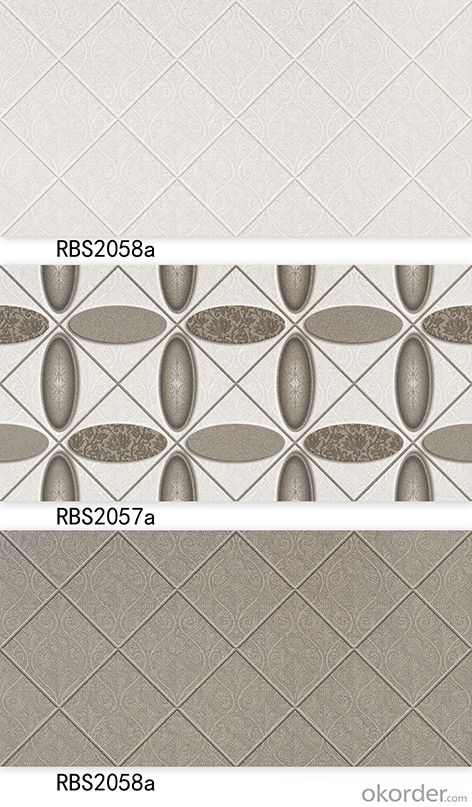

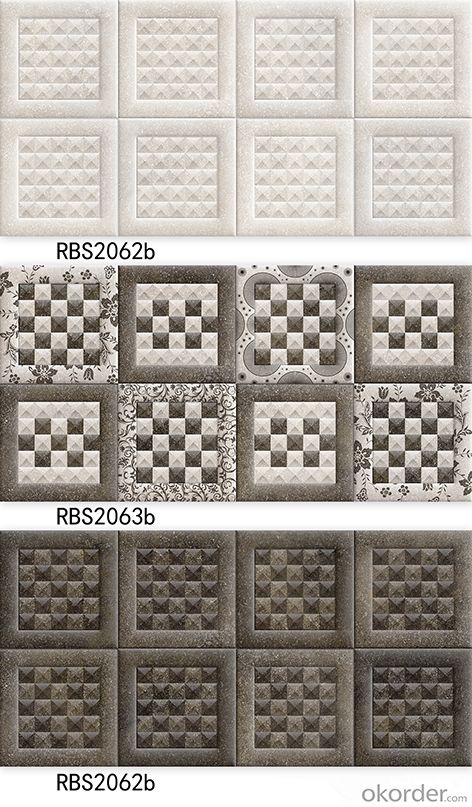

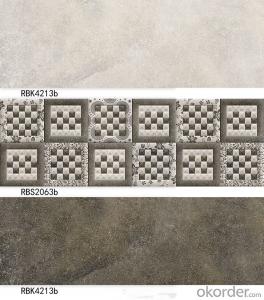

ceramic wall tiles for bathroom & kitchen for Dubai market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12300 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ceramic wall tiles for bathroom & kitchen for Dubai market

Advantage:

1. All ceramic wall tile are PREMIUM AAA Grade. We established an independent dept to inspect all goods before shipment.

2. OEM service: We can make your brand on the package or even on the tiles. Also, you can customize your own designs with us.

3. Special dimensions are available according to request.

4. More than ten years experience and very professional team in exporting to ensure your order more smooth.

5. On time delivery, in general 15~20 days.

6. Best service: customer can follow their order situation any time, no matter on product line, warehouse or shipment.

7. Own designer team ensure the designs are newest and adjust for pure and right color.

Detailed product description: | |

Model no: | HW000821 |

Tile type: | 300x600mm glazed ceramic wall tile |

Material: | ceramic |

Size(MM) : | 300*300mm,300*450mm,300*600mm,300*300mm,250*750mm,400*800mm |

Water absorption: | 14-16% |

Color: | Available in all designs and colors |

Usage: | Used for wall and floor, widely used in kitchen, bathroom, living room, and so on. |

Surface: | glazed polished |

Certificate: | CE & ISO9001, Test report |

Delivery time: | Within 20 days after received the deposit |

Payment terms: | L/C,T/T,WESTERN UNION |

MOQ: | 1000 square meters |

Package Details :

8 pcs/carton

1080 cartons/1*20 GP/with pallet

27 Ton/ 1*20 GP

Product effect:

Company information:

Our company founded in 2004,is a professional manufacturer of all types of ceramic tiles and porcelain tiles,covering an area of 180,000 square meters.Currently we have over 1000 staff,including 72 research & development talents with years'experience in this field.

With international advanced machines imported from Italy and Spain, we can provide tiles with superior quality standard. Our company obtained the ISO9001 Quality Management System Certificate,thereby ensuring that we can supply clients with a significant quality guarantee.

Moreover,we greatly pay attention to constant technical innovation.Over the past few years,we have developed a wide range of wall tiles and floor tiles.These products are available in 300*600mm,400*800mm,300*900mm,600*600mm ,800*800mmm ...

Factory show:

FAQ:

1. What is your MOQ?

MOQ: one design one container .

Decoration design: one design 1x20’GP, also can mix color in one container.

2. What is the MOQ to use customer design carton?

MOQ: 5x20'GP. if less than this qty will charge for carton design draft fee.

We have own designers to meet your requirements.

3. What is special of your tiles?

More glossy, more shine, more 170g glaze , special technology of tile body more stable.

4. How you assure the quality?

We inspect the quality during incoming material, production process, packing and loading.

5. Where is you market ?

Our main markets are North America , South America , Asia and Middle East .

6. Do you attend oversea fairs ?

Yes, we attend the fair in Dubai, Vietnam , Algeria , Korea ,Brazil and Frankfurt etc .

7. Can you make OEM ?

Yes ,we can .

8. Where is you famous customers ?

Our customers are including The Homedepot, OBI,...

9. What price you can offer?

EXW, FOB, CFR/CIF, ect

10. Do you have quality control team and designers?

Yes, we have 10 QC and 8 designers to guarantee quality and meet your colors and styles need

11. What payment you accept?

Normally By TT, L/C also acceptable.

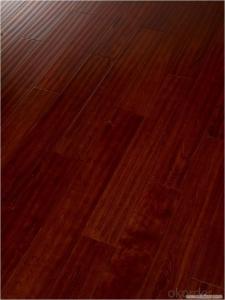

- Q: I live in a condo apartment on the 2nd floor. I want to soundproof the floor, but I don't want carpeting. Therefore, I glued a cork underlayment to a wood sub floor. Now, I want to glue the engineered wood floor to the cork underlayment. Is this reccomended?

- If your cork is down well and the glue you use will bond to the cork, your ok. Check out what type of glue your using. Most urethane based glues will work. GL

- Q: What is the preferred method of installing an engineered wood floor over a concrete slab? Float or glue & why?

- Yes you can, most of the new wood flooring are tongue and groove floating floors. Just be sure to buy a good underlay. Ask the flooring professionals at Lowes or Home Depot they will tell you what to do. If your tile is nice and flat and installed well it is almost just as good as installing on a concrete foundation (this is done on homes in Florida everyday!). Good luck to you, be sure to take your time and do a great job!

- Q: We are looking to put in about 600 sq of engineered hardwood floors in our house. What are some of the better brands out there. We heard Johnson hardwood is pretty good. Any thoughts?

- Bruce, Mohawk, Shaw, Bella Woods and Armstrong to name a few to get you started.Now remember each one ( and all ) of these will have a low end and a high end so shop apples to apples. As far as Johnson hard wood, I haven t heard either way with that particular one. GL

- Q: How to solve the deformation of solid wood flooring?

- To solve the problem of swelling and deformation of solid wood floor, here are the following for reference:A, ground moisture treatment methods: the general use of the "three oil felt" (three layers of asphalt asphalt felt paper, and then put a layer of cement on the top, to prevent the release of harmful gases); simple treatment method is to spread a layer of moisture-proof film on the surface of the two layers of asphalt.

- Q: Shop wood flooring home but very fragile. The family kept a puppy in the above pee pee I want to disinfect with Walch can? Specifically how to use? Trouble point!

- Daily use should pay attention to avoid the heavy metal, glass tiles, sharp spikes and hard objects scratch the floor; don't drag floor surface move move furniture; do not make contact with the fire floor or placed directly on the floor of large power heater; the prohibition of placing strong acid and alkaline substances on the floor; the absolute prohibition of water for a long time dip.

- Q: Is thickness a major concern with engineered hardwood flooring? My subfloor is 3/4 ply.Here's an example.

- The thicker products are always better. Also, the thicker the top wear layer is the better. The top wear ;layer will determine how many times the floor can be refinished in the future. Thicker floors also tend to feel more solid when walked on.

- Q: Oak and oak wood floors have what distinction

- Let a bedroom everywhere exudes a unique or fashion, or natural gas. At present the original decoration in the family, choose light color or color is close to the log floor has become a popular trend. Especially young users prefer this type of decoration and floor.

- Q: Solid wood floor care?

- Solid wood floor is not very good care, because small damage is not easy to repair, care should be more careful when.

- Q: How to identify the authenticity of solid wood flooring

- Panel: in the poor quality of solid wood substrate affixed to 0.05mm - 2mm thickness of solid wood veneer, in order to act as a pure solid wood flooring sales to deceive consumers. Because of this kind of floor from the substrate due to inferior quality is not stable, and will use the inferior wood veneer and pressed together with adhesive, easy to cause the peeling veneer and the substrate, and the existence of a formaldehyde content is not environmental protection.Identification method: can be observed through the comparison of the floor surface and the bottom of the identification, the surface of the wood floor and the ground is basically the same, and the panel is completely different.

- Q: The advantages and disadvantages of solid wood flooring and laminate flooring? Home decoration, I do not know what kind of good, experienced friends introduced! Thank you

- 2, wood floors Juegan comfortable, good insulation properties, is one of several kinds of materials in the most gentle and friendly, very suitable for the loving nature of the friends;3, rich varieties of wood, the original pattern of ecological, beautiful appearance.

Send your message to us

ceramic wall tiles for bathroom & kitchen for Dubai market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12300 m²

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords