High-Pressure Laminates Decorative with Colorful Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

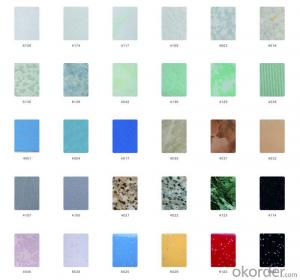

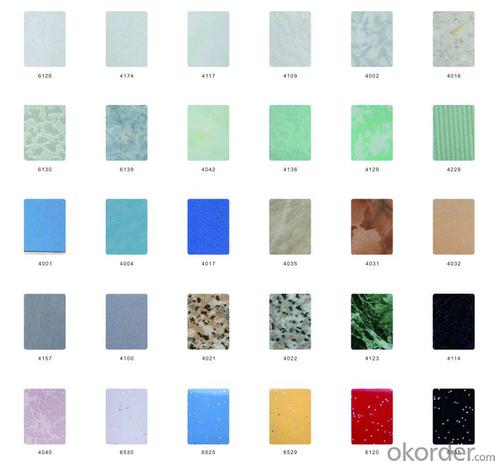

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

11) Healthniness and environment protection

12) Easy be cut, easy be edge-covered in machine

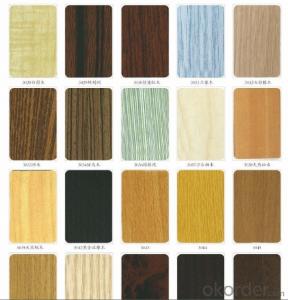

3. Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. port of shipment Qingdao, China

6. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

7. delivery time It depends on the specific order quantity

8.minimum order quantity 2000 PCS

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: Conventional gypsum board fire rating is several levels?

- B1 level, if installed on the steel keel on the gypsum board, can be used as a Class A. I hope I can help you.

- Q: Building ceiling material fire rating

- Divided into four grades, non-flammable, flammable, flammable, flammable...

- Q: Decoration materials fire rating

- Fire protection and other factors are dependent on the proportion of locally used wood finishes and the fire rating of the wood finish. All the light steel keel gypsum board A-class, if the wood fineness is small, and also reached B1 level, can also be considered A level; if the wood surface up to B2 level, the overall can be B1 level public buildings A residential building B1 level

- Q: What kind of good insulation materials for cold storage?

- Polyurethane spray ah urethane large board rock wool board glass wool board

- Q: Rubber insulation material fire it?

- Fire (he is only flame retardant and not non-flammable) B1 and B2 level Ji Ji rush to kill the ghosts only Han Li is not the flame retardant coefficient of low smoke density of a standard is not a standard in a density (density related to the effect of insulation ) Sure that you have fire against you

- Q: Rock wool board for building fireproof materials need to test what the project, according to what is the specification?

- The main detection capacity is not up to standard according to GB ah

- Q: What is the meaning of the plastic raw material fire rating HB?

- HB is the lowest level of fire rating, it can be said is not fire.

- Q: B1 refractory material refractory time long?

- At present, there are five main grades of fire protection: Class A: non-combustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger. In addition, according to different standards, the classification of fire materials are not the same: DIN4102: A1, A2, B1, B2, B3EN-1: A1, A2, B, C, D, E, FB1 fireproof materials, refractory time Look at the specific parts, see the following figure:

- Q: Ul94v-0 refers to the fire level or a material

- 【UL94V-0】 refers to the plastic material of the fire rating (flame retardant grade). Plastic flame retardant grade from HB, V-2, V-1 to V-0 step by step increase: HB: UL94 standard in the bottom of the flame retardant grade. It is required that for samples of 3 to 13 mm thick, the burning rate is less than 40 mm per minute; samples less than 3 mm thick, the burning rate is less than 70 mm per minute; or extinguished before the 100 mm mark. V-2: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. There can be a burning thing falling. V-1: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. Can not have a burning thing falling. V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds. Can not have a burning thing falling. Flammability UL94 grade Flammability UL94 grade is the most widely used combustible performance standard for plastic materials. It is used to evaluate the ability of the material to be extinguished after being ignited. According to the burning speed, burning time, anti-drop ability and whether the beads can burn a variety of judging methods. Each test material can be a lot of values ??depending on color or thickness. When a material of a product is selected, its UL grade shall meet the thickness requirements of the wall part of the plastic part. The UL rating should be reported along with the thickness value, reporting only UL grade without thickness is not enough.

- Q: How to brush fire paint

- 1, before the construction must be on the base (coated material) to clean up, remove the ash, oil and paint to be debris. Wood base should reach the natural dry state, water content <10%. 2, stir even after brushing to ensure the construction quality and product performance. 3, should be above 5 ℃, within 24 hours after construction to avoid rain. 4, the coating is generally coated with two layers, if necessary, can be coated with three layers, or cover the light again, Tu finished the first time, the natural dry after the next layer of construction. Every time the brushing surface shall not be leaked. Per square meter with the amount of ≥ 500g, to a fire safety standards. 5, brushing process using brush, spray or roller, brushing evenly. Brush the direction to be consistent, do not cross or repeatedly brushing. Note winter construction should be above 5 ℃, summer should be below 35 ℃, to avoid freezing or overheating.

Send your message to us

High-Pressure Laminates Decorative with Colorful Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords