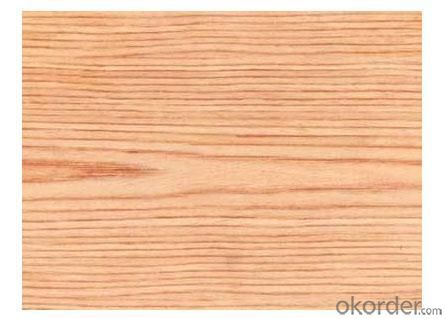

Exotic Wood Veneers - Natural Red Oak Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the natural red oak veneer

| Veneer size | 2200-3000*130+0.5 |

| Grade | A, B,C |

| Applications | furniture making, interior and exterior decoration |

| Species | red oak |

| Packing | standard exporting packing |

The advantages of the natural red oak veneer

A) high quality of the natural red oak veneer, no sound and dead knot, no hole and very clean

B) professtional team for your whole exporting process

C) moisture: to be 8-10% at time of shippment

D) various species and various colors to meet your requirements

E) the natural red oak veneer can make the furniture appear especially high grade

F) applied in the modern design and traditional classic design

other wood species for the natural veneer

White oak, teak, russian oak, sapeli, russian birch, american walnut, maple, cherry.

Application of the natural red oak veneer

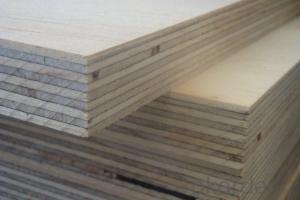

The cutting style of the natural red oak veneer is sliced or rotary cut, it is widly used in the furniture

making, interior and exterior decoration. Especially for face or back-fancy plywood, flooring. It is

stable supply for both crown and quarter.

The following pictures for reference

- Q: Veneer production process is this?

- After the wood side has been cooked (ie, water heat treatment), the plasticity of the wood increases

- Q: How to seize the key to solve the problem of slow development of paste veneer process?

- According to professional survey found that upgrading the veneer process not only to ensure the quality of veneer and production level, but also need a suitable veneer glue

- Q: A lot of Advantages of veneer

- The same mild touch as the logs. More economical than the logs, low prices. Easy to apply to all kinds of body, painting versatility.

- Q: Cut Slicing - The cut is a round of vertical cut logs, producing a veneer with a ruled ridge.

- Lengthwise Slicing - Cut the flat saws flat through the fixed slicer and cut the veneer from the bottom of the plate. The texture of the longitudinal cut veneer is varied.

- Q: What can the veneer be classified?

- according to the manufacturing method of classification Can be divided into sliced thin wood; peeling veneer; sawing thin wood; semi-circular peeling veneer. Often the use of slicing method

- Q: Often, the processing of natural vines is done by slicing the method.

- In the actual production, the diameter of less than 400mm of the logs are usually used Sawing program B, and the diameter of 400 ~ 800mm logs are used sawing D and E

- Q: What is veneer, please explain in detail

- after half a century of development, already have a considerable scale.

- Q: Veneer should pay attention to the different production processes

- But the technology veneer is widely recognized by the furniture industry still need time, science and technology on the wood of many misunderstandings, are the lack of factual basis, is the understanding of the errors.

- Q: The Production process of cooking

- water temperature is best to maintain room temperature, and slowly warming, so as to avoid the thermal stress caused by wood cracking

- Q: Different cutting processes of wood veneer

- in 1965 in Italy and the United Kingdom have launched the earliest, domestic generally called" science and technology.

Send your message to us

Exotic Wood Veneers - Natural Red Oak Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords