Beautiful Wood Veneers:Bamboo/Wood Engineered Veneer - Eco Building Material for Natural Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Build i200™ Series | Bamboo Veneer

Description

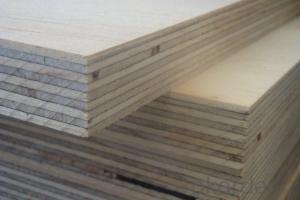

Using Bamboo as a material to renovate your house or for furniture purposes is just a brilliant idea. In many countries, bamboo is utilized as a building material. Bamboo veneer is a great choice because it helps in sustaining all your furniture in the future. Since bamboo grows fast, it is a much eco-friendly choice for everyone to make. Though is more difficult to produce than conventional solid wood veneers, due in part to the number of glue joints that reduce yield but the longevity is worth. Bamboo veneers are suitable for any interior application such as wall, ceiling, furniture covering, furniture production etc.

| Material | Dimensions |

Solid engineered bamboo Adhesive: Non-Toxic, Low V.O.C. adhesives (LEED Credit Certified) Fire Rating: International Class B | Thickness: 0.5mm, 1mm, 6mm Width x Length: 610mm x 1220mm 1220mm x 2440mm Custom Available |

| Surface | Application |

Grain: Vertical / Edge Grain Horizontal / Flat Grain Strand Woven Grain Color: Natural colours Custom stained | Furniture covering Ceiling Wall decoration

|

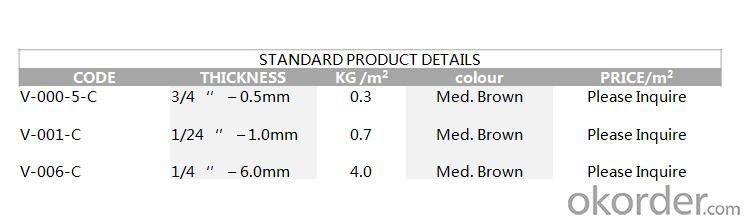

Build i200™ Series | Bamboo Veneer | Standard Product Pricing List

Note

1. Standard board sizes, 610*1220, 1220*2440 mm (width* length). Custom sizing is available, please inquire.

2. Edge profile subject to product dimension

3. Available lay-ups for different thickness.

Build 200™ Series | Standard Product Details

Panel Details:

1. All pricing is based on net coverage and includes standard packaging.

2. Minimum quantities may be required for certain panel dimensions and/or colours. Please Inquire.

3. All pricing is based on med. brown (carbonized) color, Please see colour chart for available standard colours. Special colours are available, please inquire.

4. Certain series material are available in a vertical and horizontal grains only. See lamination lay-up chart for details.

5. Custom thickness, widths, lengths are available, please inquire.

Surface Treatment Details:

1.The surface treatment are environmentally friendly and can contribute to a projects LEED or other environmental certifications. Please inquire.

Packaging Details:

1. Standard packaging: Plywood are stacked with EVE protective film interleafing and strapped. Secured on each side with 6.35mm plywood and blocked for shipping protection. Each package is wrapped with PP weather protective covering, and palletized.

2. Optional ECO packaging available. Please inquire.

3. LCL shipments require increased plywood crating with micro-foam interleafing.

4. International shipments ................................ Please inquire.

5. Special packaging ........................................ Please inquire

Shipping Details:

1. Mainland China....................................... Please inquire

2. Other Country or Area............................. Please inquire

Delivery Details:

1. 0.6mm- stocked Med. Brown (carbonized) ....................Please inquire

2. Other dimensions, colors and lay-ups .......................45days + shipping

Notes:

1. All panel lengths over 1220*2440mm....................................Please inquire

2. Limitations may apply to certain lay-ups.

3. All sizes subject to 0.0625 inch (1.3mm) tolerance.

4. Installation of material constitutes acceptance. It is the customer's responsibility to check received product(s) from us before signing the freight carrier's paper work to ensure no damage has occurred to the finished product(s) during transit. If the customer signs off on the delivered product(s) before checking finished product(s) and damages have occurred due to transportation, It will not be our responsibility to replace any damaged product(s).

Grain Surface Detail

Vertical

Horizontal

Strand

Vertical Series

VSP – Vertical Solid Ply

Unidirectional Laminated Ply(s)

VCP –Vertical Cross Ply

Cross Laminated Ply(s)

Horizontal Series

HSP – Horizontal Solid Ply

Unidirectional Laminated Ply(s)

HCP – Horizontal Cross Ply

Cross Laminated Ply(s)

Strand Series

SCP – Strand Cross Ply

Cross Laminated Ply(s)

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- Let's talk about natural veneer. Natural veneer regardless of pattern or texture than the wood to do the effect of furniture

- Q: How to seize the key to solve the problem of slow development of paste veneer process?

- Under normal circumstances, the designer is the use of Wan Nengjiao and white latex, and these two kinds of glue has a great flaw

- Q: A lot of Advantages of veneer

- Apply white glue to the surface of the applied wood. The veneer will be affixed to the surface of the wood, and plastic scraper along the veneer lines scrape out the bubble

- Q: Cut Slicing - The cut is a round of vertical cut logs, producing a veneer with a ruled ridge.

- To cut the oak-like wooden vines at a slight angle, to minimize the appearance of "scales" of wood grain, to produce a ruled veneer.

- Q: Paste veneer craft specifically refers to what

- thus affecting the appearance of furniture, the product quality greatly reduced. In order to solve this technical problem

- Q: Slicing of thin slices of wood

- after cooking treatment; the cooking process should be reduced to more than 40 ℃, it should slow down the heating rate

- Q: Part of the production process

- This is the actual production is usually used saturated steam or hot water on the wood side of the cooking treatment of a water heat treatment reasons.

- Q: Wooden door with veneer ruled, pattern is produced by different cutting methods

- cut out the wood. From the cut off the logs cut off the veneer, the first layer of the ring will form a "cathedral" type of pattern grain.

- Q: Often, the processing of natural vines is done by slicing the method.

- The program is reasonable not only the high rate of production, and the system is made of chopped thin wood, chord thin wood, the resulting high value of decorative products.

- Q: Different cutting processes of wood veneer

- in 1965 in Italy and the United Kingdom have launched the earliest, domestic generally called" science and technology.

Send your message to us

Beautiful Wood Veneers:Bamboo/Wood Engineered Veneer - Eco Building Material for Natural Decoration

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords