Laminate Flooring Ratings

Laminate Flooring Ratings Related Searches

Laminate Flooring Cost Laminate Flooring Brands Laminate Flooring Instalation Garage Laminate Flooring Laminate Flooring For Sale Acclimate Laminate Flooring Laminate Flooring Tape Exterior Grade Laminates Nirvana Laminate Flooring 12 Laminate Flooring Under Laminate Flooring Formica Laminate Flooring Trim Laminate Flooring Kitchen Laminate Countertops Kronotex Laminate Flooring Luxury Flooring Formica Laminate Finishes Formica Laminate Samples Server Room Flooring Engineered Timber Flooring Prices Soundproofing Floors Warm Flooring For Bathrooms Cold Rolled Steel Grades Low Pressure Laminate Manufacturers Linoleum Flooring Lvt Flooring Linoleum Flooring Installation Glossy Laminate Countertops Floating Flooring Shaw LaminateLaminate Flooring Ratings Supplier & Manufacturer from China

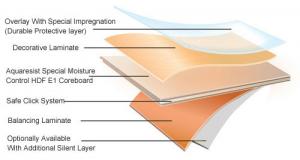

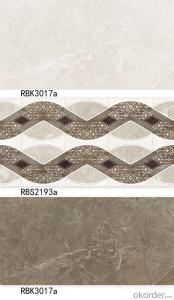

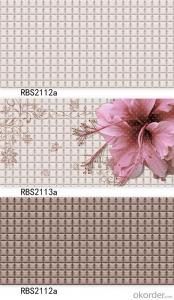

Laminate Flooring Ratings encompasses a diverse range of high-quality flooring options that cater to various interior design preferences and requirements. These products are designed to provide durability, style, and comfort, making them ideal for both residential and commercial settings. Laminate flooring is known for its ability to mimic the appearance of natural materials such as wood and stone, while offering the benefits of being more affordable and easier to maintain.Laminate Flooring Ratings products are widely used in various applications, including living rooms, bedrooms, kitchens, and offices. They are particularly popular in high-traffic areas due to their resistance to scratches, stains, and fading. Additionally, these flooring options are suitable for use in areas prone to moisture, such as bathrooms and basements, as they are less susceptible to water damage compared to traditional hardwood flooring.

As a reputable wholesale supplier, Okorder.com offers an extensive inventory of Laminate Flooring Ratings products, ensuring that customers have access to a broad selection of styles, colors, and finishes. This extensive range allows customers to find the perfect flooring solution for their specific needs and preferences, while also benefiting from competitive pricing and efficient delivery options.

Hot Products