High-Pressure Decorative Laminates for Kitchen Used

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

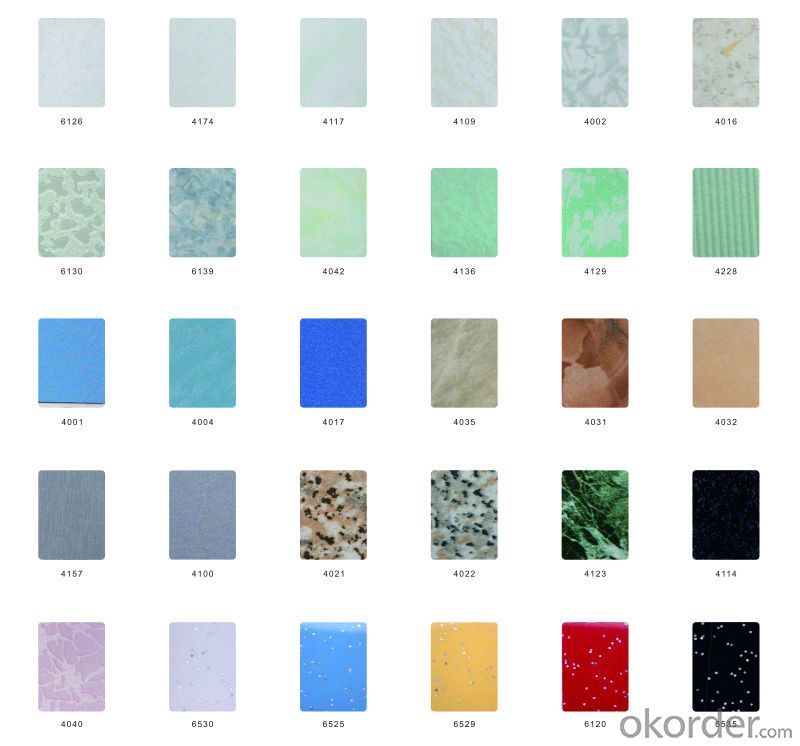

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

6 usage. 1) Can be widely used for decorative materials of interior walls, bathroom, sliding doors, ceilings, kitchens, wardrobe etc.

2) Can be used for the body of furnitures and kitchens.

3) Can be wiedly used for hotel, clubs, bars, restaurant and so on.

4) Can be widly used for box to gift, shoes,wine etc.

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q: Color steel plate sandwich to use fireproof material, what is good?

- Rock wool board insulation, sound insulation effect is good

- Q: Is it permissible or permitted to block the use of fireproofing in cable ducts?

- Construction electrical engineering construction quality acceptance in Article 12.2.1 Article 6 provides "laying in the shaft and different fire partitions of the bridge, according to the design requirements of the location, there are fire blocking measures." This lazy rough short Nao stubble Preserving flowers in the "design requirements of the location" is generally in the fire partition wall.

- Q: Are you using fireproof materials for decoration?

- Sure to ah, such as the switch panel burned, there must be a layer of Shuo plastic bedding, not easy to cause flammable, but also early hair problems

- Q: A1 grade external wall insulation materials which

- As the name suggests, A-class fire insulation material that is a fire rating of A-class fire insulation materials. Class A materials include A1: single inorganic incombustible; A2: composite organic noncombustible, that is, composite materials. Class A is non-combustible materials: WW inorganic reactive wall insulation materials, cement foam insulation board, glass beads insulation mortar, rock wool board, glass wool board, foam ceramics. Class A is a non-combustible material with low density, low thermal conductivity, high pressure capacity, convenient construction, economical and durable characteristics, widely used in hot pipes, thermal equipment and other industrial piping equipment and industrial building insulation materials and insulation Industrial and civil construction envelope insulation, insulation, sound absorption materials. Because of its good thermal stability, and more for the steel structure of the fire protection coating material.

- Q: Insulation class fire rating non - combustible A - level and A2 - level difference

- A1 level is absolutely non-flammable and no smoke produced by the A2 non-combustible but there is a certain smoke poison gsy inorganic rigid foam insulation board details contact by registered name hit my cell phone

- Q: How is the distinction between fire grade?

- How is the distinction between fire grade?...

- Q: What are the general differences? The The

- Flame retardant grade PP, flame retardant PP, flame retardant PE, flame retardant PB, flame retardant PBT, flame retardant PC, flame retardant Burning PC / ABS alloy, and now there are still halogen flame retardant, halogen-free flame retardant research a lot, but the product stability and flame retardant effect has yet to be improved. Flame-retardant material testing methods are: commonly used flame-retardant material testing methods, including horizontal and vertical combustion, oxygen index method, NBS smoke box method, thermal analysis, cone calorimeter method. The simplest is the direct burning about, intuitive to see is from the fire to try Ding Bai shares of fat Karma mixed with the stem that is put out or continue to burn, burning time.

- Q: Production of fire paint business should have what qualifications

- (License, organization code, tax registration certificate, system certificate, etc.) and type approval certificate, such as the new plant had to use the environmental assessment and other information (such as the use of environmental protection,

- Q: Rock wool board for building fireproof materials need to test what the project, according to what is the specification?

- Compression, Tensile, Acidity Coefficient, GBT-2017 Building Exterior Wall External Thermal Insulation with Rockwoel Plate Rover Porcupine Cabbage Cabo Goggles. Dayton fire insulation materials Co., Ltd

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability UL94 grade is the most widely used standard for combustible properties of plastic materials. It is used to evaluate the ability of the material to be extinguished after being ignited. According to the burning speed gallbladder Ding book scratching calcium difference water to promote the alarm, burning time, anti-drop ability and drop beads can burn a variety of judging methods. Each test material can be a lot of values ??depending on color or thickness. When a material of a product is selected, its UL grade shall meet the thickness requirements of the wall part of the plastic part. UL grade should be reported along with the thickness value. It is not enough to report only UL grade without thickness. Plastic flame retardant grade by HB, V-2, V-1, to V-0 step by step increase. 1.HB: UL94 standard in the bottom of the flame retardant grade. Requires a sample with a burning rate of less than 40 mm per minute for samples of 3 to 13 mm; a sample less than 3 mm thick, a burning rate of less than 70 mm per minute; or extinguished at 100 mm mark. 2. V-2: After two 10 seconds of burning test, the flame was extinguished in 60 seconds and no burner could fall. 3.V-1: After two 10-second burn tests on the sample, the flame was extinguished in 60 seconds and no combustibles could fall. 4.V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds and no combustibles can fall.

Send your message to us

High-Pressure Decorative Laminates for Kitchen Used

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords