ECO Friendly Solid Kempas Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Solid Kempas Flooring:

Item | Solid Kempas Flooring |

Dimension | 18*90*900mm 18*120*900mm Optional |

Moisture Content | 8%-10% |

Joint | T&G |

Grade | AB or ABC |

Finishing | UV lacquer,natural color |

Payment Term | T/T.30% deposit, balance against copy of B/L |

Lead Time | 30 Days |

Installation | Glue, float or nail down |

MOQ | 500m2 |

2. Use & Maintain:

1) Keep the flooring dry and clean;

2) Wax the floor every 3 to 6 months to protect the floor and keeps the floor bright.

3) Don't impact the floor with heavy and hard objects. The feet of chairs and heavy furniture should be put on protective mats.

4) Prohibit exposing for long time under the intensive sunshine or soaking in water.

5) Keep the moisture connect of the room in a proper condition.

3. Advantages of Solid Kempas Flooring:

a.beautiful

b.comfortable

c. nature

4. Quick Details:

1. Hard wooden, with clear and unique texture, in different poses and with different expressions,

be full of wit and humor, It’s one kind of happy symbol, stable color, exquisite and elegant

2. It’s very attracted by USA and Canada customers

3. Formaldehyde release: E0

4. Moisture content:7%-10%(or as per customer’s requirement

5. Color::many color for option or as per customer’ requirement.

6. Type: Gloss pre-finished; Matt pre-finished and Unfinished

7. Standard size: random length(300-1750mm)*90*19mm (Or fixed dimensions as per your requirement).

- Q: Three layers of solid wood floors and multi-layer solid wood which is good

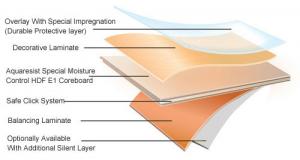

- The multi-layer solid wood is more than nine layers of single board criss cross, layers of hot pressing, with less glue, and the distribution of wells, the internal prestressing set up, enhance the stability of the whole plate, more suitable for geothermal environment.

- Q: What kind of solid wood floor

- High-grade wood: oak (220-420 yuan / square meters); jatoba (230-350 yuan / square meters), teak (270-420 yuan / square meters), Balsam (220-330 yuan / square meters of high-grade wood): Black Walnut (300-500 yuan / square meters), Asian Pear (300-450 yuan / square meters), and ebony, red sandalwood, rosewood, rosewood and other valuable timber wood flooring is made, the market price at least 500 yuan / square meters or more; (two) according to the characteristics of sales is good, affordable

- Q: I purchased engineered wood flooring, following manuf. requests, but it started to separate within a month. I pulled it all apart and GLUED it back down, removing the moisture foam barrier stuff. Now EVEN after glueing the flooring to the subfloor- it is still separating in places, not as many, but Dang! lol

- The reason is simple ! it is not seasoned well. hence it is shrinking. Go back to the supplier and demand rectification of the defects.

- Q: We are in the process of buying hardwood flooring and wow it's not easy! We found a beautiful Brazilian Cherry 1/16 x 4 3/4 but were finding through our research it gets as many good reviews as it does horrible ones. Anyone have any personal experience with this brand flooring and it's quality? How is it as far as scratching and dents? We have a 2 year old who loves to throw things so it needs to be durable. Also do we have to worry about alot of warping with the brand? Again does anyone have any personal experience? Do you have any brands you definitely would recommend? Again it has to be floating to be put on cement flooring. Thanks!

- Some engineered flooring is sort of a pressed-wood material. We have that and it wears great but over a few years, the interlocking edges are sort of curling up and that looks dumb. It is best to get genuine wood flooring that is a better investment.

- Q: What is the general brush on the surface of the wood floor is better

- The maintenance of solid wood flooring is often difficult to estimate or too high. Actually not difficult. Normal cleaning, use a vacuum cleaner on the line. But remember that the wheels of the vacuum cleaner should be fitted with a soft sleeve to prevent damage to the floor when moving. In addition, you can use the liquid wax every month to use a dedicated mop again on the line. It should be noted that liquid wax, rather than solid wax. If the use of frequent, you can change the waxing cycle for half a month, the best time to wax is the last time you hit the wax has not been completely worn. The first laying, you can play a liquid wax before construction.

- Q: Is thickness a major concern with engineered hardwood flooring? My subfloor is 3/4 ply.Here's an example.

- 3 8 Engineered Hardwood Flooring

- Q: Multi tier solid wood flooring how much money a square

- Product information and atlas. Those rough printing, the content is simple, said to wear eighteen thousand thousand words, and so on is not false propaganda, is not standardized for the manufacturers. Three see manufacturers or marketing agencies have no standardized retail price, whether it belongs to the free price of the product, if this is the case, it is impossible to brand floor. Four look at the floor surface pattern. The fuzzy texture, the color is not correct, not natural, poor sense of solid wood floor, not easy to fade, anti ultraviolet radiation, the floor is of low quality bads. Five see core material. The core material is rough, the color dark floor, the formaldehyde content surpasses the national first-class product standard, the floor comprehensive index is unqualified, belongs to the inferior product. Six see burnish degree. With sandpaper polished floor surface with proper strength, few, low-quality counterfeit products are white marks, lower than the national standard requirements of wear. Seven see stitching effect. Pumping a packet of floor, the three staggered pavement.

- Q: I know I can stencil, but the area is huge and wallpaper cutouts or boarder seems like a good idea to me. I can then seal it with many coats of some kind of low voc clearcoat. I was going to test this in one of the closets to see how it works.

- Go for it...it sounds like a great idea

- Q: What hard wood flooring is better solid or engineered. The flooring is going to be placed in a bed room and family room

- As you can see, there really are a lot of factors that go in to talking about the differences between solid and engineered wood flooring. The last statement I would make is about how much more environmentally friendly engineered flooring can be over solid. This is because you can get a far greater yield out of the finished hardwood with engineered because you are only using the finished hardwood type on the top layer. This is why engineered flooring has seen a dramatic increase in sales over the last 7 to 10 years and solid has declined. Most manufacturers inside and outside the US are retooling their factories to handle more engineered as solid will have a much smaller role in the future. Of course, like anything else, you can't make a blanket statement on this as well. Engineered, while more environmentally friendly (in concept) is a manufactured product. You have to take into account the glues that were used to press the layers together, the finish in the top layer, etc. But overall, the industry would agree that engineered hardwood flooring is the way of the future. I hope this helps you. It was a lot of information but in my opinion, the information needed to make an informed decision about what is best for you.

- Q: Advantages and disadvantages of solid wood flooring

- Stability: solid wood floor of its wood fiber unidirectional and tree core and tree edge of the tree age is different, resulting in different levels of wood density of wood, so the plate caused by the thermal expansion coefficient is different and easy to deformation. In the case of dehydration easy to sew. Strengthen the production process of the floor is wood waste processing into powder, add glue, pressed into high density plate under high temperature and pressure, and then paste the computer printing decorative paper, then coated with three two aluminum oxide coatings and wear resistant materials, finally processed into what we see shape. Strengthening plate stability is good, but because of its substrate is high density board, heat and moisture to the whole swell, if left in the installation of the contraction joints of small, easily arching, and the floor is afraid of water, water easily after expansion, not a good deal. Multi layer solid wood floor, the production process is to cut wood veneer, and then according to the wood grain crisscross with resin glue hot pressing molding. Because the structure is arranged in a crisscross pattern characteristics between the layers contain each other, so as to overcome the above wood heat expansion coefficient of eighty-five percent, the deformation is small, and the substrate core board is the selection of Eucalyptus wood is loose, the pores of wood between the loose stress can also be partially offset by an expansion of wood shrink. So its stability is much stronger than other floors.

1. Manufacturer Overview

| Location | Mudanjiang, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | 70.00% North America 10.00% Western Europe 10.00% Middle East 10.00% Domestic |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average; Low |

Send your message to us

ECO Friendly Solid Kempas Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2000 m² m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords