Real Wood Veneers Cherry Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

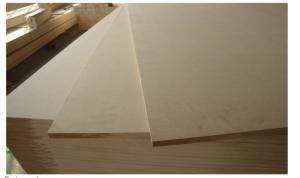

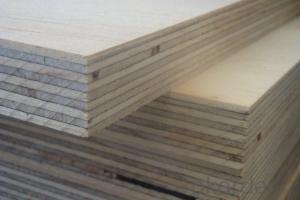

Specifications of the Cherry Engineered Wood Veneer

| Length | 2150-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-2.0mm |

| Normal size | 2500*640*05mm |

Instruction of the Cherry Engineered Wood Veneer

Engineered Veneer is a sliced reconstructed real wood veneer. It is made from natural timber

which color is enhanced, reformed to a square "log" and then re-sliced in rectangular veneer

sheets.

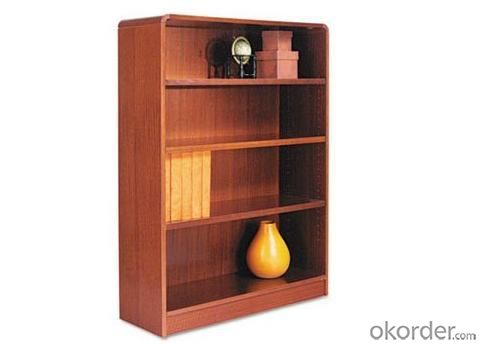

The usage of the Cherry Engineered Wood Veneer

It is widly applid in the following regions: door inserts, wall panels, ceiling panels, privacy

screens, architectural millwork, and furniture inlays, hotel, shopping mall, restaurtant, loung,

commercial space, chains, office, halll dinning, expo, column, furniture,slide door, interior door,

house, bar etc.

The main wood grain of Cherry Engineeres Wood Veneer includes

Teak, Oak, Elm, Wenge, Walnut, Cherry, Maple, Ash, Ebony, Zebrawood, Rosewood, Apricot,

Sapelli, Vine Burt etc.

The package of the Cherry Engineers Wood Veneer

Package details: Wood pallet packing and wrapped with waterproof plastic, then fixed by iron belt.

Delivery details: China main port and 7-30 days after we receive your deposit.

Engineered Wood Veneer are good used for furniture decoration

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- Let's talk about natural veneer. Natural veneer regardless of pattern or texture than the wood to do the effect of furniture

- Q: How to seize the key to solve the problem of slow development of paste veneer process?

- Under normal circumstances, the designer is the use of Wan Nengjiao and white latex, and these two kinds of glue has a great flaw

- Q: The Veneer dyeing quality requirements

- There are obvious texture, color, etc.), for the modern design to add rich colors.First of all, of course, there are veneer, from the selection of suitable veneer (some veneer due to the nature of the problem is

- Q: The following table lists the cooking criteria for several types of wood,

- intermittent operation of the drying room. Drying room is old-fashioned drying equipment, very economical, but dry quality is better.

- Q: Technology veneer and natural veneer distinction

- But it has a natural veneer than the advantages. That is not blistering. I think you should understand that. And its pattern of pattern.

- Q: Brief description of veneer production process

- First, the wooden side into the cooking pool, the tree species, wooden specifications should be carried out separately; water temperature is best to maintain room temperature, and slowly warming,

- Q: Often, the processing of natural vines is done by slicing the method.

- In the actual production, the diameter of less than 400mm of the logs are usually used Sawing program B, and the diameter of 400 ~ 800mm logs are used sawing D and E

- Q: Different veneer has different production processes

- Most furniture companies believe that science and technology veneer is not a native wood, but what is it, they also do not know, or simply called "artificial veneer".

- Q: Veneer should pay attention to the different production processes

- But the technology veneer is widely recognized by the furniture industry still need time, science and technology on the wood of many misunderstandings, are the lack of factual basis, is the understanding of the errors.

- Q: Different cutting processes of wood veneer

- because the technology veneer much attention, the question naturally a corresponding increase.Furthermore, the technology veneer is processed by the secondary processing of the original wood

Send your message to us

Real Wood Veneers Cherry Engineered Wood Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords