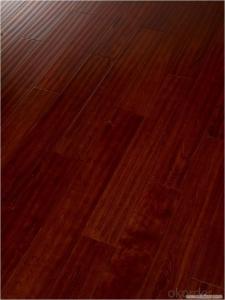

Yongsen Ash Wood A Class Pure Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Ash wood is of high quality, durable, flexible and beautiful pattern is heartwood tree, slightly pale yellow sapwood, heartwood pale brown heartwood gradually to the plate transition. All duct wall thickness, wood parenchyma around a small tube. Wood ray is fine, the number is much, the ring hole is light yellow. Because of the wood material is light, the system makes the furniture is also relatively light.

Dry wood is easy to dry, but dry time is long, the dry shrinkage of wood is medium. Dry shrinkage factor: the diameter of the 0.17%, the string contraction of 0.31%, in the rapid drying of wood cracking.

2、Product Characteristics

1, the section is very smooth, paint and adhesive properties are also very good. It is suitable for dry climate, and the aging is very mild, and the performance is small.

2, ash processing performance is very good, nails, screws and glue is fixed, and can by staining and polishing and surface effect is very good.

3, ash has a resilient material, beautiful texture, but also has very good overall strength, good resistance to earthquake and steam bending strength, is a good timber for making furniture.

4 and durability: heart wood of anticorrosion treatment agent has moderate anti penetration, white wood (sapwood), penetration, Fraxinus mandshurica is suitable for dry climate and its aging very slight, heartwood changes small

3、Parameter

Pattern: Wood

Special purpose: anti-corrosion

Plate finish: Class A

Surface shape: paint

Residual depression: 1

Formaldehyde release rate: E1

Resist pressure: 1

Wear layer thickness: 3mm

Wear resistance: premium

Fading (stage):1

Floor thickness: 18mm

4、Reference pictures

- Q: Because the house is to be demolished, the new solid wood flooring is not a pity, so I would like to ask if we can get the floor to the new premises again?

- Be careful when removing, most of which can be recycled

- Q: What is better for a townhouse we cannot do normal hardwood due to the concreet bottom so it's between engineered hardwood (Brazilian Cherry Br111) or the wood laminate(Pergo Brazilian Cherry). What's better?

- I just attended a Br111 product seminar and came away with a good impression. They are a small company and make a quality product. Engineered hardwood is going to look the same as solid hardwood the only difference being that it is made of 3, 5, or 7 layers of real wood instead of 1. It will look and feel much better than laminate, but is obviously more expensive. If you use engineered, I strongly suggest full glue down installation. This will give a very solid look and feel making the floor indistinguishable from solid hardwood. Floating, hardwoods have proven quite problematic so far. Most Br111 engineered products can be refinished 1 time, laminate can not. If you use laminate, Pergo is a good way to go, having a 25, or 30 year wear/stain/fade warranty.

- Q: Wood in 5 wide and 1/2 thick hand scraped birch. Manufacturer recommends 18 ga 1 1/4 staples with 1/4 crown.

- If the vinyl is layed directly over the wood sub floor then yes you ll be fine with that size staple. If the vinyl is atop a thin luan subfloor then go to 1 1/2 staple .The thinner 3/8ths wood take a 1 staple. . This is a special nailer (stapler) that you can rent. Takes some getting use to but works great for engineered wood. Any questions you can e mail me through my avatar. GL

- Q: What kind of solid wood floor

- High-grade wood: oak (220-420 yuan / square meters); jatoba (230-350 yuan / square meters), teak (270-420 yuan / square meters), Balsam (220-330 yuan / square meters of high-grade wood): Black Walnut (300-500 yuan / square meters), Asian Pear (300-450 yuan / square meters), and ebony, red sandalwood, rosewood, rosewood and other valuable timber wood flooring is made, the market price at least 500 yuan / square meters or more; (two) according to the characteristics of sales is good, affordable

- Q: Home decoration, intended to shop wood flooring three storey building materials city to see the floor, found a lot of solid wood flooring seller told me that the wood floor can be used wet mop, without wax today, not arching, good care and so on, this is really, the price is about 300. To 400 yuan or so, my question is always heard wood floors not wait on price...On the other hand, the solid wood flooring businesses have told me that when the floor is not playing keel, you can shop like a composite floor shop a moisture-proof pad directly after the shop, so good?

- Buy solid wood flooring. Don't listen to the people selling floor nonsense.Solid wood floor can use wet mop wipe, do not wax, not arch, good care, and so on, is this true? This is fake.

- Q: How to choose solid wood flooring?

- For half a pack of owners, but an important part of the floor material purchase, but also a heavy head home to spend, want to save money decoration, this one can not ignore, Xiao Bian summed up the floor to buy a practical knowledge for you, make you less than 5 minutes to save thousands of experts, is not a problem.

- Q: What is the difference between the overhead wooden floor and the solid wood floor

- The main difference is that the installation of overhead wood floors, the laying of the keel on the ground, keel and wood fixed, the actual shop is directly installed on the ground.

- Q: How to clean and maintain solid wood flooring

- Maintain1, waterproofSolid wood flooring most afraid of water. To prevent the rain water in summer. Winter to prevent the heating room running water. If you accidentally leak on the water, even a little tea, but also timely with soft cloth to clean, keep dry, so as not to push the luster, and even cause warping, cracking, mildew. If the indoor cement ground return water wet (which is at the bottom of the room the most vulnerable situation) caused by rotten, warping, peeling, swelling color variation problems such as paint, must first solve the problem back to the water wet, and then fill in the floor renovation.

- Q: Want to buy solid wood floor, heard that there is a new Dekor wood floor, the floor is a floor with the original floor. What are the difference between the floor please

- New solid wood flooring is a low-carbon sustainable development products. There are pure wood flooring natural texture, but also with a composite floor without cracking, non deformation, easy care characteristics. New solid wood in China is still a relatively new concept, it has already become the mainstream in the European market

- Q: I have heard that rubber backed throw rugs are bad for wood floors. And I am purchasing some rugs for my new home, which has wood floors.

- It isn't scratching you need to be afraid of, with rubberized backing. It is the rubber breaking down and either crumbling, or, if anything greasy got on it, it would turn to a sticky, gluey mess. Look for rugs made of natural fibers, either cotton, wool, or silk. They wear well, and won't damage your nice hardwood floors. We have wool rugs on hardwood.

Send your message to us

Yongsen Ash Wood A Class Pure Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords