High-Pressure Decorative Laminates with Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

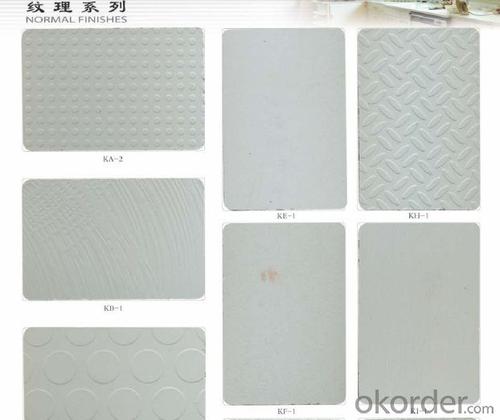

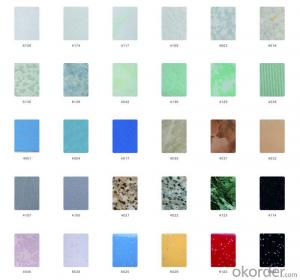

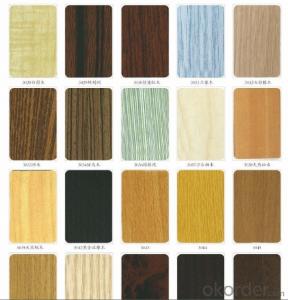

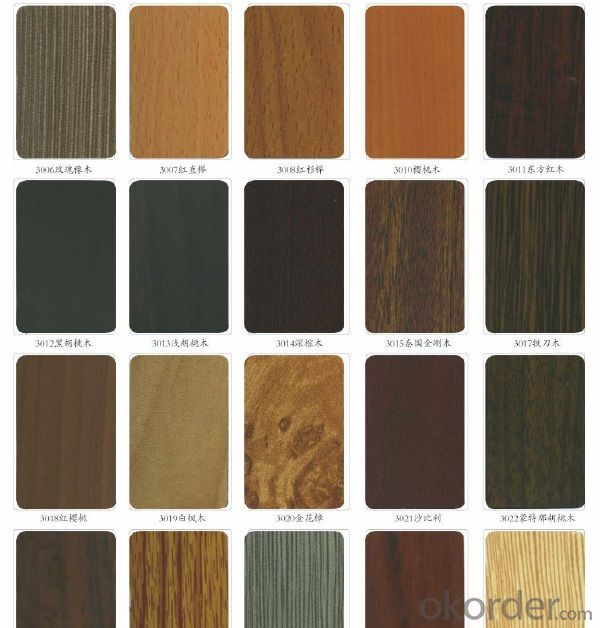

3. Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. port of shipment Qingdao, China

6. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

7. delivery time It depends on the specific order quantity

8.minimum order quantity 2000 PCS

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: What is the fire cut off?

- When the fire down the non-burning wall ~ do the role of isolation from the fire

- Q: Decoration materials fire rating

- Architectural design code for fire protection

- Q: Is plastic as a fireproof material?

- No, generally with pvc steel

- Q: Short point is to do hand copy

- Several common fire fighting methods: 1, furniture, bedding and other fire: the general use of water fire. With water around the items such as the basin and so on to the flame on the water, but also the water pipe connected to the faucet sprinkler fire; at the same time the burning point near the combustible humidification. But the oil, electrical fire can not use water to fire. 2, electrical fire: household appliances or lines on fire, we must first cut off the power, and then dry powder or gas fire extinguisher, can not directly splash water to prevent electric shock or electrical explosion wounding. 3, the TV fire: TV in case of fire, never water, you can cut off the power, with a quilt to cover it. Fire, only from the side close to the TV, to prevent the camera tube explosion wounding. If the use of fire extinguishers fire, should not be directed to the TV screen, so as to avoid the sudden cold after the heat and explosion. 4, the pan fire: the oil pan should quickly shut down the stove gas valve, directly cover the lid or cover with a wet cloth, but also to the pot put the chopped vegetables to cool the fire, the pot smooth from the fire, After cooling to open the lid, do not pour water to the oil pan. 5, gas tank fire: use wet bedding, clothing and other cover fire, and quickly close the valve. 6, the body of the fire, do not run around, can be used to roll or heavy clothing to suppress the flames. Wearing a wet towel, handkerchief and so cover your nose and mouth, try to make the body close to the ground, bending or creeping forward.

- Q: Performance and Difference of Rockwool and Glass Fiber Fireproof Materials

- Rock wool and glass wool fire rating are all A-level rock wool high temperature of 800 degrees glass wool high temperature 450 touch tiger whip mortar Zhuang Huan Biao cloth wave density rock wool relative weight of some glass wool bulk light from the waterproof performance or glass wool better some

- Q: Members colleagues, brother just into the Bank, it is necessary to use the Mylar film, what Mira is the material. Thank you more

- 1 Ingredients Mylar Sheet (MYLAR Sheet) PET polyester film is a film made by the reaction of dimethyl terephthalate and ethylene glycol under the aid of a related catalyst, followed by transesterification and vacuum polycondensation, biaxially stretching The 2 classification Mylar film appearance of milky white, black, natural, transparent color and other color classification. Mylar tablets have a variety of materials, such as PET Mylar, PVC Mylar, PC Mylar, Fire Mile and so on. Applications are divided into: insulation, cushioning, wear-resistant, sealed and the appearance of decorative type Mylar. 3 features a stable, straight and excellent anti-tear strength, heat and cold, moisture and water resistance, chemical resistance, and has superior insulation properties, excellent electrical, mechanical, heat resistance, chemical resistance. 4 use can be used for motors, capacitors, coils, cables, insulation materials, but also with the barley paper made of composite insulation materials. It is widely used in electrical insulation industry, suitable for electronics, household appliances, instruments, monitors, motor slots, computers and peripheral equipment 粻 hungry thirsty leek blood clot gasket, file, screen and protection. Attachment: can replace the general tape, suitable for electronic components in the machine when packaged for packaging, so that electronic components can be used in the more secure. Hope to help you! If you need to purchase Mylar tablets can contact our company absolutely cheap price for quality goods! Hope to create a win-win with your company!

- Q: What are the building firefighting materials?

- Refers to the "fire-retardant materials will be fixed from the heart of Jia Yanyan melancholy": in the fire products as the 18 categories, sub-categories are divided into: decorative fire-retardant paint, steel fire retardant coating, other fire retardant coating , Fire blocking materials, flame retardants, fire glass, intumescent fire-resistant materials.

- Q: How to brush fire paint

- The surface clean, spray and brush can be

- Q: What is Class A Fire What is Class B Fireproof?

- B is a combustible material; B2 is a combustible material; B3 is a combustible material; B1 is a combustible material; B2 is a combustible material; B3 is a combustible material. This is divided by the oxygen index. For example, see the "interior decoration design fire safety norms."

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability UL94 grade is the most widely used standard for combustible properties of plastic materials. It is used to evaluate the ability of the material to be extinguished after being ignited. According to the burning speed gallbladder Ding book scratching calcium difference water to promote the alarm, burning time, anti-drop ability and drop beads can burn a variety of judging methods. Each test material can be a lot of values ??depending on color or thickness. When a material of a product is selected, its UL grade shall meet the thickness requirements of the wall part of the plastic part. UL grade should be reported along with the thickness value. It is not enough to report only UL grade without thickness. Plastic flame retardant grade by HB, V-2, V-1, to V-0 step by step increase. 1.HB: UL94 standard in the bottom of the flame retardant grade. Requires a sample with a burning rate of less than 40 mm per minute for samples of 3 to 13 mm; a sample less than 3 mm thick, a burning rate of less than 70 mm per minute; or extinguished at 100 mm mark. 2. V-2: After two 10 seconds of burning test, the flame was extinguished in 60 seconds and no burner could fall. 3.V-1: After two 10-second burn tests on the sample, the flame was extinguished in 60 seconds and no combustibles could fall. 4.V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds and no combustibles can fall.

Send your message to us

High-Pressure Decorative Laminates with Cheap Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords