contact us today to learn more about our products and services and how we can assist you in your projects.

We understand the unique challenges and requirements of working in Iraq, and our years of experience in the market have given us valuable insights and expertise. We are well-equipped to provide you with the necessary support and guidance to ensure the success of your projects.

When you choose us as your partner, you can expect high-quality products, exceptional customer service, and reliable technical support. We are dedicated to delivering the best solutions for your Refractory Materials needs and helping you achieve your goals in Iraq.

Contact us today to learn more about our products and services and how we can assist you in your projects.

Hot Search

- Monolithic Refractories in Slovakia

- Ceramic Fiber Products in Mozambique

- Refractory Bricks in Albania

- Raw Materials For Refractory in Senegal

- Refractory Bricks in Iceland

- Ceramic Fiber Products in Papua New Guinea

- Raw Materials For Refractory in Egypt

- Refractory Bricks in Thailand

- Refractory Bricks in Grenada

- Refractory Bricks in Serbia