Yongsen Grade A Pure Africa Teak Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 22000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Tree bark

: thick 1.25px, smooth, soft, easy to break and block off. Skin yellow to grayish brown, with irregular cracks, brittle flaking. Endothelial brown, pinch easily into downy fibers.

Cross section

Heartwood clear. Heartwood when fresh yellow brown, dark brown long home atmosphere transfer. Sapwood width of about 62.5px, narrow, shallow color. Growth wheel is not obvious.

Wood properties

: wood is diffuse porous wood, sapwood narrow, width 1.5-62.5px, heartwood yellowish brown to dark brown and sapwood and obvious difference; growth ring was not obvious;

Wood has a luster, no special smell; texture until slightly staggered, the structure is very fine and uniform; the durability of wood is high, not easy to rot and insects; dry shrinkage, dry, good stability. The strength and mechanical parameters of wood are higher. Good processing performance, surface processing, paint, adhesive, etc. turning performance is good. Bending performance, grip strength. Contact with the black metal easy to rust. Air dry density 0.70-0.86g/cm3.

2、Product Characteristics

1, naturally contain heavy oil, moisture, pest control, anti termite. Teak cut down a month later, due to being changed to nutrition, mothproof effect. Also is especially resistant, teak Millennium does not rot proof.

2, micro pinhole solid structure, made of teak wood floor has both strength and toughness, good stability, normal hardwood floor installed within two years winter there will be expansion is bigger, gap up to 3 to 4 mm; and the summer and systolic bulge, easy to have the sound. Teak wood floor stability.

3, the classic color, golden brown to deep brown, soft Moxian, beautiful oil shadow, form varied texture, atmospheric, elegant.

4, teak unique mellow, insect prevention termite, anti acid, alkali, corrosion resistance. The unique flavor of the old people's brain nerve has a soothing effect, promote sleep.

5, long time, with more beautiful color.

3、Parameter

Material: Teak

Style: Modern

Standard: ISO90001

Applicable scope: bedroom

Pattern: Wood

Special purpose wear

Plate finish: good

Surface shape: paint:

Residual depression: no formaldehyde release amount: E1

Resistance: good

Wear layer thickness: 3cm

Abrasion resistance: good

Fading (stage): 1

Floor thickness: 18mm

Whether to refer to the floor: no

Color: yellow

Specifications: 910*122*18

4、Reference pictures

- Q: What is the use of solid wood floor mopping tools

- At ordinary times, the dust can be cleaned by using a vacuum cleaner or a broom, and then the water can be dried and dried to a cloth or mop which is not dripping. After the floor is best to open windows and doors, so that the air circulation, as soon as the floor dry. Drag the wooden flooring for multifunctional electrostatic mop, including: superfine fiber cloth (wet mop cloth); magnetization (MOP) composite wood floor wear-resisting layer if the damage will make the floor moisture-proof function and brightness are affected, therefore, when walking on the floor, should try to wear cloth slippers, barefoot best. Furniture legs are affixed to the end of the soft protective pad, avoiding furniture feet scratching floor wear-resisting layer, don't let the heavy goods fell wear-resisting layer. Do not use sandpaper, sanding, steel brush, strong decontamination powder or metal tools to clean the compound wood floor. If you have a cat at home, try to solve the problem.

- Q: How long is the service life of solid wood flooring?

- In the wood flooring industry, the thickness of the wood floor is often very critical, it can roughly determine the service life of wood flooring. The thicker the wooden floor, the longer the service life of the wooden floor.

- Q: How to maintain composite wood floor

- Maintenance measures:1, the room humidity should not be too large, to keep the floor dry, clean and clean, the daily use of clean mop mop mop can be. In case of stubborn stains, the use of neutral cleaning solvents should be cleaned and then wring dry cotton mop wipe, do not use acid, alkaline detergent scrub.

- Q: I am planning to install engineer wood floor over concrete in Corona, California without the moisture barrier. Anyone here done the same with no problem? thanks.

- I wouldn't take the chance. Why would you risk it? Wood, especially engineered wood, is NoT impervious to moisture. And any moisture can/likely will cause some kind of damage. I would consider the cost of the flooring, versus the cost of the moisture barrier. And the moisture barrier isn't any big deal to install, is it? Like the other guy mentioned, what does your warranty say? To me, it's not so much an issue of losing the warranty, as it is an issue of knowing what the manufacturer recommends. They made/engineered the stuff; they ought to know its limitations.

- Q: We are about to finish the floors in our basement and the guy at home depot suggested engineered wood floors instead of pergo type floors. They r real wood, do you know if this is a good product, and any negative things about it. Also the guy said it could be refinished, but it looked too thin for that to me.

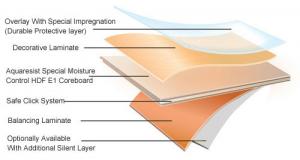

- It's a good idea. Engineered wood is 3-7 layers of thin wood with the top layer being the exotic real wood. Each layer is stacked in opposite directions. The cross -ply construction prevents the wood planks from reacting negativlely to any humidity, which can cause expansion / contraction. It's ideal for basements and can be installed directly on top of cement.

- Q: Solid wood flooring and laminate flooring which is better

- Disadvantages of solid wood flooring:1 difficult to maintain: solid wood flooring on the installation of a higher demand, once the installation is not good, will cause a series of problems. The problem of floor installation complaints has been high on the problem.2 high prices: due to various factors, the solid wood flooring has been maintained at a higher price, and in the short term there is no possibility of downward. It flowers in the wood floor without paying the money, the family still have to weigh a tight budget

- Q: Restaurant can not use solid wood flooring?

- Best kitchen tile. Because the kitchen will often have water on the ground, the appropriate comparison, more suitable for laying tiles. If you really like wooden floor, you can shop imitation wood tiles. The advantages of kitchen porcelain tile:Not afraid of water. Kitchen floor will often have water, wood floor water on the deformation of a bubble. Tile floor, wipe dry.

- Q: How do I get rid of glue haze on my engineered hardwood floor?

- mineral spirits

- Q: Model 8703, the solid wood floor of a plate

- Wood floor types are: solid wood flooring, laminate flooring, solid wood flooring, bamboo flooring, such as more than a dozen. To realize the choice of the kind of floor, and then have the goal to focus on the selection decision.

- Q: Is thickness a major concern with engineered hardwood flooring? My subfloor is 3/4 ply.Here's an example.

- I really don't now much about this, but this site also helped me a lot goo.gl/dGD8qO

Send your message to us

Yongsen Grade A Pure Africa Teak Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 22000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords