Laminate Flooring

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Laminate Flooring

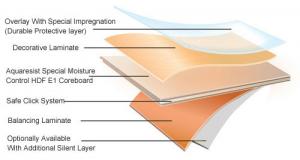

Laminate Flooring mimics the look of traditional woods while offering easy installation and lasting durability. At first glance, it can be difficult to spot the difference between hardwoods and laminate flooring. What appears to be a natural wood grain pattern is really a thin layer of decor paper (a photographic image) under a tough-as-nails protective film that is glued and pressed to a high-density backing board. Laminate flooring comes in an array of wood effects as well as stone and ceramic effects.

Characteristics of Laminate Flooring

· Resistant to UV rays

· Resistant to stains

· Not worn by furniture feet

· Resistant to cigarette burning

· Resistant household chemicals

· Healthy and ecological HDF E1

· Resistant to scratch

· Impact resistant

· Suitable for subfoor heating

AC Rating of Laminate Flooring

Class | 21 | 22 | 23 | 31 | 32 | 33 |

Marks |

|

|

|

|

|

|

Usage | Residential | Commercial | ||||

General | Medium | Heavy | General | Medium | Heavy | |

Grade | AC1 | AC2 | AC3 | AC4 | AC5 | |

EN 13329 | IP≥900 | IP≥1800 | IP≥2500 | IP≥4000 | IP≥6500 | |

GB/T 18102-2000 | IP≥2500 | IP≥4000 | IP≥6000 | IP≥9000 | IP≥11000 | |

Specifications of Laminate Flooring

Thickness | 6mm, 7mm, 8.3mm, 12.3mm, 13.5mm, 15mm |

Width | 93mm, 113mm, 126mm, 145mm, 167mm, 196mm |

Length | 1215mm, 806mm, RL(1210/805/405mm) |

Available Colors | Various designs, more than 200 colors, including Oak, Walnut, Maple, Cherry, Beech, Pine, Teak, Hickory, Merbau, Mahogany, Chestnut, Elm, Alder, Bamboo, etc. |

Available Surface | Crystal, Embossment, Paint Finish, Mirror, Matt, Wood Texture Effect, Handscraped, EIR, etc. |

Wear Resistance | AC2, AC3, AC4 |

Core Type | Moisture resistant HDF |

Edge Style | Square edges, Beveled edges |

Installation | Click system |

Waxing | Available by order |

Padding | Available by order (EVA, EPE...) |

Packing | Standard export packing |

Technical Standard | EN 13329 |

Certificate | ISO9001 / ISO14001 / CE |

- Q: Solid wood flooring after the sound how to repair?

- The floor when there are two reasons: one is the installation quality problems. Solid wood floor laying wooden keel, wooden keel laying if not smooth, the floor will appear. This situation will appear just after the shop floor.

- Q: Oak flooring and solid wood floor which is good

- But here to remind a lot of places with rubber wood posing as oak, you can not be fooled, rubber wood floors generally not more than 180 yuan / square meter!!

- Q: What is the difference between laminate flooring and solid wood flooring

- The raw materials of aggrandizement floor is mainly high density fiber board, the greatest feature of laminate flooring is good abrasion resistance, very suitable for the living room, busy occasions, is a wooden floor in the price of the cheapest varieties of a floor, colors, varieties are more special. Moreover, in the installation and maintenance is very simple, do not need to strengthen the floor waxing regularly, usually more clean and clean! Advised consumers not to buy 80 yuan / square meters of floor. More suitable for the living room, such as the flow of more decoration.

- Q: For example: Panlong eye, disk beans.

- Wood composite floors are beautiful natural wood floors, comfortable and good insulation performance strengths; and overcome the real wood floor for single body contraction, easy Qiqiao cracks deficiencies. Today, in order to survive the environment is no longer deteriorating, countries around the world attach great importance to the protection of forest resources, solid wood flooring and solid wood flooring can save rare timber resources. In addition, the installation of wood flooring is simple, under normal circumstances do not play keel. But requires ground leveling.

- Q: How do I remove a glued down engineered wood floor on a slab foundation?

- hammer drill or jack hammer with a flat end. grind the glue off with a Diamond bit floor sander

- Q: Composite solid wood flooring and laminate flooring their respective advantages and disadvantages

- Decorative effect is solid wood with natural, true. Comfortable, automatically adjust the indoor temperature and humidity on good pollution-free of course first, then three layer solid wood composite floor and keep the original wood decoration style to improve the stability of wood but Jiaogan poor a lot in the bamboo floor is decorated in the style of the song it is simple but material bamboo flooring is best to buy brand now is the good young bamboo floor processing should be very uneven, of course, strengthening also said in the past.

- Q: Three layers of solid wood composite floors or multi-storey wood composite floors

- Three betterSolid wood composite floorThe so-called composite floor. The 'composite floor' for the laminate flooring. For example, there are some (living home) multi-layer solid wood flooring, three floors of solid wood flooring and so on are one of them, so we have to understand this.

- Q: engineered hardwood flooring = how good?

- I used this in my entry way, library and hallway. I think it looks great but it does scratch very easily. When they were hanging the doors on my hall closet they sat one down and gouged the floor and it is very noticable.So unless you are getting a great bargain on it I would not recommend it to anyone else. I only bought mine because it was on clearance and it was really cheap. (Now I know why.)

- Q: Our house is a 1966 sub floor fondation, and there is original oak hardwood through out most of the house. So far, we have refinished the floors in two rooms just by sanding, conditioning and finishing with a clear coat--no stain and they're beautiful! Unfortunately, a previous owner did the unthinkable and installed engineered hardwood over the real hardwood in the front entry and two hallways. The engineered wood is ugly in comparison, and we can tell that the beautiful oak is underneath the glued down engineered flooring. Is there any chance the real wood could be salvaged if the engineered is removed, and if so, what would be the best and most economical way?

- Ya there is a chance.Pull off any trim on top of the floor in one of the areas-reducers,base board,1/4 round etc,with a pry bar try prying up a section(the begining of hallway would be a place to try).More than likely the engineered flooring is a toungue and groove or snap lock type,which is glued at the seams,and there is a underlayment of some sorts,tar paper or a foam backer.If thats the case then it will come up in big sheets,the pull and fold technique works about the best for me. Good luck

- Q: I'm wanting to put wood floors in and I've noticed that not all allow you to float them. Some have to be glued or nailed? They look the same to me. This is going in over concrete. But why don't all work for floating floors? Whats the diff?

- I would imagine is has to do with expansion and contraction properties of the different types of hardwoods.

1. Manufacturer Overview

| Location | Mudanjiang, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | 70.00% North America 10.00% Western Europe 10.00% Middle East 10.00% Domestic |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average; Low |

Send your message to us

Laminate Flooring

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 X 20'GP m²

- Supply Capability:

- 50 X 20'GP Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords