Wood Veneers and Solids Veneered Molded Door Skin

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 45000 PCS pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

The details of the Veneeres Molded Door Skin

| Desc. | surface | Thickness | Height(mm) | Width(mm) | N.W(KG) |

| Veneered Molded Door Skin,Mould the Medium density fiberboard to be raised panel with natural/engineerd veneer surface. | Natural ash or Natural Sapele or Tech.Sapele | 3.2mm | 2150 | 670 | 4.9 |

| 770 | 5.5 | ||||

| 850 | 5.9 | ||||

| 1020 | 6.5 | ||||

| Tech.Black walnut | 3.2mm | 2150 | 670 | 4.9 | |

| 770 | 5.5 | ||||

| 850 | 5.9 | ||||

| 1020 | 6.5 | ||||

| Tech. Teak or Tech.Cherry or Tech.white-washed white oak or Tech. Red Oak | 3.2mm | 2150 | 670 | 4.9 | |

| 770 | 5.5 | ||||

| 850 | 5.9 | ||||

| 1020 | 6.5 | ||||

| Natural Teak or Natural Red Oak or Tech. Cassia Siamea | 3.2mm | 2150 | 670 | 4.9 | |

| 770 | 5.5 | ||||

| 850 | 5.9 | ||||

| 1020 | 6.5 |

The advantages of the Veneer Molded Door Skin

1) Density: above 850 kg/m3

2) Moisture: 6 - 12%

3) Water absorption rate: <20%

4) Modulus of elasticity: ≥35Mpa

5) Tolerance:Length/width<2.0mm; thickness<0.2mm

The package of the Veneer Molded Door Skin

The packing is: 240pcs/pallet

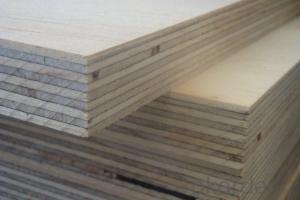

The following pictures for your reference

- Q: Veneer production process is this?

- The use of these saws to produce veneer, the board rate is high, the quality of thin wood is better, chopper machine is more efficient.

- Q: A lot of Advantages of veneer

- Apply white glue to the surface of the applied wood. The veneer will be affixed to the surface of the wood, and plastic scraper along the veneer lines scrape out the bubble

- Q: Paste veneer craft specifically refers to what

- Because of the existence of these defects, with the universal glue and white latex can not solve the arc-shaped furniture or furniture, arc parts of the bubble, cracking, overflow rubber and other issues

- Q: The following table lists the cooking criteria for several types of wood,

- intermittent operation of the drying room. Drying room is old-fashioned drying equipment, very economical, but dry quality is better.

- Q: Technology veneer and natural veneer distinction

- And now the technology veneer manufacturers are constantly improving the natural sense of science and technology veneer

- Q: The principle of veneer dyeing

- Dyed veneer: a new era of decorative materials, with the original natural wood processing and dyeing, without losing the natural wood characteristics (light color and natural texture),

- Q: The Production process of cooking

- The following table lists the cooking criteria for several types of wood, for reference only.

- Q: Veneer has a very affordable, versatile features

- but the natural veneer's unique texture and The characteristics of the technology can not match the veneer, therefore, natural veneer market demand is great.

- Q: What are the quality items of veneer piles?

- Each year round, by the pith part of the annual growth season is the initial formation, material color is shallow, loose tissue, material soft, called early wood (spring wood)

- Q: The Sliced ??veneer manufacturing process

- The width of the veneer is not less than the relevant requirement.

Send your message to us

Wood Veneers and Solids Veneered Molded Door Skin

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 45000 PCS pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords