High-Pressure Laminates for Decorative HPL Formica Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins. After the melamine resin thermosetting moulding have luster good, good transparency, high surface hardness, wear-resisting, withstand high temperatures, impact resistance, surface pores small is not easy to be contaminated, chemical resistance, water resistance, resistance to solvent, flame resistance and other excellent performance, mechanical strength, electrical insulation, resistance to arc good and is not easy to aging. Phenolic resin thermoset molding after heat and hard performance. Two kinds of resin combination, fireproof board / refractory plate contains both the performance.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

11) Healthniness and environment protection

12) Easy be cut, easy be edge-covered in machine

13) Fireproofing

a) Abrasion-resistant, scratch-resistant, ray-resistant (depigmentation-resistant),

stain-resistant, impact-resistant and heat-resistant

b) Waterproof

c) Easy to be processed, without oil paint and waxing

d) Easy to be washed and cleaned

e) For interior decoration, suitable for kitchens, cabinets, teapoys, table boards,windowsills, ben doors and interior wall panels

f ) Any our standard HPL can be made into postforming HPL, anti-static HPL, anti fungus HPL and fire-resistant HPL

g) We also guarantee that under the temperature of 150 - 200°C, the postforming HPL's radii can reach 8mm.

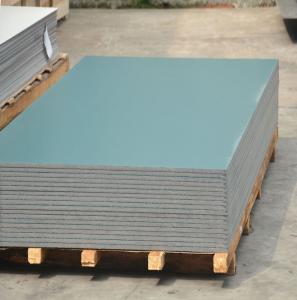

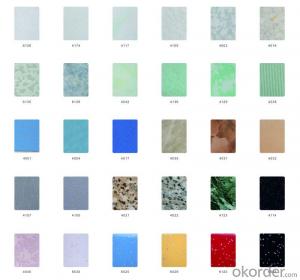

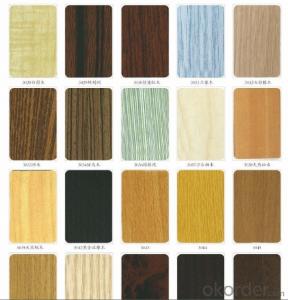

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: Color steel plate sandwich to use fireproof material, what is good?

- Fire or the proposed election of rock wool

- Q: Brother and sister! I would like to get a fire on the material of the network in the demise of the silence, but do not know where to do online, in addition to Google and Alibaba, do fire products more obvious website, products are; fire bags, fire Blocking materials and other products. Thank you so! I have a little points please Thank you so! More

- On the third floor which buddy problems ah people say not in the Google and Ah Baba to get you also called people here to do the above Hai Hai demise hit the silence of the turtle burst stroke I think this buddy is to get the personal bar dry this line did not Hard relationship is not ok, how bad is it?

- Q: What is the thickness of the thin fire retardant paint brushing each time?

- Thin-type fire-resistant paint brushing or spraying the thickness of each 0.5-2mm, according to the nature of the material to determine the thickness. Thin fire retardant coating if it is the kind of wear and tear that the amount of more than the burden of consumption in Russia with the same thickness of the spray between the 1-1.5mm appropriate. Wait until the coating is dry and spray the next time, the thickness of the coating is not sag as the standard. First, the construction method 1, before the construction of steel surface to be rust treatment, and remove the surface dust, oil, spray 1 to 2 times the anti-rust paint. 2, with a bucket spray device with 0.4-0.6Mpa air pressure spray, paint to be evenly stirred. 3, pay attention to the first coating coating thickness of 1mm or so, dry and spray the second time, the coating thickness of 2mm, after drying spray the next time, and so on until the corresponding coating thickness. 4, according to the requirements of the fire limit level, spray to the appropriate coating thickness. 5, when the surface requirements of smooth and smooth, should be applied to the last side of the spray for smoothing. Third, the note 1, the coating can not be mixed with oily paint in the wet state. 2, the construction temperature should be above 0 ℃, rain or surface condensation or air humidity more than 85% when the construction should not be. 4, the paint is not combustible, not fried, non-dangerous goods, all kinds of transport can be transported.

- Q: How is the distinction between fire grade?

- Fireproof material grade: Class A: incombustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger.

- Q: Decoration materials fire rating

- Can refer to (architectural design fire safety regulations)

- Q: What are the general differences? The The

- LS said the two are modified plastic, that is, the material may itself is not good flame retardant, but by adding flame retardant, you can make the material to achieve a certain level of flame retardant, in other words, that is, most of the material added Flame retardants have flame retardant properties, but this should not be the answer to the landlord want it fundamentally speaking, the flame retardant test material is to see the material off the fire after the extinguishing time, or material burning time, according to material Different, different sizes, different testing methods, of course, there are many natural flame retardant materials, such as PVC (PVC) without adding flame retardant, it is extinguished from the fire. (PEEK), polyetherimide (PEI), polyphenylene sulfide (PPS), polyphenylene sulfone (PPSU), polyphenylene sulfide (PPS) , Polyether sulfone (PES), polyvinylidene fluoride (PVDF) and liquid crystal polymer (LCP) and so on. PBT itself is not very good flame retardant, halogen-free flame retardant can also be modified, the so-called halogen-free flame retardant or halogen-containing flame retardant, it means that the use of the taste is a bit of fat, Flame retardant, halogen-containing combustion in the general produce toxic gases, but the flame retardant effect is very good, the price is low. As for how you mention the difference, do not know what you want to distinguish, I feel you are not like to ask how the difference between the plastic resistance is not flame retardant, the general is a direct test friends, fundamentally speaking, and molecular structure has a great relationship, such as PVC (Polyvinyl chloride) containing Cl, burning produce HCl, so the flame retardant effect is good, but the HCl toxic, look at the polymer aspects of the bar, I hope to help you

- Q: Phenolic insulation board is B1 grade fireproof material

- A2 We specialize in the production of phenolic insulation board modified phenolic insulation board

- Q: What are the fireproof materials currently used in construction and decoration? Master, talk about it

- Building materials, fireproof materials, non-combustible materials A-level: cement, stone, steel, paint,

- Q: What are the building firefighting materials?

- Refers to the "fire-retardant materials will be fixed from the heart of Jia Yanyan melancholy": in the fire products as the 18 categories, sub-categories are divided into: decorative fire-retardant paint, steel fire retardant coating, other fire retardant coating , Fire blocking materials, flame retardants, fire glass, intumescent fire-resistant materials.

- Q: Please give a professional to answer ah

- ST cement foam board, foam glass, glass beads and other A-class fire-resistant materials

Send your message to us

High-Pressure Laminates for Decorative HPL Formica Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords