High-Pressure Laminate Material Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

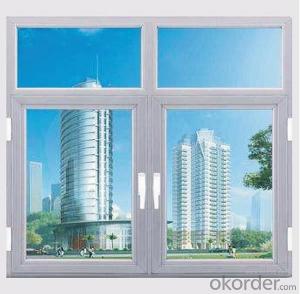

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

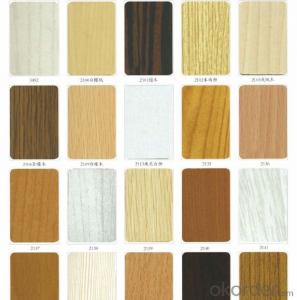

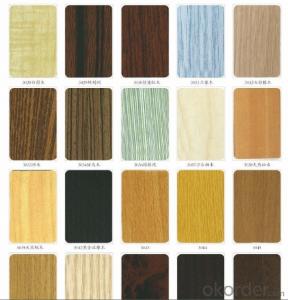

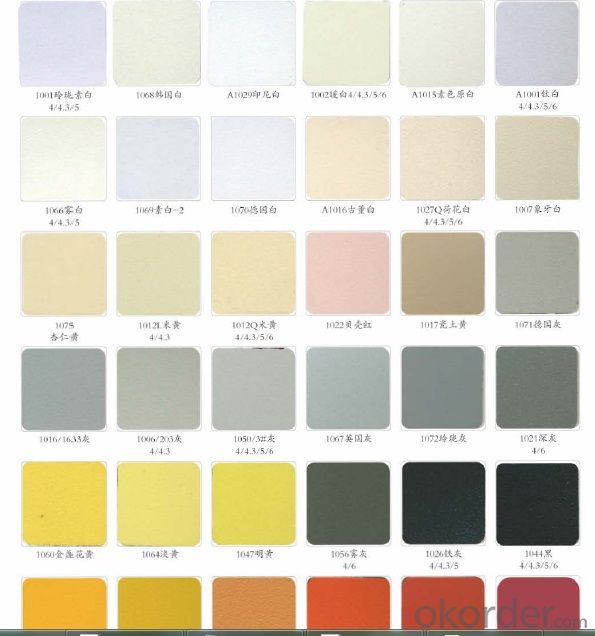

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special product.

- Q: what is the price

- This problem you are online to ask, it seems that you do not understand the decoration, but also to undertake the decoration of KTV, it is not willing to tell you.

- Q: What is the fire cut off?

- Partition refers to the facade that is dedicated as a compartmentalized space. Fire cut off is the fireproof material to do!

- Q: Gypsum board with fire performance is it?

- Gypsum board is the main component of calcium sulfate, chemical formula CaSO4. Melting point 1450 ℃, the relative density of 2.96, insoluble in water. Its dihydrate CaSO4 ? 2H2O is commonly known as gypsum (or gypsum). Hemihydrate CaSO4 ? 1 / 2H2O called plaster (or gypsum). Gypsum is a mineral, for the monoclinic crystal, was plate or fibrous, there are fine lumps, was light gray, reddish, light yellow or light blue. Gypsum heated to 128 ℃, lost most of the crystal water, into a plaster; 163 ℃ above, all the loss of crystal water. The plaster of the plaster is mixed with the plastic, but soon hardened to become gypsum. This process releases a lot of heat and swells, so it can be used for casting models and sculptures including gypsum pliers, with fire resistance.

- Q: Glass curtain wall and floor between the gap how to deal with, seeking expert solution?

- Figure, 1.5mm galvanized steel plate up and down. The middle of 100 thick fire rock wool.

- Q: How is the distinction between fire grade?

- How is the distinction between fire grade?...

- Q: Fire protection requirements for indoor ceiling materials

- In the building interior design fire, the common parts of the common technical requirements. 1. Ceiling (ceiling) In all the interior decoration of the fire design, the ceiling fire design in the most important position. This is because the fire is burning up the fire, the ceiling first and directly accept the fire test; the same time, there is a direct impact on the evacuation, will directly constitute a threat to the safety of evacuated personnel. Therefore, in the interior ceiling decoration design, should give full consideration to its fire problem. "Fire protection within the building design fire code" on the different civil buildings of indoor ceiling material fire performance has a detailed requirement. 1) single-layer, multi-storey civil building ceiling materials, generally should be non-combustible materials. The following buildings can be used in the construction of flame-retardant materials: ① construction area ≤ m2 of the station, the terminal waiting (boat) room, restaurants, shopping malls, etc .; 粻 open outline satin and other persuasion stitch ② each floor area < 1000m2 or the total area of ??<3000m2 shopping malls business hall; ③ no central air-conditioning system hotels, hotels, office buildings and complex buildings; 2) high-rise residential building ceiling materials in addition to two types of high-rise civil buildings can be used to build the ceiling of flame retardant materials, the other should be used non-flammable materials. 3) underground ceiling of civil buildings should be used non-flammable materials.

- Q: Construction of the building when the need to set up a firewall, the most common way is to use solid brick, then do not have this, out of indignation when the fissure when the river with what other can replace, which is better? More

- There are a lot of fireproof materials, but the price is generally higher than ordinary bricks, if you use other fireproof materials can certainly replace, but your cost will increase, so for investors is not worthwhile.

- Q: What is the raw material for producing fire retardant coatings?

- The specific I can not say that it is a trade secret but can generally talk about 1. Non-intumescent concrete fire retardant coating, is made of inorganic adhesives and organic adhesives, and fire-resistant insulation materials by a reasonable modulation of the fire insulation Coating material. Its low density, good adhesion, good insulation, anti-aging, weather resistance, easy construction. Once the fire occurs on the surface of the coating will form a barrier oxygen, fire glaze layer, in the 2h range can guarantee the concrete components do not crack, do not collapse. 2. Thick steel structure fire insulation coating by the porous insulation materials, adhesives and performance moderators, non-asbestos. The protected steel structure, due to the thermal insulation coating, has a function of suppressing the combustion and preventing the fire from escaping the function of the flame, which significantly improves the fire resistance level. 3. Thin steel structure Fireproof coating is made of binder and refractory insulation material grinding, mixing, mixing made. The coating is water-based and has no pollution to the environment, but the construction and storage temperature should be & gt; 0 ° C. Spraying wipes are best to spray the best. After coating film, resistant to moisture, weather resistance, corrosion resistance, anti-aging also adjustable the corresponding color. The effect is convex and numb. According to the project requirements, but also smooth.

- Q: Plastic products in the classification of fire levels is how the standard ah?

- About UL94 Flammability Rating Series Description UL94 Flammability Rating Series Introduction Introduction UL94 - Tests the flame resistance of plastic materials in equipment and installations. This standard is based on the flame resistance of plastic materials, including a range of each level. The rank represents HB horizontal combustion (HorizontalBurn), with only one grade possible. V vertical burn (VerticalBurn), there are three levels: V-0 is the highest, V-1 is low, then V-2.5V vertical combustion (VerticalBurn), the use of large 125mm flame, there are 1 or 2 level 5V -A or 5V-B. VTM vertical thin material (VerticalThinMaterial), and V grade of the same type of possibility, but behind the TM plus TM.

- Q: Basement ceiling extrusion board insulation material fire rating What are the requirements? What are the requirements of fire acceptance?

- Belong to the flammable material is absolutely can not be used in the ceiling, to use the flame retardant material Caixing, fire technical specifications are required.

Send your message to us

High-Pressure Laminate Material Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords