Furniture Plywood/Bintangor Plywood/Okoume Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Furniture Plywood/Bintangor Plywood/Okoume Plywood

Specification

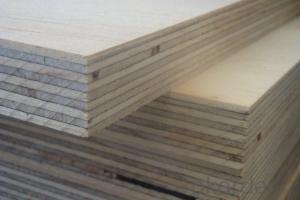

1.Size:1220*2440mm, 915*1830mm, 1250*2500mm , 1830*3100mm

2.Thickness:3.6-50mm

3.Tolerance:±0.1MM to ±0.5MM

4.Material

Core:Full poplar,full pine,full hardwood,full birch,and mixed core

Face/back:Normal brown black film or dynea brown film,red film.

Glue:MR,MELAMINE E1,E2,E0,WBP

Moisture:below12%

Grade:BB/CC, BB/BB, C/D, E/F, AAA, AA, A, A/B, DBB/CC, or as your requests

Feature:Wear-resistant, anti-cracking, and alkaline-resistant

MOQ:1*40 HQ

Advantage

1) lightweight: better be used for high building and bridge construction

2) No warp, no distortin, no cleft, well water -resistant, long playing used and recycled

3) Do concrete: beautiful and slippy surface, take out the second plaster, which can save 30%

working times

4) cauterization-resistant, the concrete surface with no polluting

5) well heat preservation, in favor winter construction

6) well construction capability

7). Re-use many times: It can be used for many times if stocked correctly

8). Good thermal insulation: It is good for construction in Winter that it can be used as

template for curved surface.

9). Good construction performance: It is better than bamboo plywood and small

steel plywood in terms of nailing, sawing and drilling, It can be processed to template

with all shapes according to needs

Payment:T/T or L/C

Packing:Inner with plastic bag, outside covered with plywood or cartons, then steel tapes for strength

Applications

furniture, building boards, transport industry and under flooring

- Q: Judging wood is the standard for plywood

- If you have an old piece of furniture, it is time to polish or throw it away, then you can make a decision by identifying the wood sometimes.

- Q: How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- It can be installed directly. It can be made of concrete frame structure and formwork.

- Q: The Decorative veneer veneer plywood grade classification

- China veneer veneer veneer plywood standard veneer veneer plywood is divided into excellent products, first-class goods and qualified three grades

- Q: What is the density of plywood?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences. Commonly used plywood type plywood, penta and so on

- Q: What is medium density fiberboard

- Plywood commonly known as three plywood, five plywood, nine PCT board, twelve PCT board and so on

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: What kind of glue is today's plywood?

- if you want the wood products have a stronger waterproof and moisture-proof performance, you can use E1 (or even E0) melamine glue.

- Q: What is the plywood made of wood?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: What are the shortcomings of plywood

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides

Send your message to us

Furniture Plywood/Bintangor Plywood/Okoume Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords